sales@loadcellsensor.com

sales@loadcellsensor.com

2026 Top Tension Compression Load Cell Trends and Innovations?

The Tension Compression Load Cell industry is evolving rapidly. As of 2023, the market has been valued at over $1 billion. This growth is driven by increasing demand in various sectors, such as medical, aerospace, and industrial automation. Innovations in material science have enhanced load cell performance. Manufacturers are focusing on improving accuracy and durability.

Recent reports highlight significant trends, including wireless technology integration and miniaturization. These advancements allow for better data collection and real-time monitoring. The rise of IoT is triggering shifts in traditional load cell applications. Users expect smarter and more adaptable solutions. The ability to connect load cells to cloud platforms is becoming essential.

However, challenges remain. Competition is fierce, causing some firms to compromise quality for cost. The need for precise calibration and maintenance is often overlooked, leading to performance issues. As the industry moves forward, addressing these concerns will be crucial for sustainable growth. Embracing innovations while ensuring reliability in Tension Compression Load Cells will define the market landscape in 2026.

Emerging Technologies in Tension and Compression Load Cells for 2026

As the demand for precise measurements grows, tension and compression load cells are evolving. In 2026, emerging technologies will reshape this field significantly. One promising direction is the integration of IoT capabilities. This allows real-time data transmission, increasing accuracy and efficiency. With devices connected, users can monitor performance remotely.

Another innovation is the use of advanced materials. These materials enhance durability and sensitivity. For example, smart polymers can change properties under stress, providing more accurate readings. Adjustments in design could also minimize temperature influence on measurements. However, developing these technologies poses challenges. Reliability in harsh environments remains a concern, and early prototypes may show inconsistencies.

Additionally, machine learning algorithms are making waves. They can analyze data patterns, predicting failure points. This predictive maintenance could minimize downtime and costs. Yet, reliance on algorithms may lead to overconfidence in their results. Continuous testing and human oversight are vital to ensure system integrity. Balancing automation with manual checks will be crucial for success in this innovative landscape.

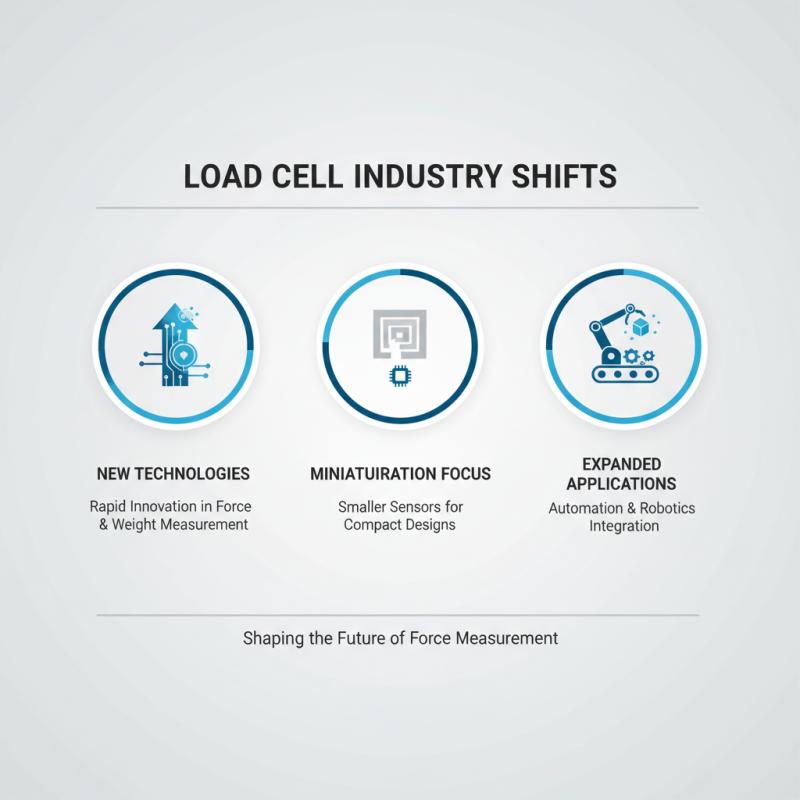

Key Industry Trends Shaping Load Cell Innovations

The load cell industry is experiencing notable shifts. New technologies emerge weekly, shaping how we measure force and weight. Companies are increasingly focusing on miniaturization. Smaller load cells open up possibilities for various applications, especially in automation and robotics.

Another key trend is the integration of IoT. Connecting load cells to the internet allows for real-time data monitoring. However, this innovation also raises concerns about data security. Implementing robust security measures is a challenge that many face.

Sustainability is becoming crucial in load cell design. Manufacturers are exploring eco-friendly materials. While this shift is commendable, the balance between cost and sustainability remains tricky. Companies must navigate these complexities while staying competitive in a fast-evolving market.

Impact of IoT and Smart Technology on Load Cell Design

The integration of IoT and smart technology into load cell design is transformative. Load cells are essential for measuring weight and force. With advancements in IoT, these devices now provide real-time data and remote monitoring capabilities. According to a recent industry report, around 40% of load cells will feature smart technology by 2026.

These new designs enable predictive maintenance. Users can track performance metrics instantly. However, the increased data flow also raises concerns about security. As more devices connect to the internet, the risk for cyber vulnerabilities grows. Industry experts point out that many companies lack adequate protections. This gap challenges manufacturers to innovate securely while embracing smart technology.

