sales@loadcellsensor.com

sales@loadcellsensor.com

Best Tension Load Cell for Accurate Weight Measurement?

In the world of weight measurement, precision is paramount. Experts agree that the right choice of a Tension Load Cell can significantly influence results. Dr. Angela Roberts, a renowned specialist in load measurement technology, states, "Selecting the best Tension Load Cell is crucial for achieving accurate measurements."

Tension load cells play a vital role in various industries, including manufacturing and logistics. They measure the force applied to an object. Accuracy in load measurement can prevent costly errors in production. Sometimes, users may overlook the impact of environmental factors on these devices. Factors like temperature and humidity can affect performance.

In selecting a Tension Load Cell, one must consider sensitivity and calibration. Choosing a model that suits specific needs is not always straightforward. Often, individuals may choose based on cost rather than performance. This can lead to complications down the road. Reflecting on these choices can foster better decisions in the future.

Definition and Functionality of Tension Load Cells

Tension load cells are essential devices for accurate weight measurement in various industries. They function by measuring the force exerted along a single line. This allows for precise readings of weights in mechanical systems, warehouses, and manufacturing plants. Their design is often compact, making them easy to integrate into existing machinery.

When choosing a tension load cell, consider the environment. Moisture or extreme temperatures can affect their performance. Ensure proper installation by securing them properly. Always check if they align correctly with the load direction. A slight misalignment can lead to inaccurate readings.

Tips for ensuring accuracy include regular calibrations. Even small changes over time can impact performance. Installing a protective casing could safeguard against dust and moisture. Regular maintenance is also crucial. Neglecting this can lead to unforeseen issues that are costly to fix.

Consider all these factors before making a decision.

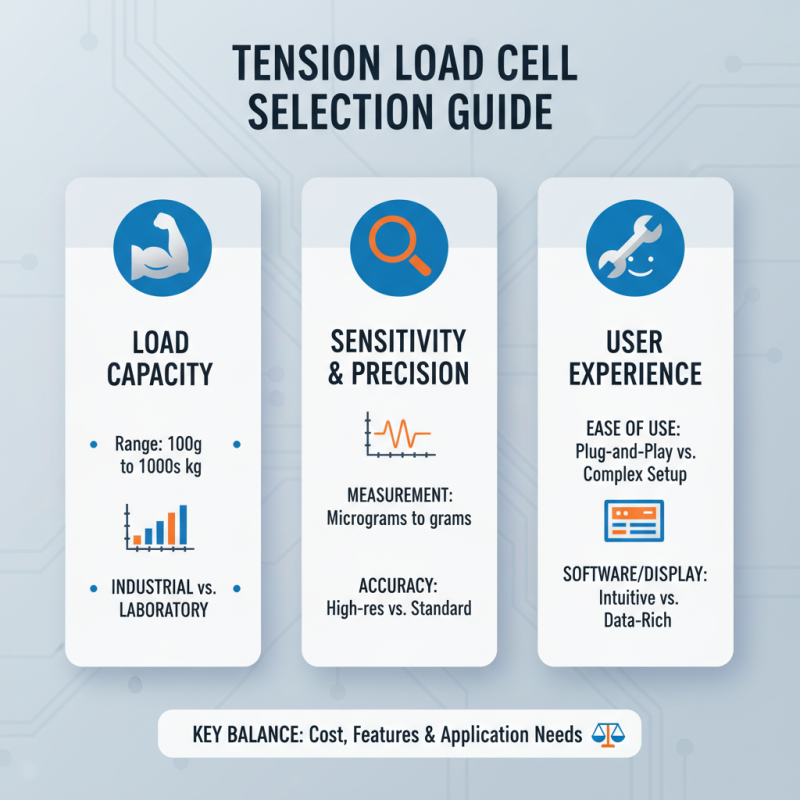

Key Factors to Consider When Choosing a Tension Load Cell

When choosing a tension load cell for accurate weight measurement, several key factors need consideration. Load cells vary significantly in specification, and understanding these can impact your decision. Capacity is crucial; select one that suits your maximum expected load. Typically, load cells come rated for specific ranges, often spanning from a few grams to several tons based on industry reports.

Precision is another vital factor. Look for a load cell with minimal non-linearity, ideally within ±0.1%. This ensures accurate readings throughout its operational range. Additionally, environmental factors can affect performance. Consider temperature ranges and humidity levels where the load cell will be used.

