sales@loadcellsensor.com

sales@loadcellsensor.com

2026 How to Choose and Use a 100kg Load Cell Effectively?

Choosing the right equipment can be challenging. A 100kg Load Cell is essential for accurate measurements. This device measures force, weight, or pressure. It plays a critical role in various applications, from industrial settings to research labs.

Understanding how to use a 100kg Load Cell effectively is key. Many users struggle to find the optimal settings. Misalignment can lead to inaccurate readings. Proper installation ensures reliability and precision. Calibration is equally important to maintain accuracy over time.

Common mistakes include overlooking the environment. Temperature fluctuations can affect readings. Regular maintenance can help mitigate these issues. Reflecting on your setup and process is crucial for effective usage. By following best practices, you can maximize the performance of your 100kg Load Cell.

Understanding Load Cells: An Overview of 100kg Load Cell Types

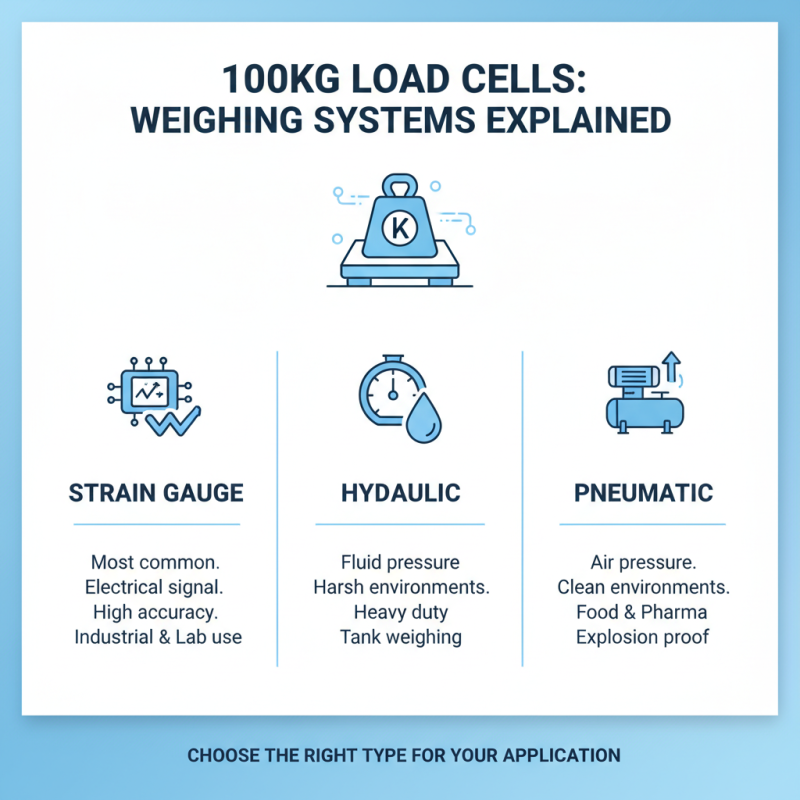

Understanding load cells is crucial for anyone involved in weighing systems. A 100kg load cell is a common choice for various applications. These cells come in different types: strain gauge, hydraulic, and pneumatic. Each type has its unique applications and benefits.

Strain gauge load cells are popular due to their accuracy. They convert force into an electrical signal. Hydraulic load cells use fluid pressure to measure weight. They are robust and ideal for heavy loads. Pneumatic load cells operate using air pressure. They are often utilized in environments where electrical devices may fail.

Tips: Choose the right load cell based on your needs. Consider accuracy, environment, and load capacity. Always check the specifications before purchase. Installation should be done carefully. Improper setup can lead to errors.

Using a load cell effectively requires proper calibration. Regular maintenance is also vital. Dust and moisture can affect performance. Remember to inspect the load cell regularly. Small issues, if ignored, can lead to larger problems later.

Finally, test the load cell with known weights. This ensures accuracy and reliability. Even with clear instructions, mistakes can happen. A little trial and error may be necessary to get it right.

Key Factors to Consider When Selecting a 100kg Load Cell

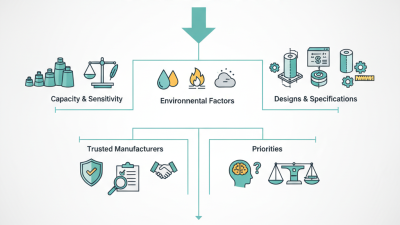

Choosing a 100kg load cell requires careful consideration of several key factors. First, consider the load cell's accuracy. Precision is vital for reliable measurements. A small error can lead to significant issues in weight-sensitive applications. Look for options with high resolution specifications to ensure you get the best data possible.

Next, examine the environmental conditions where the load cell will operate. Will it face high humidity or extreme temperatures? Some load cells are designed for harsh conditions and can withstand these factors. Pay attention to the IP rating, which indicates protection against dust and water. This can affect the lifespan and reliability of your load cell.

Finally, think about installation. The setup should be straightforward, but often it’s not. Some users experience challenges with alignment or wiring. Consider the setup space and how the load cell will be integrated with existing systems. A thoughtful design can prevent headaches down the line, helping achieve better performance.

