sales@loadcellsensor.com

sales@loadcellsensor.com

Navigating the 2025 Technology Trends in Load Cells Your Ultimate Guide to Best Miniature Load Cells

In the fast-evolving world of technology, understanding the trends that shape industries is crucial, particularly in specialized areas like load cells. As we navigate through the anticipated technology trends for 2025, it's essential to shine a spotlight on Miniature Load Cells, which are becoming increasingly vital across various applications. These compact sensors not only offer precision and reliability but also adapt seamlessly to the demands of modern engineering and digital solutions. This guide aims to explore the best miniature load cells available in the market, focusing on solutions tailored for different types of applications. Whether you are in manufacturing, robotics, or material testing, our insights will help you make informed decisions that align your operations with the latest technological advancements. Join us as we delve into what makes miniature load cells a cornerstone in the future of load measurement.

Understanding the Impact of 2025 Technology Trends on Load Cell Development

The technological advancements anticipated for 2025 will significantly influence the development of load cells, particularly miniature load cells. As highlighted in the "2025 Frontier Technology Trends Report" by FTSG, innovations such as artificial intelligence, robotics, and quantum computing will drive the next wave of enhancements in sensor technologies. The integration of AI into load cell designs will enable smarter and more responsive systems, making it possible to gather and analyze data in real-time, thus enhancing precision and reliability in various applications.

When selecting miniature load cells, consider the following tips: First, assess the specific requirements of your application, including the load capacity and environmental conditions. Choosing load cells with appropriate materials and technology ensures longevity and accuracy. Second, stay informed about industry trends; for instance, as smart technologies become more prevalent, opting for load cells that offer connectivity features may provide significant advantages in data management and analysis.

Additionally, keep an eye on the increasing relevance of quantum computing in sensor technology. As these systems become more mainstream, their potential to revolutionize data processing will impact load cell performance. By understanding these trends and their implications, you can better navigate the evolving landscape of load cells come 2025.

