sales@loadcellsensor.com

sales@loadcellsensor.com

How to Choose the Best Tension Compression Load Cell for Your Needs?

Choosing the right Tension Compression Load Cell can be daunting. These devices are crucial for many applications, including industrial weighing and force measurement. Their accuracy and reliability directly impact your operations.

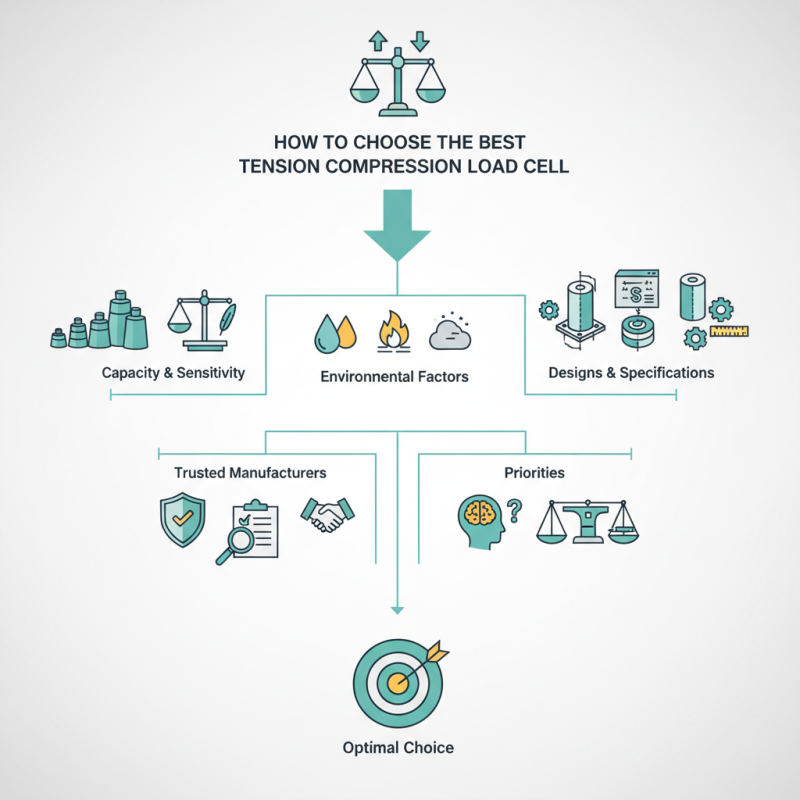

Consider the specific needs of your project. You must think about capacity, sensitivity, and environmental factors. A Tension Compression Load Cell may seem straightforward, but small differences matter. Familiarize yourself with various designs and specifications. Each option has unique benefits and potential drawbacks.

Look for trusted manufacturers, but remember that not all products meet the same standards. Some might promise performance but fall short in practice. It's essential to weigh the features against your requirements carefully. Do you prioritize precision or durability? Reflect on your priorities.

Understanding Tension Compression Load Cells: A Brief Overview

Tension compression load cells are essential devices in various industries. They measure force accurately by converting mechanical strain into an electrical signal. Generally, they consist of a metal body that deforms slightly under load, allowing for precise measurements.

These load cells come in different shapes and sizes, each designed for specific applications. Some are ideal for weighing, while others are suited for materials testing. Understanding the application is crucial. Choosing the wrong type can lead to inaccurate readings. Users should consider factors like load capacity and environmental conditions. Not all load cells perform well in extreme temperatures or humid environments.

Installation and calibration are also significant. Improper setup often leads to measurement errors. A poorly calibrated load cell can produce misleading data. Regular maintenance checks are necessary to ensure long-term reliability. Learning from past mistakes can help enhance future installations.

Key Factors to Consider When Selecting Load Cells

Choosing the right tension compression load cell can be challenging. It’s crucial to consider key factors like capacity and accuracy. These elements directly influence performance. Think about the maximum load you expect. A load cell with insufficient capacity will fail or give inaccurate readings. Accuracy is equally important; look for cells with a high level of precision.

