sales@loadcellsensor.com

sales@loadcellsensor.com

Top 10 Benefits of Using a 1kg Load Cell in Your Projects?

In the world of measurement and automation, the 1kg Load Cell stands out as a vital component. It is widely used in various industries, from manufacturing to research. According to a market report by Research and Markets, the load cell market is expected to grow significantly, driven by increasing demand for accurate measurement tools.

Utilizing a 1kg Load Cell can enhance the precision and reliability of your projects. Many engineering professionals see it as an indispensable tool. For example, in robotics, it can precisely measure weight, offering meaningful data for performance optimization. However, not all projects require a 1kg Load Cell. Understanding when and how to use it is crucial. Misapplication can lead to inaccurate readings and project setbacks.

Moreover, while the benefits are clear, there are some challenges. The calibration process can be intricate, requiring careful attention. If not done correctly, results may vary. This calls for a critical examination of both the implementation and the environment in which the load cell operates. Embracing the complexities of deploying a 1kg Load Cell can lead to improved outcomes in various applications.

Understanding Load Cells and Their Functionality

Load cells play a crucial role in various applications. At their core, load cells convert force or weight into measurable electrical signals. This functionality makes them essential for many industries, including manufacturing, automotive, and medical. A 1kg load cell, for example, is ideal for projects requiring precise measurements. Their compact size allows for easy integration into various systems.

Understanding load cells involves grasping how they operate. Typically, they use strain gauges to measure deformation when weight is applied. This transformation results in changes in electrical resistance, which can be quantified. The accuracy of this process is vital. It’s important to ensure the load cell is correctly calibrated to avoid errors in measurements. Calibration can be a tricky process. Mistakes here can lead to inaccurate data, which can affect the entire project.

In practical applications, using a 1kg load cell can greatly enhance the reliability of a project. Whether it's for a weighing scale or a force measurement system, having precise data is key. However, engineers sometimes overlook the importance of environmental factors. Temperature and humidity can affect performance. Monitoring these conditions is essential for optimal operation. Emphasizing these details can lead to significant improvements in project outcomes.

Key Features of a 1kg Load Cell for Project Applications

A 1kg load cell is a vital component for various projects. It measures small weights accurately, making it ideal for prototypes. With high precision, it can detect even slight changes in force. Many applications benefit from this compact technology. It connects easily with microcontrollers. Thus, it's user-friendly for beginners and experts alike.

Key features include its durability and reliability. It can withstand different environments, which adds to its versatility. The sensor's response time is impressive, allowing real-time data collection. This is crucial for automation and control systems.

However, users must be cautious about load cell calibration. Improper calibration can lead to inaccurate readings. It's essential to regularly check the sensor's performance. Understanding these limitations can lead to better project outcomes.

Advantages of Precision Measurement in Various Projects

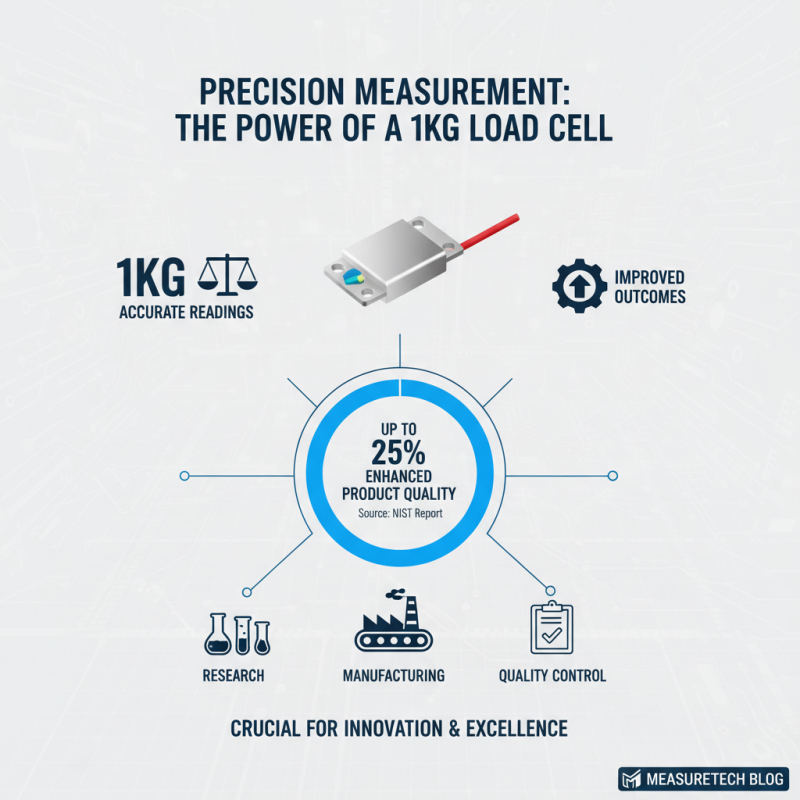

Precision measurement is crucial in many industries. A 1kg load cell offers numerous advantages. It provides accurate readings, which can lead to improved outcomes. According to a report from the National Institute of Standards and Technology, precision measurement can enhance product quality by up to 25%. This accuracy is vital for applications in research, manufacturing, and quality control.

