sales@loadcellsensor.com

sales@loadcellsensor.com

Advantages of Utilizing Ring Load Cells for Precise Industrial Measurements

In the realm of industrial measurements, the need for precision and reliability is paramount. According to a recent report by Research and Markets, the global load cell market is expected to reach USD 2.5 billion by 2025, driven by the growing demand for accurate weighing and force measurement solutions across various sectors. Among the various types of load cells available, the Ring Load Cell stands out due to its unique design and high performance. Designed to measure tensile and compressive loads with an impressive accuracy level of up to ±0.01%, Ring Load Cells are particularly advantageous in applications that require a compact installation, such as material testing, force measurement, and structural health monitoring. These cells not only contribute to enhanced measurement precision but also facilitate the integration of advanced automation technologies in industrial environments, ultimately leading to increased operational efficiency and safety.

Key Features of Ring Load Cells That Enhance Measurement Accuracy

Ring load cells are a vital tool in industrial settings, offering several key features that significantly enhance measurement accuracy. One of the standout characteristics of ring load cells is their unique design, which provides a robust and stable structure for weighing applications. This configuration helps in distributing the load evenly, minimizing stress concentrations that could lead to measurement errors. Additionally, their compact size allows for easy integration into various machinery, ensuring that precision is maintained without compromising on space.

Another crucial feature is the use of advanced materials and technology in the construction of ring load cells. Many models are designed with high-quality stainless steel, which not only guarantees durability but also resistance to environmental factors like moisture and temperature changes. This ensures that their performance remains consistent even in demanding industrial environments. Moreover, innovative sensing technologies, such as strain gauge technology, enhance their sensitivity, enabling accurate readings even with minimal load variations.

The calibration capabilities of ring load cells further contribute to their accuracy. These devices can be easily calibrated to meet industry standards, ensuring that measurements are reliable over time. This adaptability makes them suitable for a variety of applications, from weighing large machinery components to precise ingredient measurements in manufacturing processes. With such features, ring load cells stand out as an essential choice for industries that prioritize accuracy in their measurement systems.