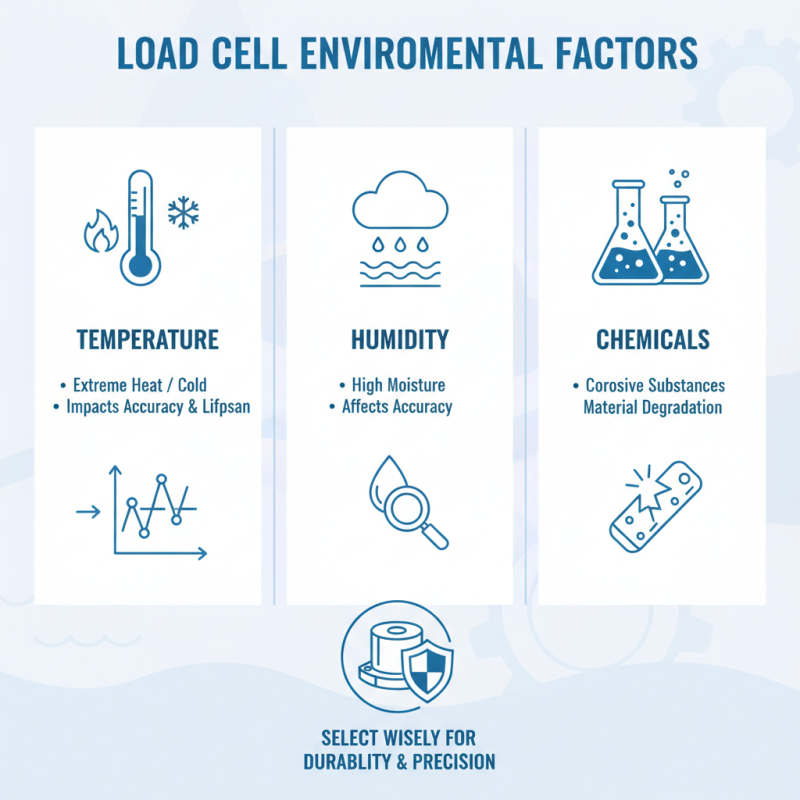

Next, consider environmental conditions. Will it be exposed to dust or moisture? If so, opt for a load cell with protective features. Temperature ranges matter too. Extreme conditions can affect readings. Connector types are another factor. Ensure compatibility with your existing systems. You don’t want to face unexpected integration issues.

Lastly, think about maintenance needs. Some load cells require regular calibrations. This process can be time-consuming. Reflect on how often you can perform maintenance tasks. If you are unsure, consult with experts. This can prevent costly mistakes down the line. No one wants to deal with a malfunctioning load cell in critical applications.

Assessing Your Specific Application Requirements

Choosing the right tension compression load cell begins with understanding your specific application. Different industries demand varying load capacities, sensitivity, and environmental resistance. For example, the automotive sector often requires cells that can measure forces up to 200,000 pounds. In contrast, medical applications may only need measurements in the range of a few thousand pounds. Evaluating your needs can save money and time.

Tip: Always consider the load cell's environment. Will it be exposed to moisture or high temperatures? Look for load cells with IP ratings suitable for your conditions.

Another aspect to reflect on is the expected accuracy. Many applications demand a precision of ±0.1% or better. However, some users might find they can operate effectively within ±1%. This realization could lead to cost savings by selecting less expensive load cells that still meet required metrics.

Tip: Test load cells under actual working conditions to understand their performance. This helps in making informed decisions.

Comparing Load Cell Accuracy, Capacity, and Sensitivity

When choosing a tension compression load cell, accuracy, capacity, and sensitivity are key factors. Accuracy indicates how close a measurement is to the actual value. A load cell's precision can greatly impact the results you get. Look for specifications that detail this aspect. It's also important to test the load cell in real-world scenarios. Sometimes, datasheets may not reflect on-site performance.

Capacity refers to the maximum load a cell can handle. It's crucial to select a load cell that meets your specific needs. Overloading a load cell can lead to inaccurate readings or damage. Always consider future needs, too. A slightly higher capacity may save you from needing a replacement.

Sensitivity affects how effectively a load cell can detect small changes in load. Higher sensitivity means better performance in tasks requiring fine measurements. You may find that certain scales just don’t measure small increments well. Test various models to find the right fit for your application.

**Tips:** Always calibrate your load cell regularly. This ensures accuracy over time. Also, keep an eye on environmental factors that might affect performance. Things like temperature and humidity play a significant role.

Load Cell Accuracy, Capacity, and Sensitivity Comparison

Evaluating Environmental Conditions and Installation Constraints

When selecting a tension compression load cell, it's crucial to evaluate environmental conditions. Humidity, temperature, and exposure to chemicals must be considered. For instance, a load cell in a coastal environment faces different challenges compared to one in a controlled indoors setting. High humidity levels can impact accuracy. Similarly, extreme temperatures may affect the load cell's lifespan.

Installation constraints also play a vital role. Space limitations might restrict your choice of load cell. If the load cell cannot fit into the designated area, it can't function as needed. Consider the orientation and mounting method as well. Some designs require specific angles for accurate readings. If installation is not optimal, you may face unexpected issues later.

Don't forget about vibration and shock in your workspace. In some applications, such as industrial settings, moving machinery creates excessive vibrations. A load cell sensitive to these can lead to errors. Reflecting on these factors can help ensure a more reliable setup. Make adjustments based on the specific requirements of your environment.

Related Posts

-

Global Sourcing Revolution: How China's Best Thin Load Cells Set the Standard for Quality and Reliability

-

Top 5 Micro Load Cells for Accurate Measurement in Industrial Applications

-

Unlocking Success with Thin Load Cells Effective Ways to Identify Quality Suppliers

-

Top Strategies for Enhancing Accuracy with Miniature Load Cells

-

Top Applications of Donut Load Cells in 2025 You Should Know About

-

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements