sales@loadcellsensor.com

sales@loadcellsensor.com

Identifying Key Issues in Bending Beam Load Cell Usage and Their Impact on Accuracy

In the realm of precision measurement, Bending Beam Load Cells serve as essential components in various industrial applications, providing reliable data for weight and force measurement. However, their efficacy is often compromised by a range of key issues that can significantly impact their accuracy. Understanding these challenges is crucial for engineers and technicians who rely on these devices for critical measurements. This blog aims to explore the common problems associated with Bending Beam Load Cell usage, including environmental factors, installation techniques, and calibration processes, while also offering practical solutions to enhance performance and reliability. By addressing these issues, we can ensure that Bending Beam Load Cells deliver optimal results, thus maintaining the integrity of measurement systems across various sectors.

Common Misconceptions About Bending Beam Load Cells and Their Effects on Measurements

Bending beam load cells are essential components in many weighing applications, yet several misconceptions about their usage persist. One common belief is that these load cells are inherently more accurate than other types of load cells. While bending beam load cells offer high precision, their accuracy can be significantly affected by installation conditions, environmental factors, and the specific load configuration. Misunderstanding the operational parameters can lead to improper calibration and ultimately flawed readings.

Another prevalent myth is that any bending beam load cell can function effectively across a wide range of weights without careful selection. In reality, each load cell has an optimal range for which it is designed. Exceeding this range can not only distort measurements but also damage the load cell. Ignoring these critical specifications can result in significant errors in data, which may have dire consequences in sensitive applications like laboratory weighing or industrial processes. Understanding these issues is crucial for users aiming to achieve accurate and reliable measurements in their applications.

Understanding Load Cell Performance: Key Factors Influencing Accuracy in Bending Beam Design

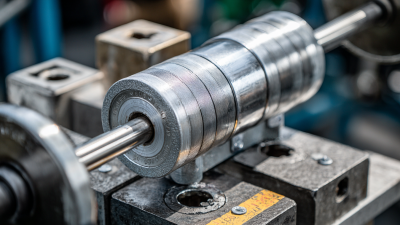

Bending beam load cells are widely utilized for their sensitivity and accuracy in measuring force and weight. However, their performance can be significantly influenced by several key factors, particularly the design of the bending beam itself. The geometry of the beam, including the beam’s dimensions and the angle of the bending, plays an essential role in how accurately the load cell can register the applied force. Understanding these factors is crucial for optimizing load cell performance.

Recent studies on structures such as the optimization of proton exchange membrane fuel cell flow channels and stress-strain curve analysis in TPMS structures reaffirm the importance of meticulous design in achieving desired mechanical properties. For instance, the geometric features in the design of channel structures can affect fluid dynamics and, subsequently, overall system efficiency. Likewise, in load cell applications, maintaining dimensional accuracy and understanding deformation behavior under load can greatly enhance measurement reliability. Employing advanced methods, including finite element analysis and machine learning, can facilitate the identification of potential improvements in load cell design, leading to increased accuracy in measurements and better overall performance in various industrial applications.

Environmental Conditions: How Temperature and Humidity Impact Load Cell Readings

Load cells are essential components in various industrial applications, and their accuracy can be significantly affected by environmental conditions such as temperature and humidity. According to a report by the National Institute of Standards and Technology (NIST), deviations in temperature can lead to errors in load cell readings by as much as 0.02% per degree Celsius. This means that in environments with fluctuating temperatures, even a small change can result in substantial inaccuracies, particularly in precision-dependent industries like pharmaceuticals and food processing.

Humidity also plays a critical role in the performance of bending beam load cells. A study published by the International Journal of Measurement Technologies indicates that high humidity levels can lead to condensation on the sensor components, which can impair the electrical conductivity and overall functionality of the load cell. The study found that relative humidity nearing 90% resulted in a reading drift of approximately 0.05% per hour. Such variations can compromise the integrity of weighing processes, highlighting the need for thorough environmental monitoring to maintain optimal load cell performance.

Routine Maintenance Practices for Ensuring Reliable Performance of Bending Beam Load Cells

Routine maintenance is crucial for ensuring the reliability and accuracy of bending beam load cells, as even minor issues can significantly affect their performance. Regular inspection should include checking for signs of wear, corrosion, and any physical damage that could interfere with the load cell's operation. It's essential to ensure that the load cell is correctly calibrated and functioning within its specified range. Implementing a schedule for routine calibrations can help identify discrepancies early on and prevent inaccurate measurements that can arise from drift or environmental changes.

Another critical maintenance practice is ensuring that the load cell is properly installed and shielded from external forces that could lead to erroneous readings. This includes checking the mounting conditions and ensuring that the load cell is free from vibrations and other disturbances. Periodic cleaning of the load cell and its surroundings can also minimize the risk of debris accumulation, which can compromise its accuracy. By committing to these routine maintenance practices, operators can significantly enhance the longevity and reliability of bending beam load cells, ultimately leading to more consistent and accurate measurements in various applications.

Troubleshooting Common Issues: Enhancing Accuracy in Bending Beam Load Cell Applications

In the realm of bending beam load cells, achieving high accuracy is paramount. However, common issues can significantly impact performance. One prevalent problem is deflection irregularities caused by non-uniform properties in the materials used, which can yield misleading readings. To troubleshoot this, it is essential to conduct thorough inspections of the load cell structure, ensuring that any irregularities are accounted for. In some cases, integrating advanced materials that enhance linear and nonlinear responses can bolster the overall accuracy of measurements.

Furthermore, it is crucial to consider environmental factors that may affect the load cell's functionality. Temperature fluctuations and moisture levels can alter the characteristics of the material, leading to unexpected errors. By employing rigorous calibration techniques and understanding the principles of material science, users can mitigate these issues effectively. Regular maintenance and adherence to operational guidelines also play a critical role in sustaining the accuracy of bending beam load cells, ensuring that they perform optimally in various applications.

Identifying Key Issues in Bending Beam Load Cell Usage and Their Impact on Accuracy

| Issue | Description | Impact on Accuracy | Potential Solutions |

|---|---|---|---|

| Temperature Variations | Fluctuations in temperature can affect the material properties of the load cell. | Can lead to drift in measurements, reducing accuracy. | Implement temperature compensation techniques. |

| Mechanical Stress | Overloading or uneven loading can result in permanent deformation. | May cause permanent changes in output, reducing repeatability. | Use overload protection devices or sensors. |

| Electrical Interference | Surrounding electrical devices can induce noise in the signal. | Can produce inaccurate readings. | Employ shielded cables and proper grounding techniques. |

| Installation Errors | Poor alignment or incorrect mounting can lead to measurement errors. | Can result in bias in the measurements. | Follow precise installation guidelines and use alignment tools. |

| Calibration Issues | Improper calibration can lead to systematic errors. | Results in inaccurate measurement data. | Ensure regular calibration with standardized weights. |

Related Posts

-

Exploring the Future of Load Cells: Innovations Beyond the Best Bending Beam by 2025

-

Unlocking Precision: Essential Tips for Choosing the Right Ring Load Cell for Your Needs

-

Exploring the Use of Thin Load Cells in Heavy Machinery and Challenges Faced in Precision Measurements

-

Advantages of Utilizing Ring Load Cells for Precise Industrial Measurements

-

Top 10 Micro Load Cell Manufacturers from China at the 137th Canton Fair

-

Common Issues Faced When Using Best Small Load Cells