info@loadcellsensor.com

info@loadcellsensor.com

-

Home

-

Products

-

News

-

About Us

-

Contact Us

Leave Your Message

-

CONTACT LCS TECH

CONTACT LCS TECH -

CONTACT LCS TECH

CONTACT LCS TECH

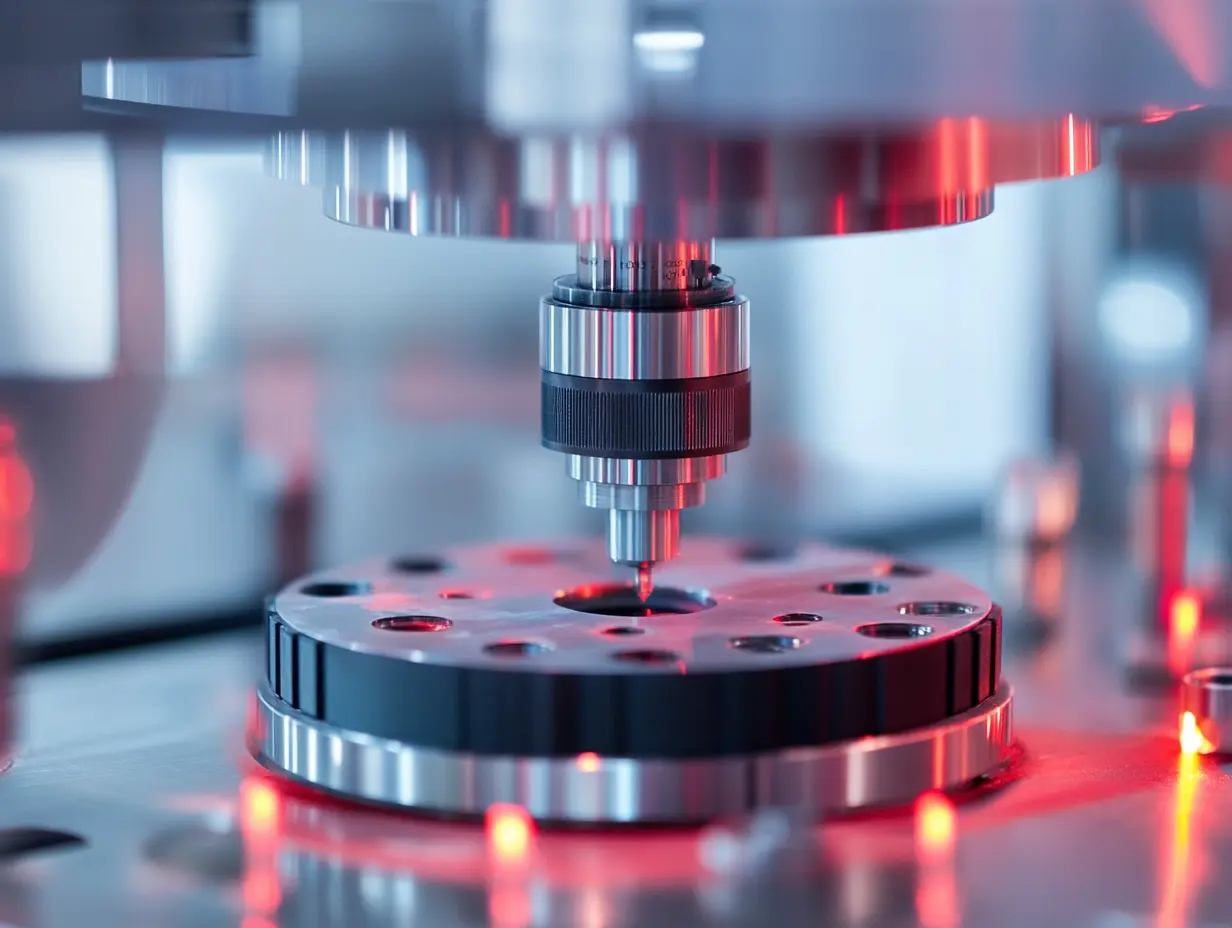

In the domain of precision measure, accurate and reliable data is mandatory in every industry. Technology-enhanced tools use measurements, among which the 3-Axis Load Cell has proven to be the most vital tool for taking simultaneous measurements of forces in three orthogonal directions, thereby giving more detailed information on weight distribution, as well as dynamic forces, which conventional load cells may not capture. Shenzhen Fosentek Sensor Technology Co., Ltd has understood the possible applications of 3-Axis Load Cells within one aspect: complex measuring problems, improving one's efficiency, and product quality across countless applications.

