sales@loadcellsensor.com

sales@loadcellsensor.com

Solutions for Accurate Measurement with Micro Load Cells

In the realm of precision measurement, Micro Load Cells have emerged as essential tools for applications requiring accurate force and weight measurements at minimal loads. These compact devices, known for their remarkable sensitivity and reliability, are widely utilized in various industries, from medical equipment to robotics, where space and accuracy are critical. This tutorial explores the various solutions for leveraging Micro Load Cells effectively, ensuring optimal performance in your measurement processes. By understanding the intricacies of these small yet powerful sensors, you can enhance your data collection capabilities and improve overall system efficiency. Join us as we delve into the practical applications, selection criteria, and installation techniques necessary to harness the full potential of Micro Load Cells in your projects.

Understanding Micro Load Cells: Principles of Accurate Measurement

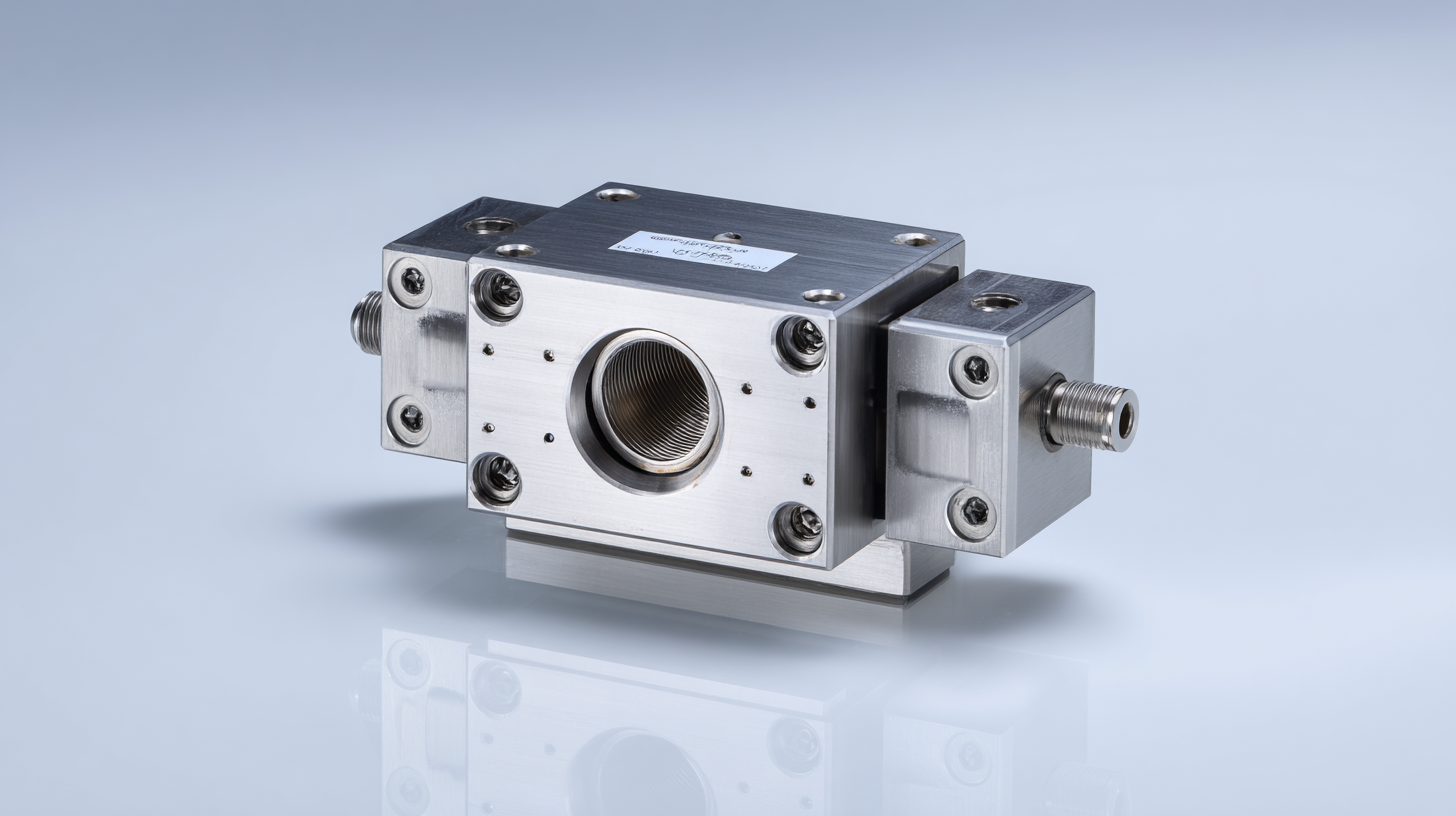

Micro load cells are essential devices for precise measurement in various applications, ranging from industrial automation to medical devices. Understanding the principles behind these small yet powerful components is critical for engineers and researchers aiming for accuracy in their measurements. At the heart of micro load cells lies the technology of strain gauges, which convert mechanical strain into an electrical signal. When a force is applied, the material deforms slightly, and the strain gauge detects this change, allowing for precise measurement of the load.

