sales@loadcellsensor.com

sales@loadcellsensor.com

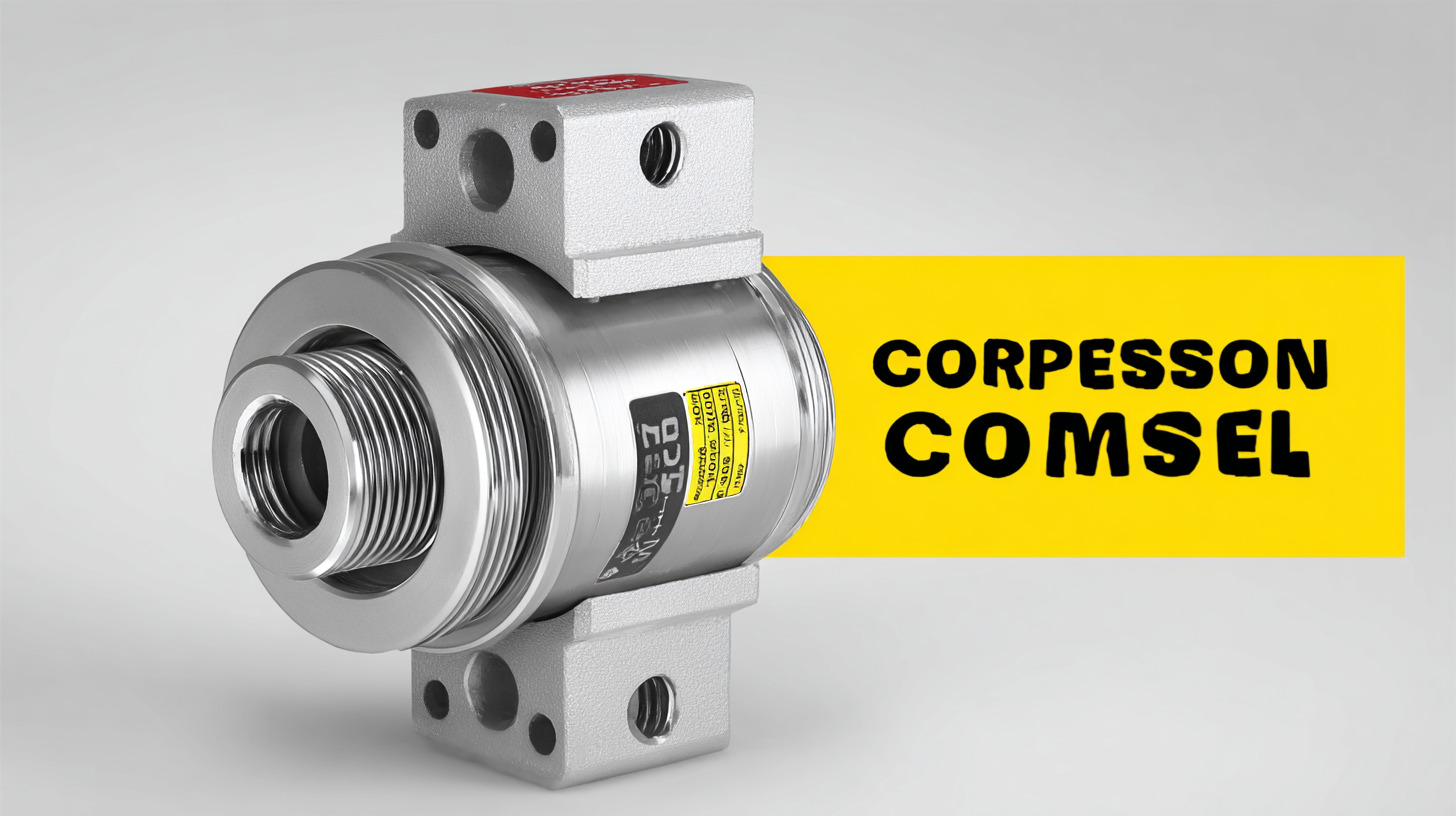

Discovering the Best Compression Load Cells: A Global Buyer’s Guide for Performance and Reliability

In the modern industrial landscape, the demand for precision in weighing and measurement applications has led to the rising popularity of Compression Type Load Cells. According to a recent report by MarketsandMarkets, the load cell market is projected to reach $4.2 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth is driven by the increasing need for accurate data collection in various sectors, including manufacturing, automotive, and aerospace. Compression load cells stand out due to their robust design and ability to withstand harsh environments, making them ideal for heavy-duty applications. As industries continue to embrace automation and smarter technologies, understanding the nuances of selecting the best compression load cells becomes essential for ensuring performance and reliability in operations. This buyer’s guide aims to navigate through the intricacies of compression type load cells, offering insights into their functionality, applications, and key specifications to help buyers make informed decisions.

Emerging Technologies Shaping Compression Load Cell Performance by 2025

As we look forward to 2025, emerging technologies are poised to greatly enhance the performance and reliability of compression load cells. Innovations in materials, such as high-performance polymer-derived ceramics, have the potential to significantly improve the durability and weight profile of load cells, making them more suitable for diverse applications including industrial automation and structural monitoring. Additionally, advancements in data compression algorithms, like the newly developed Zstandard, which offers a 42% increase in compression speed, are critical for managing the data generated by these sophisticated sensors.

Tip: When selecting compression load cells, consider the materials used in their construction. Load cells made with advanced ceramics may provide better stability and longevity, reducing the need for replacements and maintenance.