When using a 1kg load cell, projects can benefit from increased reliability. In one study, load cells were shown to reduce measurement errors by 40%. This level of precision can prevent costly mistakes. In sensitive environments, even minor errors can lead to significant setbacks. Using high-quality load cells helps maintain consistency across various stages of production.

However, not all implementations are perfect. Factors like temperature changes can affect performance. Users must calibrate devices regularly. A lack of proper maintenance may lead to less reliable data. Attention to these details is essential for achieving optimal results. The quest for accuracy continues to be both a challenge and a necessity in many engineering projects.

Cost-Effectiveness of 1kg Load Cells in Prototyping

Using a 1kg load cell in prototyping brings significant cost-effectiveness. Many startups and projects operate on tight budgets. A load cell typically costs between $10 to $50. This is low compared to more complex weighing systems. Savings multiply in mass production, where even minor reductions in cost per unit matter.

A recent report from industry analysts noted that over 60% of prototyping expenses come from sensors and measurement devices. By integrating a 1kg load cell, developers can maintain accuracy without overspending. Many advanced systems aren’t always necessary. Simplicity can drive innovation too. Testing designs with a basic load cell allows for quick iterations.

**Tip:** Consider purchasing in bulk for additional savings. Suppliers often offer discounts for larger orders.

The small size of 1kg load cells also makes them versatile. They fit easily into various projects and prototypes. However, their sensitivity may require careful calibration. Improper setups can lead to errors. It's a balance between affordability and precision. Avoid the temptation to compromise quality for lower costs.

**Tip:** Regularly check calibration to ensure reliability in your results.

Top 10 Benefits of Using a 1kg Load Cell in Your Projects

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| High Accuracy | 1kg load cells provide precise measurements essential for accurate data collection. | Affordable pricing allows for high-quality prototypes without breaking the budget. |

| Compact Size | Small and lightweight, making them ideal for various applications. | Lower shipping costs due to lighter weight. |

| Versatile Applications | Can be used in different industries, like robotics, food, and packaging. | Cost savings across diverse project needs. |

| Ease of Integration | Simple to integrate into existing electronic systems. | Lower development costs due to reduced integration time. |

| Low Power Consumption | Energy-efficient operation, ideal for battery-operated devices. | Reduced energy costs in long-term applications. |

| High Sensitivity | Can detect minor changes in load, ensuring precise measurements. | Improves overall effectiveness of devices without extra cost. |

| Robust Design | Durable construction ensures longevity and reliability. | Fewer replacements lead to cost savings over time. |

| Good Temperature Stability | Maintains performance under varying temperature conditions. | Reduces the need for temperature compensation circuitry. |

| Scalable Solutions | Can be easily scaled for larger projects by combining multiple units. | Cost-efficient expansion of measurement capabilities. |

| User-Friendly | Easy to use with minimal technical expertise required. | Lowers training costs for team members. |

Applications of 1kg Load Cells Across Different Industries

1kg load cells are versatile components used across various industries. In the manufacturing sector, they enable precise weight measurement for quality control. This ensures that products meet required specifications. For instance, they are used in packaging lines to confirm the weight of products before they are sealed. However, some setups may face challenges in calibration, which can lead to inaccuracies.

In the healthcare industry, 1kg load cells find applications in medical scales. Hospitals and clinics rely on them for accurate patient weight measurement. This data is crucial for medication dosing and health assessments. Occasionally, load cells might drift over time, necessitating regular recalibration. Not addressing this can affect patient care.

In the agricultural sector, these load cells help in weighing produce. Farmers use them to optimize load sizes for transport. Proper measurement maximizes efficiency and reduces waste. On the downside, environmental factors like humidity can impact accuracy. This underscores the need for careful installation and monitoring.

Related Posts

-

How to Calibrate Your Load Cell 1kg for Accurate Measurements

-

Global Sourcing Revolution: How China's Best Thin Load Cells Set the Standard for Quality and Reliability

-

Top Applications of Donut Load Cells in 2025 You Should Know About

-

7 Key Tips to Maximize the Accuracy of Beam Type Load Cells for Optimized Performance

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs

-

Rise of Chinese Manufacturing in Micro Load Cells Amidst US China Tariff Challenges