sales@loadcellsensor.com

sales@loadcellsensor.com

2025 How to Choose the Best Biaxial Load Cell for Your Application

In the realm of precision measurement, selecting the appropriate Biaxial Load Cell is pivotal for ensuring accuracy and reliability in various applications, from industrial manufacturing to research laboratories. According to Dr. James Hartley, a renowned expert in load measurement technology, "Choosing the right Biaxial Load Cell can significantly influence the performance and quality of your entire measurement system." His insights highlight the complexity and importance of understanding the unique requirements of your application.

As the demand for precise data continues to grow across multiple sectors, the selection process for a Biaxial Load Cell becomes increasingly critical. Factors such as measurement range, environmental conditions, and the specific nature of the loads being measured must all be taken into account. This commitment to informed choices will not only enhance operational effectiveness but also optimize the longevity and dependability of measurement systems.

In this article, we will explore the essential aspects to consider when selecting the best Biaxial Load Cell for your application, ensuring that you are well-equipped to make an informed decision that meets both your immediate and long-term goals in precision measurement.

Understanding Biaxial Load Cells: Definition and Applications

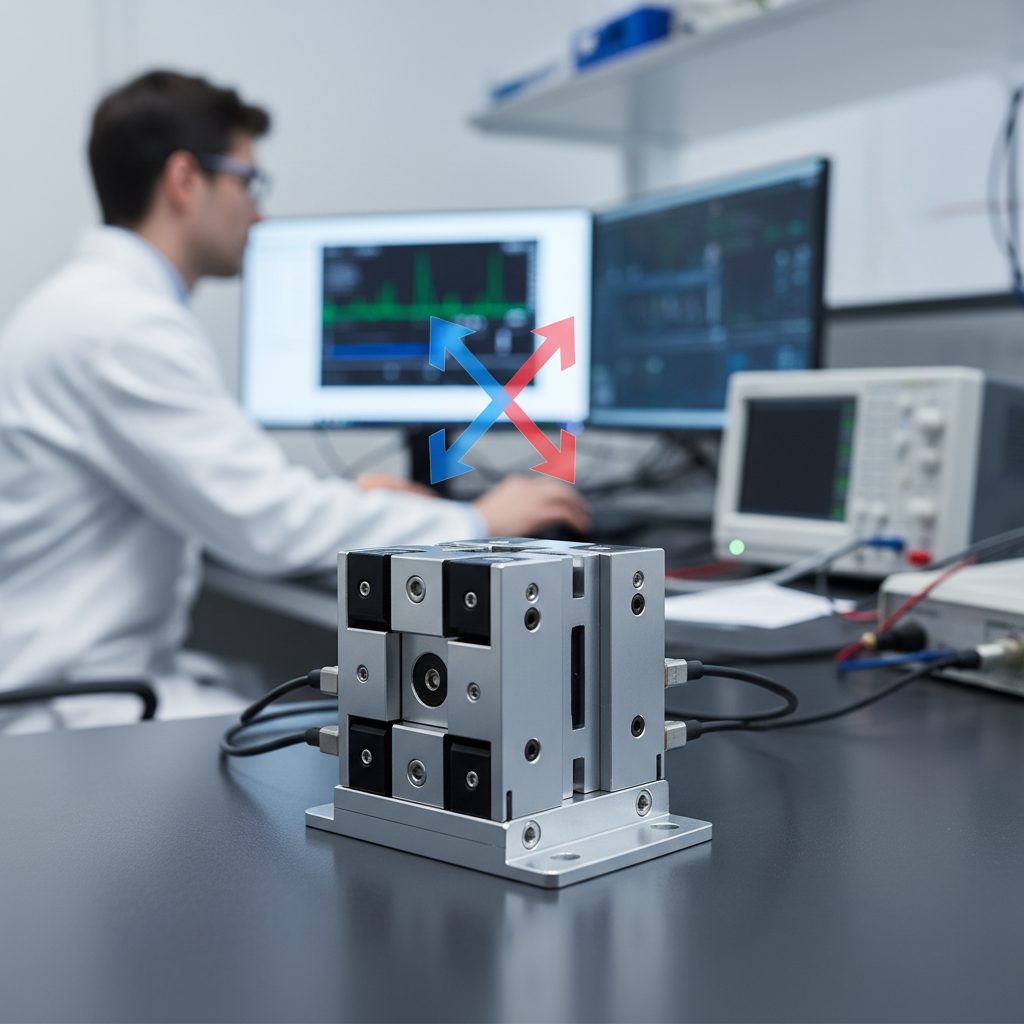

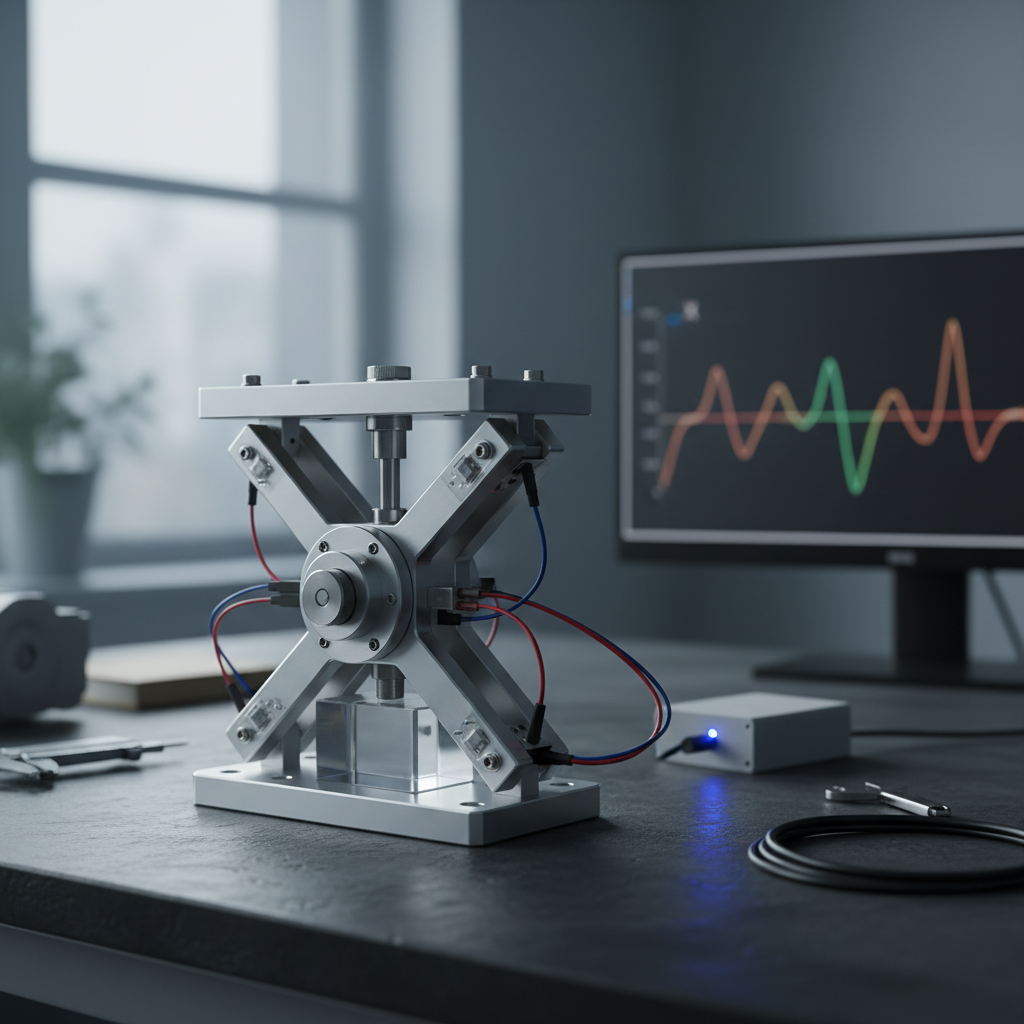

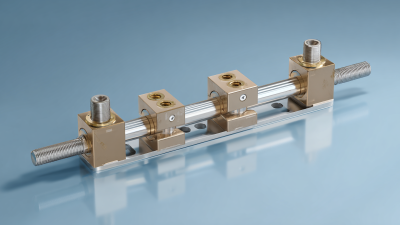