Furthermore, the integration of hydrogen compressors into existing infrastructures marks a pivotal shift toward sustainable energy solutions. As the industry increasingly adopts fuel cell technology, compatible load cells will play a crucial role in ensuring accurate measurements during hydrogen production and storage processes.

Tip: Stay informed about the compatibility of load cells with emerging technologies. A load cell that can adapt to new energy systems will offer better future-proofing for your investments.

Key Features to Look for in High-Quality Compression Load Cells

When selecting high-quality compression load cells, there are several key features to consider that will ensure optimal performance and reliability. One of the most critical aspects is accuracy. A precise load cell minimizes the margin for error, thus providing trustworthy measurements. Look for load cells with a low percentage of non-linearity and hysteresis to guarantee consistent output across various load ranges.

Another important feature is the load cell's construction materials. Load cells made from stainless steel or other durable materials can withstand harsh environments and maintain their performance over time. Additionally, consider the degree of protection offered by the load cell, such as IP ratings, which indicate its resistance to dust and moisture.

**Tips:** When evaluating potential load cells, always check for temperature stability and sensitivity ratings, as these factors will influence performance in varying conditions. It's also wise to choose load cells with a robust manufacturer warranty, as this can be an indicator of the product's quality and the manufacturer’s confidence in it.

Discovering the Best Compression Load Cells: A Global Buyer’s Guide for Performance and Reliability - Key Features to Look for in High-Quality Compression Load Cells

| Feature | Description | Importance | Typical Value Range |

|---|---|---|---|

| Capacity | The maximum load that the cell can measure without failure. | Critical for ensuring the load cell can handle intended applications. | 10 kg - 30,000 kg |

| Accuracy | The degree of closeness of the measured value to the actual load. | Essential for precision applications in industries like manufacturing. | ±0.1% to ±0.5% |

| Material | The material from which the load cell is made affects durability and performance. | Influences resistance to environmental factors and longevity. | Aluminum, Stainless Steel |

| Operating Temperature | The range of ambient temperatures in which the load cell can operate effectively. | Critical for maintaining stability in various environmental conditions. | -40°C to 85°C |

| Output Type | The signal type provided by the load cell, such as analog or digital. | Determines compatibility with measurement systems and ease of integration. | Analog Voltage, Digital (RS232, RS485) |

| Protection Rating | Ingress Protection (IP) ratings that indicate protection against dust and water. | Key for applications in harsh environments. | IP65, IP67 |

Understanding Load Cell Calibration and Its Impact on Reliability

In the realm of load cell technology, understanding load cell calibration is paramount for ensuring performance and reliability. Load cells are the backbone of many industrial applications, converting force into an electrical signal. According to a recent report by the International Society of Automation, improper calibration can lead to measurement errors of up to 5%, significantly impacting operational efficiency and product quality. Therefore, regular calibration checks are essential for maintaining accuracy.

Tip: Implement a routine calibration schedule based on the manufacturer’s recommendations to avoid drift in measurements over time. Regular checks not only enhance reliability but also comply with industry regulations.

Moreover, the impact of environmental factors on calibration must not be overlooked. Factors such as temperature fluctuations, humidity, and mechanical stress can cause shifts in calibration, potentially compromising the load cell's reliability. A study from the National Institute of Standards and Technology reveals that temperature variations can lead to a calibration shift of up to 2% per degree Celsius in some load cell types.

Tip: Consider using temperature-compensated load cells if your operations occur in varying environmental conditions, ensuring that calibration remains unaffected by external changes. Maintaining optimal calibration strategies is crucial to maximizing the longevity and performance of your load cells.

Global Market Trends and Their Influence on Load Cell Designs

As the global market for load cells continues to evolve, several key trends are shaping their design and performance. Increasing demand for precision in industries such as aerospace and healthcare drives innovation in compression load cells. Enhanced sensitivity and accuracy are pivotal, as businesses seek to optimize processes and improve product quality, ultimately influencing how manufacturers approach load cell technology.

Moreover, sustainability has emerged as a vital consideration in the design of load cells. With a growing emphasis on environmentally friendly practices, manufacturers are focusing on using sustainable materials and energy-efficient production methods. This shift not only meets regulatory requirements but also appeals to a market increasingly interested in sustainable solutions. Consequently, load cell designs are adapting, incorporating features that promote longevity and reduce environmental impact while maintaining high-performance standards necessary for commercial applications.

Best Practices for Maintaining and Sustaining Compression Load Cells

Maintaining and sustaining compression load cells is crucial for ensuring their long-term performance and reliability. To achieve optimal results, it's essential to follow best practices that enhance the lifespan of these vital components. Regular calibration and thorough inspections can help identify potential issues before they lead to significant failures. Additionally, keeping load cells clean and free from contaminants will help maintain their accuracy and functionality.

Maintaining and sustaining compression load cells is crucial for ensuring their long-term performance and reliability. To achieve optimal results, it's essential to follow best practices that enhance the lifespan of these vital components. Regular calibration and thorough inspections can help identify potential issues before they lead to significant failures. Additionally, keeping load cells clean and free from contaminants will help maintain their accuracy and functionality.

Tips for prolonging the life of your compression load cells include regularly checking for signs of wear or damage, ensuring proper installation to avoid mechanical stress, and avoiding overload conditions that could compromise their integrity. Incorporating protective enclosures can also shield load cells from environmental factors that might affect their performance.

Furthermore, integrating energy storage technologies into your operational framework can enhance the efficiency of compression load cells. As developments in energy systems continue to evolve, staying informed about the latest trends and implementing sustainable adaptation policies is vital. This proactive approach not only boosts performance but also supports the broader goals of renewable energy integration and decarbonization, ultimately leading to a more sustainable future.