sales@loadcellsensor.com

sales@loadcellsensor.com

15 Best Practices for Using Tension Compression Load Cell in Industry

In the modern industrial landscape, accurate measurement and monitoring of loads are crucial for ensuring safety, efficiency, and productivity. One essential tool that plays a pivotal role in achieving these goals is the Tension Compression Load Cell. These versatile devices are designed to measure both tension and compression forces, making them invaluable in various applications ranging from manufacturing to construction. However, to fully leverage their capabilities, it is vital to follow best practices that ensure optimal performance and reliability.

In this blog, we will delve into 15 best practices for using Tension Compression Load Cells in industry. By adhering to these guidelines, organizations can enhance accuracy, reduce downtime, and ultimately improve the overall functionality of their operations.

Understanding Tension Compression Load Cells: Basics and Applications

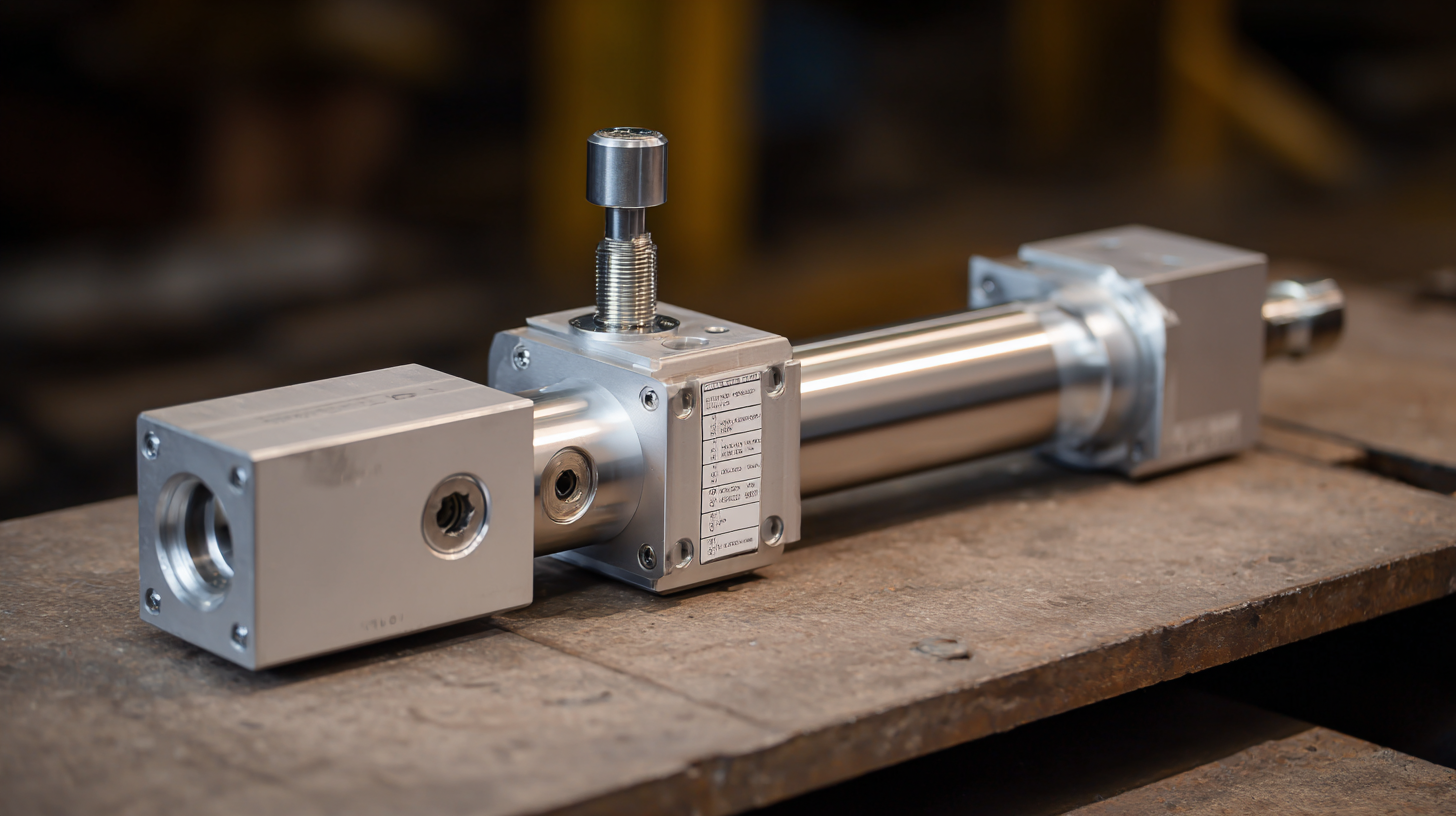

Tension compression load cells are essential components in various industrial applications, providing accurate measurements of force and weight. Understanding their operation and application can significantly enhance productivity and reliability in manufacturing and research processes. These load cells can handle a wide range of nominal loads, from 0.3 kg to as much as 500 tons, making them versatile tools for both small-scale and heavy-duty operations. Their design variety includes platform, bending, shear, S-type, and compression cells, catering to diverse industry needs.