Biaxial load cells are essential components in a variety of applications where accurate measurement of force in two directions is required. These innovative devices allow for precise load measurements that can be crucial in fields ranging from material testing to biomedical engineering. Understanding the fundamental definitions and applications of biaxial load cells can greatly enhance their integration into experimental setups and manufacturing processes.

Recent advancements highlight the importance of biaxial load systems in the field of tissue engineering. A novel bioreactor system designed for biaxial mechanical loading has shown promising results in enhancing the properties of engineered human cartilage. By simulating the natural stress and strain experienced by cartilage in the body, these biaxial load cells aid in the development of autologous cartilage tissues, which have the potential to significantly improve clinical outcomes for patients suffering from joint disorders. This underscores the critical role biaxial load cells play not only in traditional industrial applications but also in groundbreaking medical research and therapies.

Key Specifications to Consider When Selecting a Biaxial Load Cell

When selecting a biaxial load cell for your application, understanding key specifications is essential for optimal performance. One of the most critical parameters to consider is the load capacity. Most biaxial load cells come with specified maximum loads that they can accurately measure. According to a report by the International Society of Automation, load cells need to handle overload conditions up to 150% of their rated capacity without failure. This makes it crucial to select a load cell that not only meets the maximum weight requirements of your application but also offers a safety margin for unexpected loads.