Best Practices for Installing a 100kg Load Cell in Your Application

When installing a 100kg load cell, the foundation is crucial. An uneven or unstable surface can lead to inaccurate readings. Ensure that the load cell is mounted on a flat, solid surface. Use a spirit level to verify its positioning. Any tilt can distort measurements significantly.

Cable management is often overlooked. Ensure that the cables are arranged neatly, avoiding sharp bends or kinks. Strain relief is essential to prevent damage during operation. If the cables are pinched or pulled, it can lead to erroneous results. Taking the time to secure the cables properly will pay off in the long run.

Calibration is another area where mistakes can occur. Failing to calibrate the load cell correctly can lead to significant errors. Always follow the recommended processes for calibration. Check weights after installation to ensure accuracy. Regular checks are necessary, especially in changing environments.

Calibration and Maintenance Tips for Optimal Load Cell Performance

Calibration is crucial for ensuring that a 100kg load cell performs optimally. Calibration involves comparing your load cell's output with a known weight. Regular calibration helps maintain accuracy. Studies show that load cells can drift over time, resulting in errors of up to 1%. This drift is often influenced by environmental conditions like temperature and humidity.

Maintenance is equally important. A clean load cell is a reliable load cell. Dust and residues can interfere with its operation. Regularly inspect the load cell for signs of wear. Any physical damage can lead to inaccurate readings. The load cell should also be installed properly, avoiding excessive forces or misalignment.

Monitoring local conditions like vibrations and stray electrical currents can help prevent complications. Data indicates that over 30% of load cell errors are due to improper installation or maintenance. Reflection on these elements will not only improve longevity but also ensure that your load cell continues to provide accurate measurements. Regular checks and an understanding of limitations can enhance performance significantly.

Load Cell Performance Metrics

Troubleshooting Common Issues with 100kg Load Cells

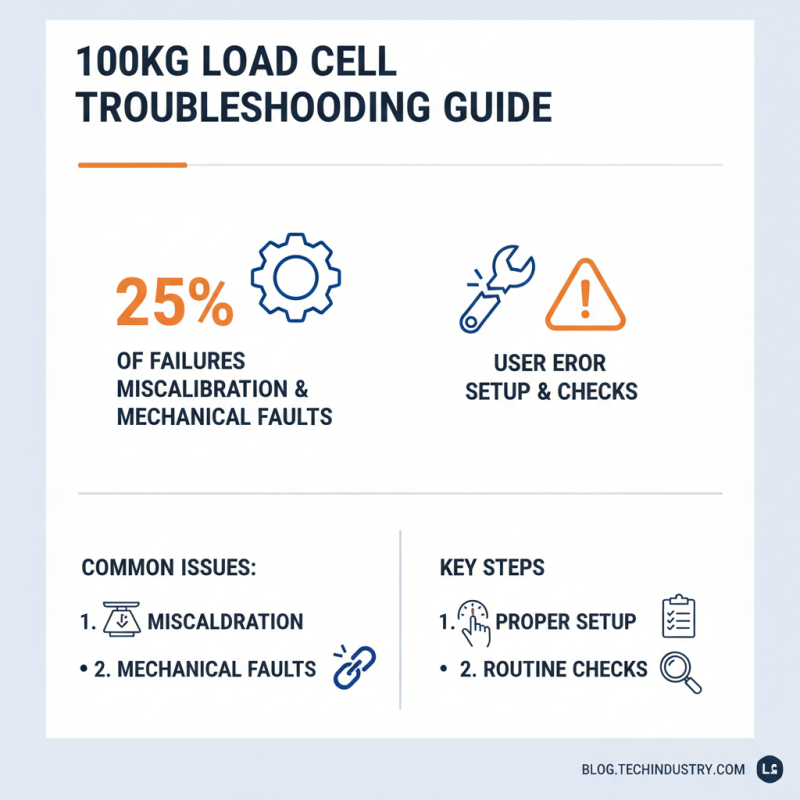

When dealing with 100kg load cells, troubleshooting is crucial. Common issues often arise from miscalibrations or mechanical faults. For example, according to industry reports, nearly 25% of load cell failures are linked to these factors. This means user error should not be overlooked during setup and routine checks.

Check the power supply first. Fluctuating voltages can lead to inaccurate readings. Ensure that your connections are secure and that the load cell operates within the specified voltage range. Loose connections can introduce noise, resulting in erratic outputs.

**Tip:** Regularly inspect the setup for mechanical stress or overload. Misalignment can lead to readings that err significantly from actual weights.

Environment matters, too. Load cells exposed to temperature changes may drift in accuracy. Embedded temperature compensation can help, but it is not always foolproof. Monitoring ambient conditions will aid in maintaining precise measurements.

**Tip:** Conduct regular calibration checks every few months. This prevents long-term drift and ensures reliability. Remember, even well-constructed systems can produce errors over time.

Related Posts

-

How to Choose the Best Tension Compression Load Cell for Your Needs?

-

How to Choose the Best Tension Load Cell for Your Industrial Applications

-

Unlocking Success with Thin Load Cells Effective Ways to Identify Quality Suppliers

-

Discovering the Future of Precision: Button Load Cells at the 2025 Canton Fair

-

Global Sourcing Revolution: How China's Best Thin Load Cells Set the Standard for Quality and Reliability

-

Overcoming Industry Standards: How to Choose the Best Compression Load Cell Amidst Common Challenges