sales@loadcellsensor.com

sales@loadcellsensor.com

Essential Checklist for Choosing the Best Inexpensive Load Cell

In the rapidly evolving field of sensor technology, the demand for reliable and cost-effective solutions has led to a surge in the popularity of inexpensive load cells. According to a recent market report by Research and Markets, the global load cell market is projected to reach USD 1.3 billion by 2025, driven by the increasing applications in industrial automation and IoT devices. However, selecting the right inexpensive load cell can be challenging due to common issues such as accuracy, calibration, and compatibility with existing systems. These problems can significantly affect the performance and reliability of measuring systems used in various industries, from manufacturing to healthcare. Therefore, understanding the critical factors in choosing an inexpensive load cell is essential for both new and experienced users, ensuring optimal performance while remaining within budget.

Key Factors to Consider When Selecting Cost-Effective Load Cells for Your Application

When selecting cost-effective load cells for your application, it's essential to consider several key factors that can significantly impact performance and reliability. One of the most critical aspects is the load cell's accuracy and sensitivity. According to industry reports, the performance of affordable load cells can vary drastically, with some achieving accuracies within 0.01% of the measured load while others might only offer ±0.5%. Therefore, understanding your specific measurement requirements is crucial to ensuring you choose a model that won't compromise the overall effectiveness of your system.

Another vital factor is the environmental suitability of the load cells. Choosing a load cell designed to operate in specific temperature ranges or resistant to humidity and noise can prevent performance degradation in undesirable conditions. Recent advancements in sensor technology, like those found in sophisticated tactile sensing systems, highlight the importance of using the right sensors in dynamic environments. By investing in load cells with robust environmental ratings, users can enhance the longevity and durability of their applications while minimizing maintenance costs. Always evaluate your operational environment and select a load cell that aligns with those conditions to maintain optimal functionality.

Understanding Load Cell Types: Strain Gauge, Hydraulic, and Pneumatic Options

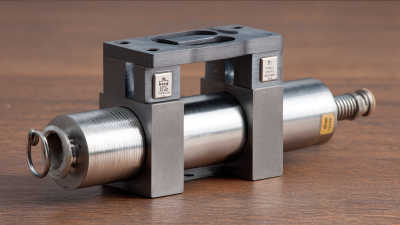

When choosing an inexpensive load cell, it's essential to understand the different types available, such as strain gauge, hydraulic, and pneumatic load cells. Strain gauge load cells are the most commonly used due to their affordability and accuracy. They operate by measuring the deformation of a strain gauge attached to a flexible material, providing precise readings across various applications.

Hydraulic load cells, on the other hand, use fluid pressure to measure force. They are particularly suitable for heavy-duty applications where high capacity is required, making them ideal for industrial environments. However, they might come at a higher cost compared to strain gauge options.

Pneumatic load cells utilize air pressure for measurements and offer unique benefits, especially in environments where electronic components may be prone to damage. They are typically more expensive but can provide excellent durability in challenging settings.

**Tip:** Always consider the specific application requirements before making a choice, such as the load range and environmental conditions. **Tip:** Don’t overlook the importance of calibration to ensure accuracy after installation, regardless of the load cell type you opt for.

Load Cell Types and Their Cost Effectiveness

Evaluating Accuracy and Precision: Industry Standards for Load Cells

When selecting an inexpensive load cell, evaluating accuracy and precision is paramount. According to the International Society of Automation (ISA), load cells should meet specific industry standards to ensure reliable measurements. The accuracy of a load cell is often defined as the maximum difference between the measured value and the true value, typically expressed as a percentage of the full scale output. For instance, many industrial applications adhere to the IEC 60068-2-6 standard, which stipulates acceptable accuracy levels that can be as low as 0.1% of full scale for precision applications.

In addition to accuracy, precision also plays a critical role in load cell performance. The National Institute of Standards and Technology (NIST) emphasizes that precision is related to the repeatability of measurements, usually quantified through a standard deviation. For inexpensive load cells, aiming for a precision level within 0.2% is a practical benchmark, ensuring that the devices can deliver consistent results over multiple tests. By adhering to recognized standards, users can make informed choices about load cells that not only fit their budget but also uphold the integrity of their measurements.