The design and calibration of micro load cells play a crucial role in their effectiveness. Factors such as temperature stability, hysteresis, and linearity must be carefully managed to ensure reliability. Modern advancements have led to the development of more sensitive and compact load cells, offering enhanced performance without compromising on accuracy. By employing specific materials and advanced manufacturing techniques, manufacturers can produce micro load cells that exhibit minimal drift and high resolution, making them suitable for applications where precision is paramount. Understanding these principles empowers users to select the right micro load cell for their specific needs, ensuring optimal performance in their measurement tasks.

Key Factors Affecting Accuracy in Micro Load Cell Applications

When working with micro load cells, several key factors can significantly affect their measurement accuracy. First, environmental conditions play a crucial role; temperature fluctuations and humidity can introduce measurement errors. It’s essential to maintain a stable environment or use compensation methods to mitigate these effects. For instance, consider investing in temperature-controlled settings or calibration tools to ensure consistent performance.

Another factor is the mechanical setup. Proper alignment and support for the load cell are critical to preventing off-axis loads that can skew results. **Misalignment** can lead to significant discrepancies, so ensure your installation allows for precise loading. Regularly check the mounting and support structures to maintain the integrity of the measurement process.

Tips: Always calibrate your load cell after installation and periodically thereafter. Additionally, use shielding and grounding techniques to reduce electrical noise, which can interfere with the signal. Be mindful of the load cell's capacity; operating close to its limits can compromise accuracy, so it's wise to select a cell rated for your application's requirements.

Best Calibration Techniques for Enhanced Measurement Precision

In the realm of measurement precision, the importance of employing advanced calibration techniques cannot be overstated. Calibration serves as a cornerstone for micro load cells, ensuring their accuracy and reliability in various applications. Techniques such as comparison with reference standards, automated calibration systems, and digital signal processing play a crucial role in minimizing errors and enhancing the overall performance of these tiny sensors. By meticulously calibrating micro load cells, industries can achieve more reliable data, facilitating better decision-making processes.

Recent advancements in technology, such as the development of the microminiature silicon-based optical gyroscope, highlight the continuous evolution in precise measurement tools. This innovation demonstrates how overcoming challenges like noise interference can significantly improve measurement reliability. Similarly, as industries increasingly focus on integrating cutting-edge technologies like quantum sensing and metrology, the need for precise calibration methods becomes even more apparent. With techniques designed to enhance measurement precision, businesses can leverage smaller and more effective measurement devices to achieve unprecedented levels of accuracy in their operations.

Solutions for Accurate Measurement with Micro Load Cells - Best Calibration Techniques for Enhanced Measurement Precision

| Measurement Technique | Calibration Method | Typical Accuracy (%) | Application Areas |

|---|---|---|---|

| Static Load Measurement | Deadweight Calibration | 0.01 - 0.1 | Material Testing, Weighing Systems |

| Dynamic Load Measurement | Dynamic Calibration Through Simulation | 0.5 - 1.0 | Industrial Equipment, Robotics |

| Tension Measurement | Sine Wave Calibration | 0.1 - 0.5 | Cable Tension Monitoring, Aerospace |

| Compression Measurement | Multi-Point Calibration | 0.1 - 0.3 | Construction, Civil Engineering |

| Weighing Scale Calibration | Offset Calibration | 0.05 - 0.15 | Retail, Logistics |

Common Challenges and Solutions in Micro Load Cell Usage

Micro load cells are essential in various applications ranging from industrial scales to high-precision measurements in laboratory settings. However, users often encounter challenges that can lead to inaccurate readings. One common issue is mechanical misalignment, which can occur during installation or mounting. This misalignment can significantly affect the load cell’s performance, resulting in errors in measurement.

To mitigate this, always ensure proper alignment during installation. Consider using alignment fixtures or performing regular calibrations. Additionally, be cautious about environmental factors such as temperature and humidity, as these can also distort readings.

Humidity can lead to corrosion, affecting the sensor's integrity over time. To prevent this, consider encasing your load cells in protective housing or using hermetically sealed models designed for harsh environments.

Another challenge is achieving consistent readings in dynamic applications. Load cells may respond differently under varying speeds of load application. To improve accuracy, implement a data acquisition system capable of filtering out noise and averaging the readings over time. Always conduct thorough testing under real-world conditions to ensure reliability.

Innovative Technologies Transforming Micro Load Cell Performance

The advancements in micro load cell technology are not just about improving precision; they are also reshaping how industries approach measurement applications. Innovative solutions, such as integrating artificial intelligence and machine learning into sensor systems, are driving performance to new heights. For instance, research indicates that incorporating these technologies can boost accuracy by up to 30% in various applications, ranging from manufacturing to environmental monitoring.

Tips: When selecting a micro load cell, consider the operational environment and specific requirements. Ensure the chosen load cell can handle the expected load range while providing accurate readings at minimal power consumption. This is not just about immediate benefits; improved efficiency can lead to long-term savings and reliability.

Moreover, the transition to smart, data-driven systems has also prompted a paradigm shift. By utilizing real-time data analytics and cloud connectivity, businesses can enhance their load measurement processes. According to recent studies, companies adopting smart sensors report a 25% increase in operational efficiency. As we embrace these innovative technologies in micro load cells, we can expect continued transformations in their performance and applicability across various sectors.

Solutions for Accurate Measurement with Micro Load Cells

This chart presents a comparison of the performance metrics of various micro load cell technologies in terms of accuracy and sensitivity.