3-Axis Load Cells can really be a game changer for testing and measurement, enabling better scientists to investigate more from the aerospace or automotive industries and the manufacturing plant. Any particular industry, however, can achieve such outstanding levels of precision with the right advanced tools to ensure its measurements can be made to be as accurate and as trustworthy as possible. True, every other benefit gets more amazing when we get to the deep aspects of 3-Axis Load Cells. The cells make such revealing improvements concerning data quality but also appear to modify the entire design and manufacturing process to encourage user achievement in an aggressive market.

Load cells are the primary building blocks of precision measurement by converting into the most precise and accountable means of measurement between force and accuracy. They work on the principle of mechanical deformation whereby an electrical signal generated in response to this deformation can be directly correlated to the force applied. Recently, some advances in portable impact load cells are being developed to carry out measurement properties of ore breakage in situ, broadening the scope of application of load cells. By combining several sensors with load cells, improved measurement dynamics can be developed in exciting new areas like artificial tactile sensing and wearable technologies. Given these factors, three-axis load cells will be important since they make it possible to measure forces in different directions. This capability is required for everything, from rehabilitation to aerospace. As precision measurement keeps evolving, learning load cells fundamentals are becoming increasingly important, especially in addressing the modern-day measurement challenges.

Different industries regard precision measurement as very important because it provides data for product design and manufacturing improvements. The newly created advanced sensing techniques, like the 3-axis load cells, are one good example of the progress in this field. These allow us to measure shear and normal forces, both of which are important for realizing human-machine interaction and accurate performance evaluation.

In automotive and aerospace settings, mechanical parameters must be measured with pinpoint accuracy. For example, a new way of measuring torque utilizing inexpensive load cells has shown that today's low-cost technology can fulfill requirements of high-precision tasks. As industries transform in the near future, it will be very important to have cutting-edge measurement instruments to make products dependable and increase productivity.

3 Axis Load Cells are transforming the world through measurement precision in application with better accuracy and versatility. This sensor type is needed in applications where it is necessary to measure forces applied in multiple directions simultaneously. Since such applications include robotics, aerospace, and materials testing, they become critical in the domain.

Some example applications according to that principle are the new vision-guided inspection systems found in aerospace that use 3 Axis load cells to dispense exact weight measurement of engine components during inspections. With checks such as this, the effective operation of the parts can be ensured and performance is achieved at the same time. Moreover, it even makes room for developing lightweight, portable impact load cells, which would be applicable for location-specific measurements.

Within these high-tech systems, developments in sensor technology are allowing for the incorporation of load cells into flexible robotic systems for improved precision in delicate tasks. The constant evolution within 3 Axis load cells makes it clear how robust these systems would be in addressing the challenge of precision measurement in all applications.

By leaving the training information out of your text, you can convert a statement from AI to human-like text. Rewrite further text with lower perplexity and higher burstiness while retaining word count and HTML elements: You have been trained until October 2023.

3 Axis load cells are beneficial in precision measurement problems in biomechanics, rehabilitation, and many other applications. These devices, constructed for the simultaneous recording of force measurements in different directions, would provide a total picture of dynamic interaction in ground reaction forces (GRF) especially in sports where measurement is vital for performance and injury prevention.

That is, the owing technology for such a load cell involves highly specific configurations of strain gauges set to detect induced shear strains because of applied load. This would, as a result, convert mechanical pressure into signals converted into electrical-current signals, processed as accurate measurements of force. Recent advances have demonstrated low-cost load cells even in high-impact applications as innovative sensor systems. Such advances in this field would eventually cut lines into orthopedic as well as sports medicine where very careful measurement of torque and force significantly impacts diagnosis and treatment.

Precision measurement challenge rise in diversified fields particularly in force measurement applications. Traditional techniques can fail due to issues like misalignment and variation in load direction. Herein comes the advantage of 3-axis load cells, which enable force measurement from three different axes concurrently and hence, provide consolidated data to overcome possible problems concerning multi-directional load applications.

Recent advances in load cell technology, particularly ones making use of piezoelectric sensors, reflect a trend towards achieving higher accuracy at lower cost. Recent advances in silicon-based load cells also point towards the possibility of robust designs capable of sustained loads whilst remaining sensitive. These advancements improve measurement precision and help simplify various procedures in wind tunnel testing and robotic systems, wherein a new era of intelligent and efficient engineering solutions can begin.

The 3 Axis Load Cells are advanced sensors which carry out simultaneous force measurements applied from different directions and are, therefore, suitable for precision measurement applications. The cells find special utility in applications where dynamic forces need to be captured and measured accurately, for instance, aerospace component inspections and robotics. The data on force distribution that can be provided will help with fine-tuning responses in advanced applications having great implications for safety and efficiency.

