sales@loadcellsensor.com

sales@loadcellsensor.com

Belt Weigher Load Cell 0-500kg Roller Conveyor Load Cell

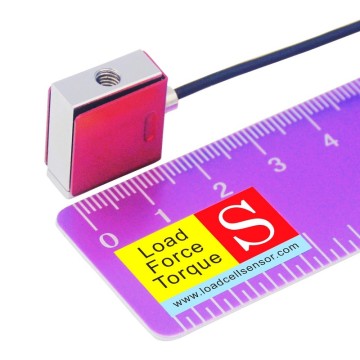

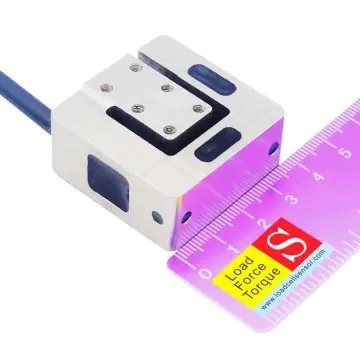

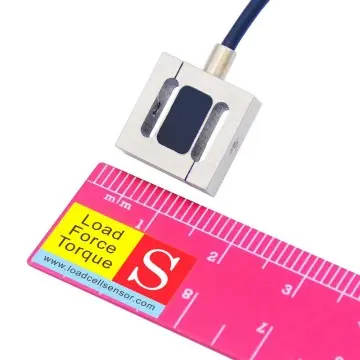

The LCGD bending beam load cell offers a dependable and rugged solution for demanding industrial weight measurement tasks. Crafted from 17-4PH stainless steel, it is IP68 hermetically sealed, making it suitable for harsh environments involving dust, water spray, and rigorous sanitation procedures. Its solid structure and high ingress protection provide extended durability and stable operation, even in heavy-duty usage scenarios.

With available load ranges from 5kg up to 500kg, the LCGD belt weigher load cell features a single-ended beam configuration designed to ensure precise readings. Built-in temperature compensation maintains measurement accuracy across varying climate conditions, which is essential in industrial zones prone to temperature swings. The bellows-style housing enhances environmental resistance without sacrificing sensor sensitivity or repeatability.

Widely adopted in the weighing industry, the LCGD stands out due to its adaptability, performance, and economical pricing. Priced at just $99 per unit, it competes directly with established models such as HBM Z6FC3, Mettler Toledo MTB, Tedea-Huntleigh 355, Celtron HBB, and others like Anyload 563RS, Flintec SB8, and Laumas FCOL. Its broad compatibility and direct interchangeability make it a preferred replacement option for existing setups, particularly for OEMs and integrators seeking reliable alternatives.

Typical Applications of the LCGD Weight Sensing Sensor:

- Hopper and Vessel Weighing: Perfect for integrating into hopper systems and small storage tanks, the LCGD ensures accurate weight monitoring for raw materials or batched contents. Its compact form factor and moisture resistance make it suitable for dusty or humid conditions.

- Conveyor Belt Weighing: In industries handling bulk materials, conveyor systems utilize LCGD belt conveyor load cell to track flow rates with high precision. The sensor’s consistent accuracy helps control production outputs and minimize resource loss.

- Automated Bagging Lines: LCGD precision load cells are integral to high-speed packaging lines, especially for dosing and filling bulk materials like powders or grains. Their quick response and dependable output help maintain operational consistency and reduce material overfill.

- Livestock and Feed Weighing: In poultry and animal farming, these beam type load cells support batching of feed and weighing of live animals. Their hygienic stainless steel body and resistance to corrosion make them ideal for use in clean, food-safe areas requiring regular washdowns.

- Food & Beverage Manufacturing: From ingredient dosing in mixing tanks to weight monitoring in bottling stations, LCGD weight machine load cells play a critical role in ensuring accuracy and maintaining production standards. Their IP68 protection allows them to withstand aggressive cleaning cycles.

- Gravimetric Feeding Systems: In controlled material dosing setups, the LCGD temperature compensated load cell provides real-time weight feedback essential for automated blending or extrusion processes, ensuring precise ingredient proportions.

In summary, the LCGD stainless steel load cell delivers a powerful blend of precision, longevity, and affordability. Whether used in production facilities, packaging operations, or agricultural systems, its proven design and wide compatibility offer a practical, long-term force sensing solution for dynamic industrial environments.