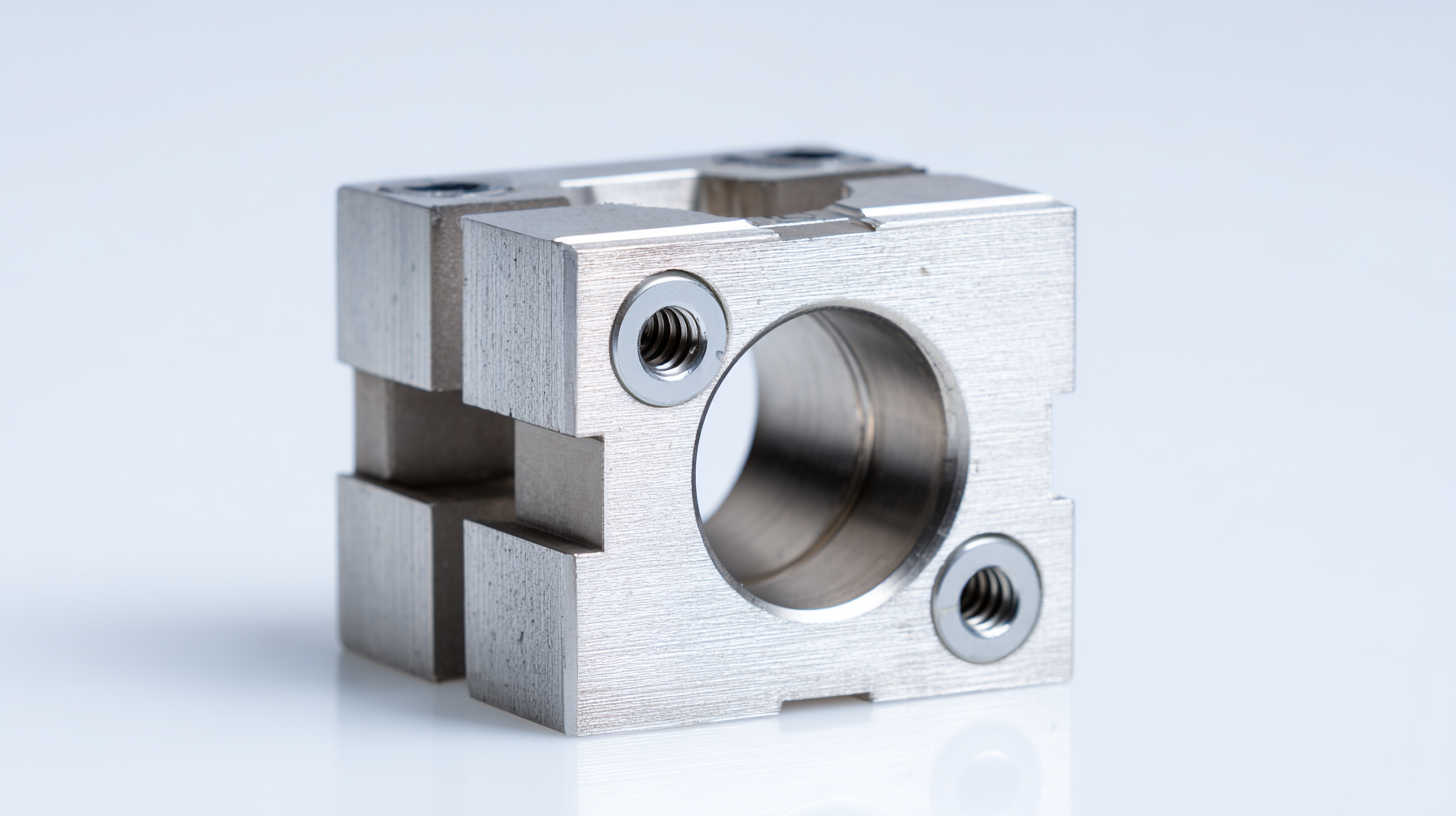

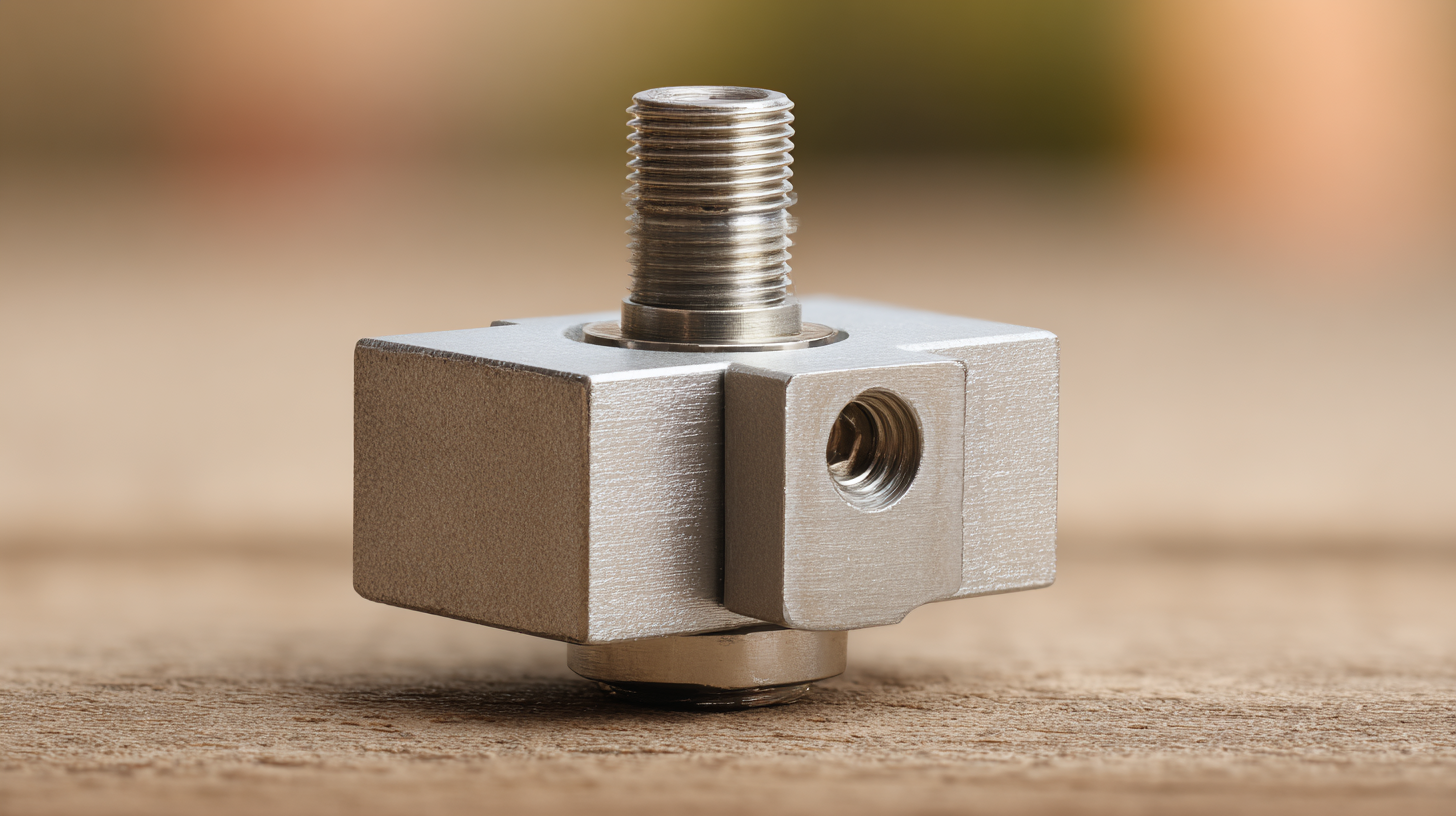

Key Features to Look for in Miniature Load Cells for Optimal Performance

When selecting miniature load cells for optimal performance, there are several key features to consider. First and foremost, load capacity should align with your specific application requirements. It’s crucial to choose a load cell that can handle the maximum expected load without compromising accuracy. For tasks requiring precise measurements, look for high-resolution load cells, as they offer more accurate readings and improve overall reliability.