Another important factor is the accuracy class of the load cell. High-precision applications often require load cells with accuracies of 0.1% of full scale or better. For instance, a study published in the Journal of Measurement Science highlighted that for industries like aerospace and automotive testing, the highest accuracy ratings are paramount to ensure reliable data capture. Additionally, factors such as environmental considerations—including temperature and humidity ranges—should be evaluated. Ensuring that the load cell is rated for your specific environmental conditions can greatly enhance the longevity and reliability of your measurements.

Impact of Load Cell Accuracy on Measurement Reliability

Load cell accuracy is critical for the reliability of measurement systems, particularly in applications where precision is paramount. This is especially true in fields such as medical research, where accurate data is required to assess performance and monitor fatigue. For instance, in the analysis of performance tests like the countermovement jump (CMJ) and isometric mid-thigh pull (IMTP), the accuracy of load cells used to measure force output can significantly influence the results. Ensuring that the load cells maintain high accuracy under varying conditions can provide more reliable insights, particularly when comparing data across different subjects, such as in a sex-based analysis of elite athletes.

When selecting a load cell, considerations must also include its sensitivity to changes in load, which directly impacts measurement reliability. A load cell that is not finely tuned to detect small variations may lead to erroneous conclusions regarding athlete performance or rehabilitation progress. The integration of advanced technology, such as the mounting kits designed for easy installation while ensuring maximum accuracy and safety, is vital for achieving optimal performance. In light of these factors, prioritizing accuracy and precision in load cell selection is essential for achieving trustworthy results in any application requiring reliable force measurement.

Comparing Different Biaxial Load Cell Technologies and Their Benefits

When selecting the best biaxial load cell for your application, it's crucial to understand the varying technologies available and their specific benefits. Biaxial load cells can utilize different principles, including strain gauge technology and piezoelectric sensors, each offering unique advantages depending on the application scenario. For instance, strain gauge-based cells are highly sensitive and can measure static loads accurately, making them ideal for applications requiring precise measurement in low-load environments. In contrast, piezoelectric load cells excel in dynamic load applications, delivering quick response times, which are essential for monitoring sudden load changes.

Recent advancements in applications of biaxial load cells also highlight their integration in bioreactor systems designed for mechanical loading of tissue-engineered constructs. Such systems not only facilitate the enhancement of engineered cartilaginous tissues but also significantly improve the overall properties of the resulting constructs. The use of biaxial load cells in this context demonstrates their versatility, showcasing how they can provide the necessary precision and control required in bioengineering applications. By comparing these technologies, users can make informed decisions that align with their specific requirements, whether for industrial, research, or clinical applications.

2025 Biaxial Load Cell Technology Comparison

This chart compares the various types of biaxial load cells based on their key features and performance characteristics.

Real-World Applications of Biaxial Load Cells in Various Industries

Biaxial load cells are crucial components in various industries where accurate force measurement is required. In the field of robotics, for instance, these sensors can be used to ensure the precise balance and distribution of weight, enhancing the performance and safety of robotic arms in manufacturing processes. By measuring forces in two orthogonal directions, biaxial load cells allow engineers to optimize designs that require intricate handling of components, ensuring that the robotic systems operate within safe load limits.

In the realm of aerospace, biaxial load cells play a vital role in structural testing and material analysis. They enable engineers to measure the load and stress on aircraft components under various conditions, ensuring compliance with strict safety regulations. In addition, the automotive industry utilizes these load cells for crash testing and to evaluate the performance of suspension systems. By implementing biaxial load cells in these applications, manufacturers can make informed decisions about design improvements and material choices, ultimately leading to safer and more efficient vehicles.

2025 How to Choose the Best Biaxial Load Cell for Your Application - Real-World Applications of Biaxial Load Cells in Various Industries

| Industry | Application | Load Cell Type | Key Features | Calibration Range |

|---|---|---|---|---|

| Manufacturing | Material Testing | Biaxial Load Cell | High Precision, Compact Design | 0 to 2000 N |

| Aerospace | Structural Testing | Biaxial Load Cell | Durable, Temperature Resistant | 0 to 5000 N |

| Automotive | Crash Testing | Biaxial Load Cell | High Sensitivity, Shock Resistant | 0 to 10000 N |

| Civil Engineering | Load Bearing Tests | Biaxial Load Cell | Robust, Corrosion Resistant | 0 to 8000 N |

| Healthcare | Biomedical Testing | Biaxial Load Cell | Biocompatible, High Accuracy | 0 to 500 N |

Related Posts

-

Top Strategies for Selecting the Best 5kg Load Cell for Your Business Needs

-

How Rigging Load Cells are Revolutionizing Modern Weight Measurement in Construction

-

Navigating Industry Standards for Best Weight Transducer and Its Challenges

-

Ultimate Guide to Comparing the Top Weight Transducers for Global Buyers

-

Exploring the Future of Load Cells: Innovations Beyond the Best Bending Beam by 2025

-

What is a Thin Load Cell and How Does It Improve Measurement Accuracy?