The growth of the force sensor market underlines the increasing demand for precision measurement solutions. According to recent projections, the global force sensor market is expected to grow from USD 3.01 billion in 2025 to USD 4.54 billion by 2033, at a CAGR of 5.3%. This expansion is partially driven by advancements in sensor technology and the increasing application of tension compression load cells in sectors such as pharmaceuticals, bioreactor systems for stem cell research, and machinery. The integration of these systems into bioreactors, particularly, showcases their capability in supporting the osteogenic commitment of stem cells through precise force application, demonstrating their significance in both industrial and biomedical fields.

Key Factors Influencing the Performance of Tension Compression Load Cells

When it comes to the performance of tension compression load cells, several key factors come into play that can significantly influence their effectiveness in industrial applications. First and foremost, the selection of materials used in the construction of load cells is critical. High-quality materials such as stainless steel or aluminum not only enhance durability but also reduce errors caused by environmental changes. Additionally, the design of the load cell, including its geometry and loading features, impacts its sensitivity and accuracy. Load cells must be engineered to minimize hysteresis and maximize response time to ensure reliable measurements, particularly in dynamically varying applications.

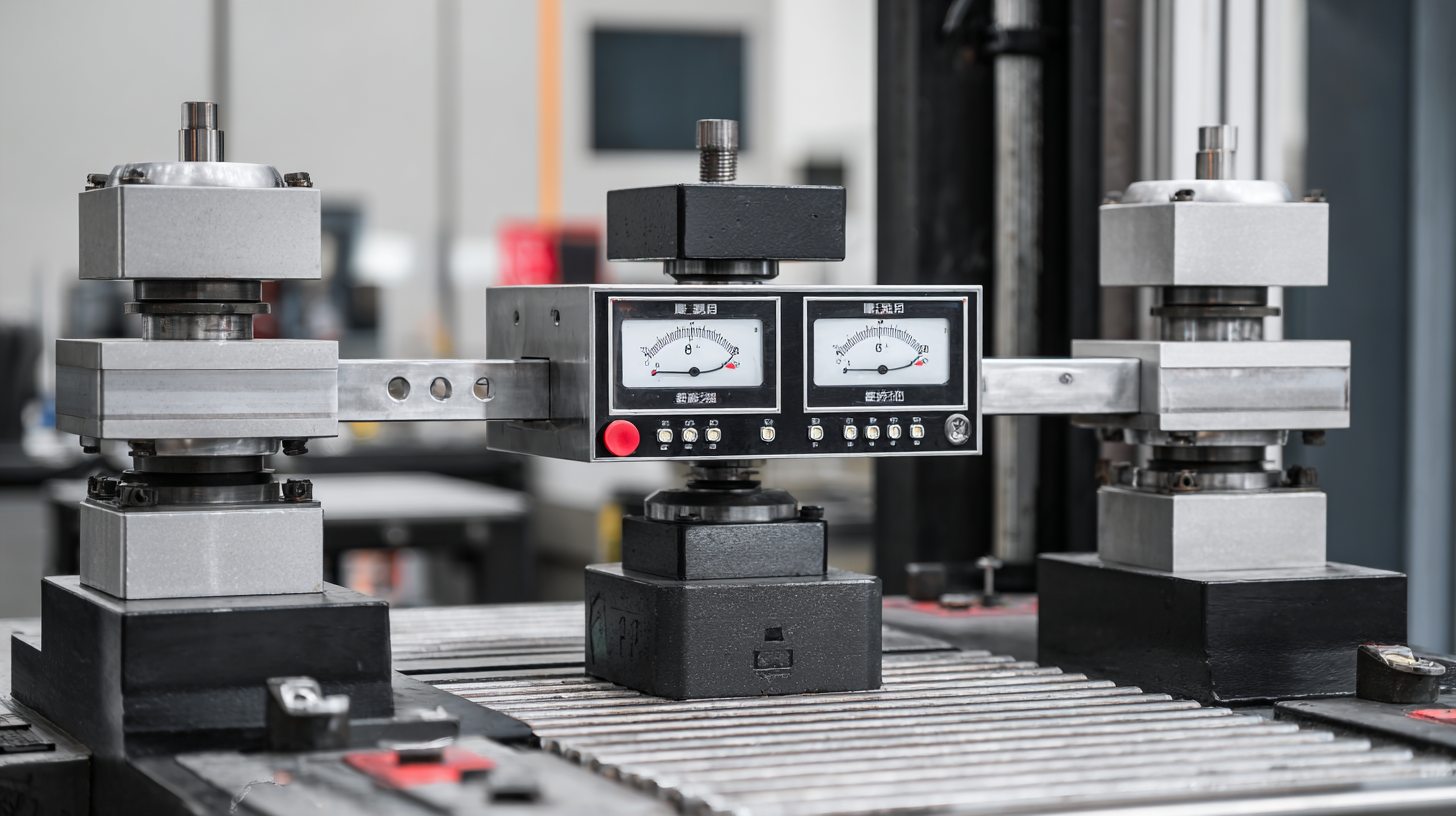

Another vital factor influencing load cell performance is the calibration process. Accurate calibration against known weights is essential for maintaining precision over time. Regular calibration checks can prevent drift in readings that may occur due to wear or changes in environmental conditions. Furthermore, environmental factors such as temperature fluctuations, humidity, and electromagnetic interference can also affect performance. Choosing load cells with appropriate environmental protection and conducting installations that mitigate these external influences contribute significantly to sustained operational integrity and accuracy in load measurement tasks.

Best Practices for Installation and Calibration of Load Cells

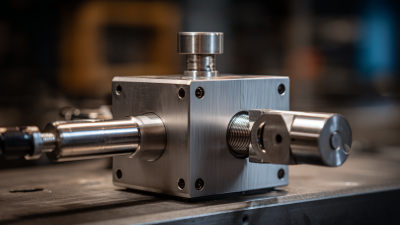

When it comes to the installation and calibration of tension compression load cells, adhering to best practices is crucial for achieving accurate and reliable measurements. One of the first steps in the installation process is to ensure that the load cell is mounted on a stable and flat surface. This prevents any misalignment that could lead to erroneous readings. Additionally, using the right mounting hardware is essential; the use of specialized mounting kits can help to minimize mechanical stress on the load cell, thereby enhancing its longevity and performance.

Calibration is another vital aspect that should not be overlooked. It is recommended to perform a multi-point calibration to account for non-linearity and hysteresis in the load cell’s output. This involves applying known weights at various points and recording the corresponding output readings. Regularly scheduled recalibrations are also important to maintain measurement accuracy over time, particularly in industrial environments where factors such as temperature fluctuations and mechanical wear can affect performance. By following these best practices in installation and calibration, industries can ensure their tension compression load cells deliver precise and consistent results.