Another important aspect is the environmental protection rating of the load cell. Ensure that it meets the required standards for dust and moisture resistance, especially if your application is in a challenging environment. Additionally, selecting a load cell with temperature compensation can significantly enhance performance, maintaining accuracy despite fluctuations in operating conditions.

Tips: Keep in mind that the physical design of the load cell can affect its integration into your system. Pay close attention to the size and shape, ensuring compatibility with your equipment. It's also beneficial to consider the material used in the load cell's construction, as this can influence durability and weight. Lastly, always verify the calibration process, as proper calibration is essential for achieving consistent and accurate results.

Innovative Applications of Miniature Load Cells in Various Industries

Miniature load cells are becoming increasingly pivotal across various industries thanks to their compact size and precise measurements. These small yet powerful devices can be found in applications ranging from robotics to medical devices, enabling manufacturers to innovate while maintaining high accuracy. In robotics, miniature load cells provide critical feedback for force and weight detection, allowing robots to perform delicate tasks, such as manipulating fragile objects or maintaining stability in uneven environments.

In the medical field, miniature load cells contribute to the development of advanced healthcare technologies, such as portable diagnostic equipment and surgical instruments. Their ability to deliver accurate weight measurements ensures that devices like infusion pumps function correctly, enhancing patient safety. Furthermore, in the aerospace and automotive industries, these load cells are utilized for quality control and weight management, ensuring that equipment meets stringent safety standards. As technology continues to evolve, the versatility and efficiency of miniature load cells will undoubtedly drive innovation across a myriad of sectors.

Navigating the 2025 Technology Trends in Load Cells

| Application | Industry | Load Capacity (kg) | Precision (%) | Size (mm) |

|---|---|---|---|---|

| Robotics | Manufacturing | 50 | 0.5 | 30 x 20 |

| Weighing Scales | Retail | 20 | 0.2 | 25 x 15 |

| Automated Test Equipment | Electronics | 100 | 0.1 | 40 x 30 |

| Medical Devices | Healthcare | 10 | 0.5 | 20 x 10 |

| Load Monitoring | Construction | 200 | 0.1 | 50 x 40 |

Comparative Analysis of Leading Manufacturers in the Miniature Load Cell Market

In the rapidly evolving landscape of technology, the miniature load cell market has gained substantial traction due to its versatility and precision in various applications. This comparative analysis focuses on leading manufacturers who are at the forefront of innovation in this sector. Notably, brands like HBM, OMEGA Engineering, and Flintec are known for their commitment to quality and technological advancements. Each of these manufacturers offers a unique set of features in their load cells, catering to different industrial needs, from aerospace testing to automotive applications.

In the rapidly evolving landscape of technology, the miniature load cell market has gained substantial traction due to its versatility and precision in various applications. This comparative analysis focuses on leading manufacturers who are at the forefront of innovation in this sector. Notably, brands like HBM, OMEGA Engineering, and Flintec are known for their commitment to quality and technological advancements. Each of these manufacturers offers a unique set of features in their load cells, catering to different industrial needs, from aerospace testing to automotive applications.

When evaluating these manufacturers, several factors come into play, including performance specifications, price range, and customer support. HBM's load cells, for instance, are renowned for their high accuracy and reliability, making them ideal for critical measurement tasks. In contrast, OMEGA provides a broad range of models with customizable options, allowing for greater flexibility in application. Flintec stands out with its robust design suitable for harsh environments, ensuring durability and long-term performance. By analyzing these key players, industry professionals can make informed decisions when selecting the best miniature load cells for their specific requirements.

Future-Proofing Your Projects: How to Choose the Right Load Cell Technology for 2025

As we approach 2025, the landscape of load cell technology is evolving rapidly. Future-proofing your projects is critical, particularly given the anticipated growth in the load cell market, which is projected to reach $1.6 billion by 2026, according to a report by MarketsandMarkets. Advancements in miniature load cells, such as improved accuracy and reduced size, are revolutionizing applications in sectors ranging from medical devices to robotics. Understanding these trends will help ensure your projects meet the demands of tomorrow.

When selecting the right load cell for your application, consider these tips: First, assess the required precision; miniature load cells can offer accuracy levels as high as ±0.1%. Secondly, evaluate the environmental conditions—industrial applications may require load cells with enhanced durability and resistance to harsh conditions. Lastly, consider the integration with digital technologies; many modern load cells now feature IoT connectivity, allowing for real-time monitoring and data analysis.

By carefully choosing load cell technology that aligns with future trends, you can optimize functionality while reducing costs and operational risks. Ensuring compatibility with emerging tech will set the foundation for successful projects in 2025 and beyond.