One significant trend is the miniaturization of components. Miniature load cells are becoming common, ideal for compact spaces. Still, smaller devices can lead to fragility issues. Striking the right balance between size, durability, and functionality is crucial. In the next few years, companies must address these challenges to stay competitive. The advancements in load cell design show great promise, but they also pose risks requiring careful consideration.

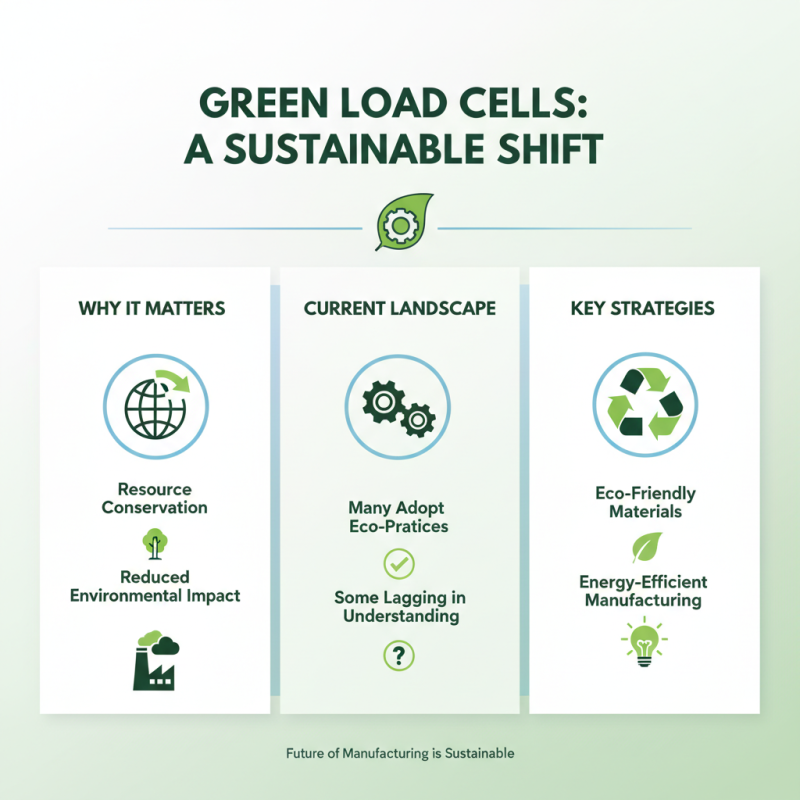

Sustainability Practices in Load Cell Manufacturing

Sustainability is crucial in load cell manufacturing. Many companies start prioritizing eco-friendly practices. This shift can create a significant impact on resource conservation. However, not all manufacturers fully understand its importance. Some strategies are not yet widely adopted.

One approach is reducing energy consumption during production. Solar panels and wind energy are promising options. Yet, implementing these technologies requires upfront investments. Many manufacturers hesitate, fearing increased costs. Moreover, waste reduction is an essential focus. Reusing materials and recycling components can minimize landfill contributions. Still, the awareness of these methods varies among different companies.

Another area is the choice of materials. Biodegradable options and recycled metals are gaining attention. Transitioning to these alternatives, however, poses challenges. Often, the performance requirements for load cells conflict with sustainable choices. Moreover, finding suppliers that prioritize sustainability can be difficult. The industry still grapples with balancing performance and eco-responsibility. This ongoing struggle can lead to innovative solutions, although progress may be slow.

Future Applications of Load Cells Across Various Industries

The future of load cells looks promising as industries explore innovative applications. Manufacturing is evolving. Load cells can monitor weight precisely on assembly lines. This ensures product quality consistently. It also reduces wastage. Automation in factories relies heavily on accurate measurements.

In healthcare, load cells are vital. They enhance patient monitoring systems. Weight management becomes seamless, improving the overall care experience. Hospitals can utilize them for better equipment management. Adjusting treatments based on real-time data is crucial.

Yet, there are challenges to consider. Integrating load cells with existing systems can be complex. Data management requires careful planning. Not every application yields perfect results. Continuous improvement is essential. Learning from failures can lead to better implementations. Embracing innovation means being ready to adapt.

2026 Top Tension Compression Load Cell Trends and Innovations

| Industry | Application | Load Cell Type | Trend/Innovation | Future Prospects |

|---|---|---|---|---|

| Manufacturing | Automated Quality Control | Digital Load Cells | Real-time Data Analysis | Increased Efficiency |

| Healthcare | Patient Monitoring | Miniature Load Cells | Enhanced Sensitivity | Personalized Medicine |

| Agriculture | Crop Load Monitoring | High-Capacity Load Cells | IoT Integration | Smart Farming |

| Construction | Structural Health Monitoring | Wireless Load Cells | Remote Monitoring | Safety Improvements |

| Logistics | Weight Verification | Load Pin Load Cells | Automation Integration | Streamlined Operations |

Related Posts

-

Exploring Alternative Load Cell Solutions for Optimizing Tensile and Compressive Testing

-

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements

-

Unlocking Industry Potential with Strain Gauge Load Cells at the 2025 China Import and Export Fair

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide

-

Common Issues Faced When Using Best Small Load Cells