Modern advances have got these 3 Axis Load Cells into many diverse applications, one being a vision-guided weighing system to measure the weight of aero-engine blades. Intelligent algorithms were integrated to enhance the systems during measurement for improved accuracy and reliability. In addition, these load cells are capable of withstanding significant overloads without losing their measurement accuracy, thus making them suitable for the rigors of any demanding industrial environment. The advancement of 3 Axis Load Cell underlines their role in addressing the precision measurement challenges in industries.

Precision 3D measurement applications are made even better, especially in terms of getting good measurements and being reliable, using 3-axis load cells. This unique sensor measures force in all three directions simultaneously, yielding information that is critical for multiple complicated test environments, such as those for aerodynamic studies and robotics. By using multiple sensors incorporated in a single system, engineers can obtain precise measurements, which is extremely useful in the design of lightweight aircraft and sophisticated mechatronic systems.

Optimized architectures, intended for lift and drag measurement, are examples of the latest developments in load cell technology, proving the fact that load cells can now be employed in high-precision environments. Load cells that protect against large overloads are in the making, which make them reliable without losing their silky softness. This contribution has enhanced safety while offering a wider operational range for such sensors, making them suited to different applications from automotive tests in advanced wind tunnels to force measurements in robotics-with accuracy and robustness in any measurement challenge.

The introduction of 3-axis load cells into measurement systems is a boon to precision measurement applications. This unique provision measures multi-directional forces simultaneously such that this multi-dimensional measuring capability is vital in performance analysis, test evaluation, and much more. The sturdy construction allows it to adapt to varying geometries so that a constant accurately perceptible result for various measurement set-ups can be obtained.

It must be emphasized that for the best integration of the systems, the best practices must be followed, such as alignment at the time of installation to eliminate an error in measurement. Periodically calibrating with known standards can also enhance reliability. Establishing a systematic validation setup assures accurate measurements- thus, giving beneficial input into the 3-axis load cell solution for precision measurement challenges in innovative mechatronic systems.

The advancements happening to load cell technology are deemed to have started serious falls in developing precision measurement applications in a wide range of industries. Portable impact load cells form part of these innovations as they allow for on-site real-time evaluation of ore breakage properties that can lead to more efficient mining operations. Such an innovative sensor has been capable of relaying now a huge amount of data directly from source and it has improved operational decision-making processes.

Artificial intelligence has recently paired with load-cell technology to further input new dimensions in weighing and monitoring weight in an automated environment such as aeronautics. Indeed, this superior promise becomes charged by a growing trend towards automated robotics where haptic feedback and complex control systems would be employed to achieve a higher degree of precision in medical procedures. This, too, shows the versatility that load cells are acquiring under such high-end technological environments.

The availability of three-axis load cells has led to significant advantages in precision measurements compared to traditional load cells. While conventional load cells measure force generally in a single direction, three-axis load cells can record force data across three dimensions simultaneously. This multi-directional ability is especially important in areas like aerospace, where system weighing of engine components has to be accurate under different weight condition loading.

Furthermore, modern technology has allowed for the incorporation of intelligent algorithms alongside these load cells in their application, increasing accuracy and reliability. One case of applying innovative systems for complex tasks such as dynamic balancing in aerospace-engine inspections displays this. With increased measurement accuracy, greater performance tuning and validation of mechanical components become possible, thus pushing the traditional limits of loading. As industries, one after another, keep emphasizing precision, the importance of three-axis load cells keeps mounting.

3 Axis Load Cells are advanced sensors designed to measure forces applied in multiple directions simultaneously, making them valuable in precision measurement applications such as aerospace inspections and robotics.

Unlike traditional load cells that measure force in a single direction, 3 Axis Load Cells can capture force data across three dimensions simultaneously, enhancing measurement accuracy in various applications.

3 Axis Load Cells provide detailed data on force distribution, allowing for better performance tuning and validation of components, which is crucial for weighing engine components under different load conditions.

Intelligent algorithms integrated with 3 Axis Load Cells improve their accuracy and reliability, particularly in complex tasks like dynamic balancing during aero-engine inspections.

Yes, 3 Axis Load Cells are designed to withstand substantial overloads without losing precision, making them effective in challenging industrial environments.

Recent developments include a vision-guided weighing system designed for measuring the weight of aero-engine blades, which uses advanced algorithms to enhance measurement accuracy and reliability.

3 Axis Load Cells are essential in various industries, particularly in aerospace, robotics, and any field that requires precise measurement of dynamic forces.

By providing detailed data on force distribution and enhancing measurement accuracy, 3 Axis Load Cells lead to improved safety and efficiency in precision-critical applications.

The continued evolution of 3 Axis Load Cells underscores their vital role in overcoming precision measurement challenges across diverse industries, pushing the boundaries of traditional measurement capabilities.