Comparative Advantages of Ring Load Cells Over Traditional Load Cells

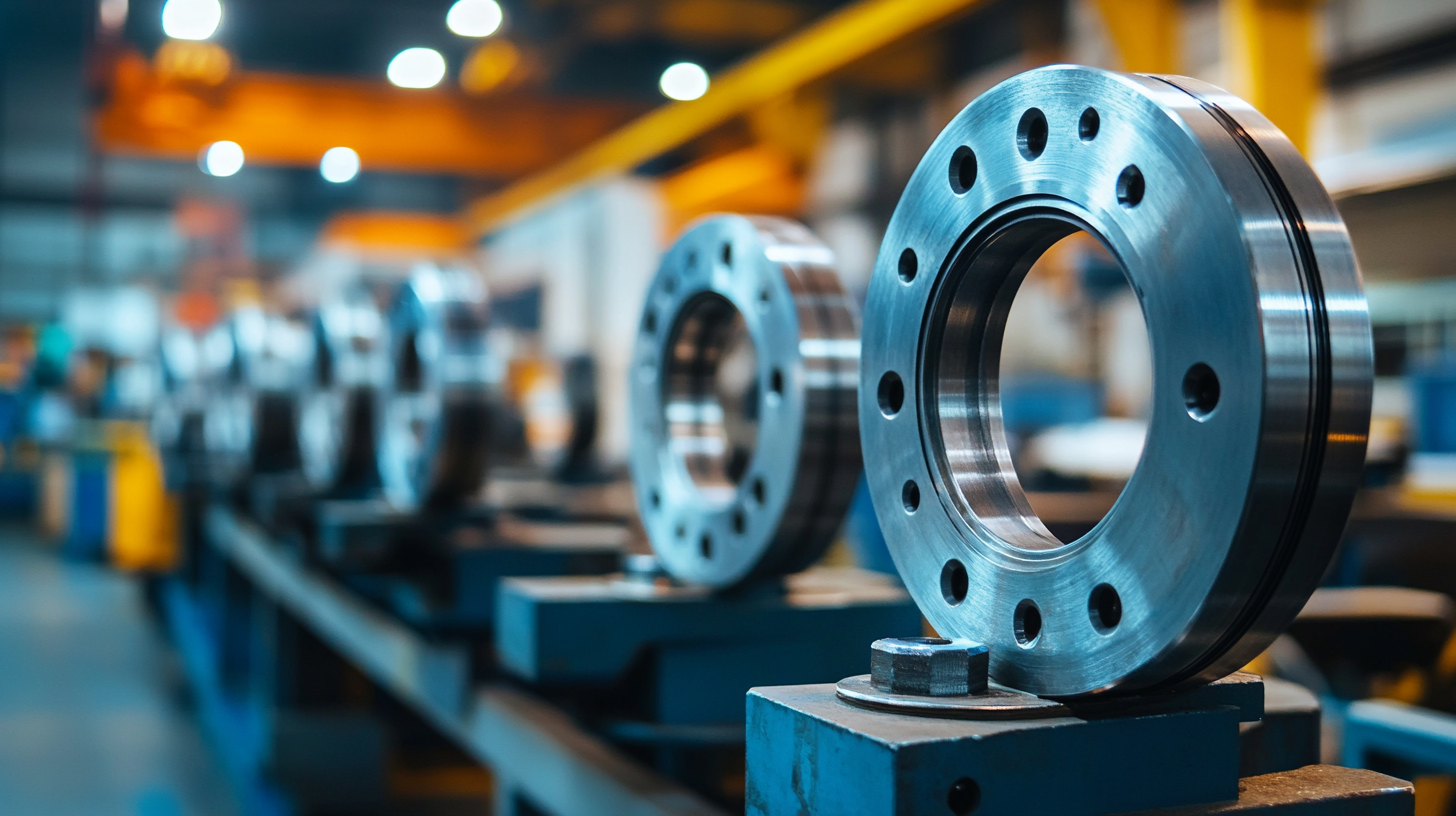

Ring load cells have emerged as a superior choice in industrial measurement applications, particularly when compared to traditional load cells. One of the primary advantages lies in their design, which allows for superior accuracy in weight readings. The ring shape minimizes the effects of off-center loading, ensuring that measurements remain precise even under varying load distributions. This is particularly beneficial in dynamic environments where loads may shift unexpectedly, allowing industries to maintain high standards of quality control.

Additionally, ring load cells excel in their ability to handle large loads while preserving a compact footprint. This characteristic is especially advantageous in space-constrained environments where traditional load cells might struggle. The robust construction of ring load cells also contributes to their long-term durability, providing consistent performance over time. As industries increasingly seek reliable and resilient measurement solutions to optimize operations, the adoption of ring load cells over traditional counterparts is on the rise, ensuring that businesses can conduct their activities with confidence and precision.

Applications of Ring Load Cells in Various Industries

Ring load cells are increasingly becoming the go-to solution for precise measurements across various industries, owing to their unique design and functionality. The manufacturing sector is one prominent area where these load cells excel. According to a report by MarketsandMarkets, the global load cell market is expected to reach USD 1.59 billion by 2024, driven by the growing demand for precise measurement in manufacturing processes. Ring load cells are particularly valued for their ability to measure tensile and compressive forces accurately, making them ideal for applications such as weighing materials and monitoring machine loads.

In the field of construction, ring load cells facilitate accurate weighing of heavy machinery and materials, ensuring safety and compliance with industry standards. A study from Technavio highlights that the construction industry is projected to grow significantly, leading to an increased need for reliable measurement technologies. Ring load cells help mitigate risks by providing real-time data on loads, helping prevent overloading and structural failures.

Another significant application is in the aerospace industry, where precision and reliability are paramount. The International Journal of Aerospace Engineering points out that the demand for accurate load measurement instruments is critical for aircraft testing. Ring load cells offer the precision necessary for weight distribution measurements during aircraft assembly, aiding in compliance with safety regulations and enhancing operational efficiency.

Factors Influencing the Performance of Ring Load Cells

When it comes to precise industrial measurements, ring load cells offer a unique advantage, but their performance can be influenced by several key factors. One of the most critical aspects is the design and construction of the load cell itself. High-quality materials and robust engineering are essential to ensure accurate readings, particularly under varying loads and environmental conditions. The geometry of the ring load cell plays a significant role in distributing stress, which directly affects measurement precision. Manufacturers who pay close attention to these design details can produce load cells that deliver more reliable data.

Another important factor is the installation and alignment of ring load cells. Proper setup is crucial; misalignment can lead to erroneous readings and compromised performance. Careful attention should be given to ensure that the load cell is positioned correctly in relation to the load being measured. Additionally, environmental factors such as temperature fluctuations, humidity, and external vibrations can also affect load cell performance. Implementing effective shielding or stabilization measures can help mitigate these influences, thereby enhancing the accuracy and reliability of the measurements taken.

Advantages of Utilizing Ring Load Cells for Precise Industrial Measurements

This chart illustrates the key advantages of utilizing ring load cells in industrial settings, highlighting factors such as Accuracy, Stability, and Temperature Compensation. Each factor is rated on a scale of 1 to 10, based on performance metrics.

Maintenance Tips for Ensuring Longevity of Ring Load Cells

When it comes to maintaining the longevity of ring load cells, regular inspection and proactive maintenance are crucial. According to a report by the International Society for Automation (ISA), nearly 30% of load cell failures can be traced back to inadequate maintenance practices. To mitigate this risk, users should conduct routine checks to ensure the load cells are free from dust, corrosion, and mechanical wear. Implementing a maintenance schedule that includes bi-annual inspections can significantly enhance the operational lifespan of these critical measurement devices.

Furthermore, calibration is a vital aspect that should not be overlooked. The National Institute of Standards and Technology (NIST) emphasizes that accurate calibration of load cells can prevent discrepancies that may lead to process inefficiencies. Regular calibration sessions help in identifying any drift in measurements early on, allowing for prompt corrections. Alongside functional testing, utilizing protective enclosures can help safeguard ring load cells from environmental factors that frequently contribute to performance degradation. Employing these maintenance tips can ensure that ring load cells operate effectively over time, providing reliable and precise measurements essential for industrial applications.