Essential Checklist for Choosing the Best Inexpensive Load Cell - Evaluating Accuracy and Precision: Industry Standards for Load Cells

| Parameter | Standard Value | Measurement Unit | Industry Standard |

|---|---|---|---|

| Maximum Capacity | 1000 | kg | OIML R60 |

| Accuracy Class | C3 | N/A | ISO 376 |

| Non-linearity | 0.03% | % F.S. | ASTM E74 |

| Hysteresis | 0.02% | % F.S. | ASTM E74 |

| Temperature Effect | ±0.01% | % F.S./°C | ISO 1133 |

The Importance of Load Cell Material: Durability and Environmental Resistance

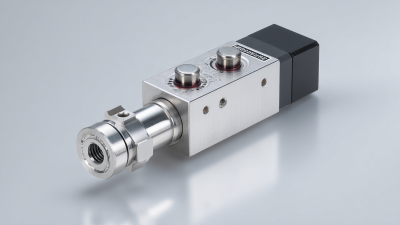

When selecting an inexpensive load cell, the material it is made from plays a crucial role in determining its longevity and capacity to withstand various environmental factors. Opting for high-quality materials such as stainless steel or aluminum can significantly enhance the durability of the load cell. Stainless steel, for instance, not only provides robust strength but also offers excellent corrosion resistance, making it ideal for use in harsh environments. On the other hand, aluminum is lighter and has a favorable strength-to-weight ratio, although it may require protective coatings in more demanding applications.

When selecting an inexpensive load cell, the material it is made from plays a crucial role in determining its longevity and capacity to withstand various environmental factors. Opting for high-quality materials such as stainless steel or aluminum can significantly enhance the durability of the load cell. Stainless steel, for instance, not only provides robust strength but also offers excellent corrosion resistance, making it ideal for use in harsh environments. On the other hand, aluminum is lighter and has a favorable strength-to-weight ratio, although it may require protective coatings in more demanding applications.

Tip: Always check the load cell's rating for environmental factors like humidity and temperature ranges. Load cells intended for outdoor use should be sealed or treated to prevent moisture ingress.

In addition to material choice, it's important to consider the load cell’s application and environment. Load cells exposed to chemical substances should have materials compatible with such environments to avoid degradation. For applications in food processing or medical fields, materials that meet stringent hygiene standards are essential.

Tip: Consult manufacturer specifications for applications of different materials to ensure the selected load cell will perform optimally in its intended setting. This can prevent costly downtime and replacements in the future.

Cost vs. Quality: How to Assess Value in Inexpensive Load Cells

When selecting an inexpensive load cell, understanding the balance between cost and quality is crucial. A common misconception is that the lowest price equates to the best value. Instead, assess the specifications and performance metrics to ensure the load cell meets your operational needs. For instance, if you're using a low-cost load cell in a setup for measuring torque, consider the measurement range and precision offered by the device to avoid future complications in your projects.

Tips: Always evaluate the reputation of the manufacturer and look for user reviews regarding accuracy and durability. A case in point is the innovative use of inexpensive components like a $6 load cell combined with an Arduino; users have successfully achieved reliable results for various applications. Additionally, consider future scalability – a slightly higher initial investment might save costs on replacements or upgrades later on.

Lastly, don't overlook the importance of customer support and warranty options. A quality load cell accompanied by good support can save you time and money in troubleshooting and maintenance. By carefully weighing these factors, you can find a load cell that not only fits your budget but also provides the reliability and performance necessary for your applications.

Related Posts

-

Quality that Conquers the Globe Best Inexpensive Load Cells from China

-

Understanding the Key Technical Specifications of the Best Force Transducer and How to Choose the Right One

-

Overcoming Industry Standards: How to Choose the Best Compression Load Cell Amidst Common Challenges

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide

-

Solutions for Accurate Measurement with Micro Load Cells

-

Explore Cutting-Edge Weight Sensors at the Record-Breaking 137th Canton Fair!