Tips: For outdoor use, opt for weather-resistant materials. Calibration can affect accuracy. Regular checks can minimize drift. Be mindful, installing improperly can lead to mishaps, resulting in inaccurate readings. Always prioritize the installation environment's stability, as vibrations can skew results. Remember, even minor errors can translate into significant discrepancies in high-stakes applications. Choosing the right load cell requires careful consideration of these aspects to ensure reliable performance.

Top Applications for Accurate Weight Measurement Using Tension Load Cells

Tension load cells are vital in various applications requiring precise weight measurement. They help in monitoring tensile forces during lifting operations. Industries like construction rely on accurate data to ensure safety. In manufacturing, these devices improve quality control. A miscalculation can lead to failures.

In logistics, tension load cells play a crucial role. They assist in determining the weight of cargo accurately. This prevents overloading and potential accidents. In the field of automation, they ensure consistent performance. Maintaining accuracy can be challenging, as environmental factors affect readings. Regular calibration helps but is often overlooked.

Understanding the installation process is essential. Poorly aligned components may skew results. Training personnel to handle these devices is a must. This ensures they can identify potential issues early. Being aware of these aspects can enhance efficiency. Ultimately, companies can achieve better results by improving their usage of tension load cells.

Best Tension Load Cell for Accurate Weight Measurement

Comparison of Leading Brands and Models of Tension Load Cells

When choosing a tension load cell, understanding the differences among leading models is crucial. Various brands offer a wide range of features. These can include different load capacities and sensitivity levels. Some units excel in precision, while others tend to be more user-friendly. It can be tricky to find the right balance between these attributes.

Many users report mixed experiences. Some load cells provide excellent results in controlled environments but fail under variable conditions. Others might be overly complicated, hindering accurate readings. Additionally, calibration processes often differ, affecting user experience. It can be frustrating to navigate these challenges, especially for those new to this technology.

User reviews help shed light on the strengths and weaknesses of different models. Some devices are praised for their durability, only to fall short in terms of support. Real-world applications often highlight performance gaps that lab tests overlook. Therefore, a thorough comparison is essential. Gathering as much information as possible ensures better decisions, even if some uncertainty remains.

Maintenance Tips for Ensuring Accuracy in Tension Load Cells

Tension load cells are critical for ensuring precise weight measurements in various industries. To maintain their accuracy, regular maintenance is essential. Periodic calibration is necessary; small variations can lead to significant errors. Ensure the load cell is calibrated against known weights, checking for any discrepancies. Regular checks are vital.

Environmental factors can affect performance. Dust or moisture may impact readings. It's wise to keep the load cell clean and protected from harsh conditions. Use protective covers if necessary. Examine the cables for wear and tear. Frayed wires can cause erratic readings.

Every user may overlook these small details. However, these oversights can lead to severe consequences. Monitoring load cell performance regularly is crucial. Think about how often adjustments are made. A few minutes spent on maintenance could save time and resources later. Weight accuracy isn't a luxury; it’s a necessity in many applications.

Best Tension Load Cell for Accurate Weight Measurement? - Maintenance Tips for Ensuring Accuracy in Tension Load Cells

| Load Cell Type | Capacity (kg) | Accuracy (%) | Temperature Range (°C) | Maintenance Frequency | Calibration Method |

|---|---|---|---|---|---|

| Hydraulic Load Cell | 1000 | 0.02 | -10 to 50 | Every 6 months | External Weight Calibration |

| Digital Load Cell | 2000 | 0.01 | 0 to 40 | Every 12 months | Built-in Calibration Procedure |

| Strain Gauge Load Cell | 500 | 0.02 | -20 to 60 | Every 6 months | Manual Calibration with Standards |

| S-Beam Load Cell | 1500 | 0.03 | -10 to 70 | Every 9 months | Factory Calibration Recommended |

Related Posts

-

5 Essential Tips for Choosing the Right Tension Compression Load Cell

-

Unique Challenges Encountered with Button Load Cell for Global Importers

-

Top Applications of Donut Load Cells in 2025 You Should Know About

-

Top Load Cell Types and Their Applications in Industrial Weighing Systems

-

Top 10 Micro Load Cell Manufacturers from China at the 137th Canton Fair

-

Top Strategies for Selecting the Best 5kg Load Cell for Your Business Needs