Common Challenges and Solutions in Load Cell Monitoring

In industrial applications, tension compression load cells are pivotal for accurate measurement and monitoring of forces. However, effectively utilizing these devices often presents challenges, particularly in terms of precision and environmental conditions. According to a report by Research and Markets, the global load cell market is projected to grow at a CAGR of 4.9% from 2020 to 2025, highlighting the increasing reliance on load cells in various sectors. To address common challenges such as drift and temperature sensitivity, industries are advised to implement calibration protocols that ensure high accuracy even under fluctuating conditions.

Moreover, the impact of mechanical stress and physical interference can significantly affect load cell performance. A study conducted by the International Journal of Metrology states that nearly 15% of load cell errors stem from misalignment or improper installation. To mitigate these issues, companies should invest in robust mounting techniques and regular maintenance checks. Additionally, integrating advanced data monitoring systems can help in identifying discrepancies in real-time, thereby enabling prompt corrective actions. By focusing on these common challenges and their solutions, businesses can enhance the reliability and accuracy of their load cell applications, ultimately leading to improved operational efficiency.

15 Best Practices for Using Tension Compression Load Cell in Industry

Enhancing Accuracy: Maintenance Tips for Tension Compression Load Cells

Maintaining the accuracy of tension compression load cells is crucial for ensuring reliable measurements in industrial applications. Regular maintenance practices can significantly extend the lifespan of these devices while enhancing their performance. One key tip is to conduct periodic calibration checks. This involves comparing the output of the load cell to a known reference load, ensuring that any deviations are promptly addressed. Regular calibration helps to identify wear and tear or other issues that may affect precision, allowing for timely adjustments.

Another important aspect of maintenance is the environment in which load cells operate. Protecting them from extreme temperatures, moisture, and corrosive substances is vital. Using appropriate housing or enclosures can shield these sensitive devices from external factors that may compromise their integrity and accuracy. Additionally, routine visual inspections for signs of damage or wear can prevent potential failures. Keeping the load cell clean and free from contaminants, such as dust or debris, will also contribute to its long-term reliability and accuracy, making it essential to incorporate these practices into regular operational protocols.

Related Posts

-

Exploring the Use of Thin Load Cells in Heavy Machinery and Challenges Faced in Precision Measurements

-

Advantages of Utilizing Ring Load Cells for Precise Industrial Measurements

-

Discovering the Future of Precision: Button Load Cells at the 2025 Canton Fair

-

Top 10 Micro Load Cell Manufacturers from China at the 137th Canton Fair

-

How to Choose the Best Tension Load Cell for Your Industrial Applications

-

Exploring Innovative Alternatives to the Best Tension Compression Load Cell for Global Buyers