sales@loadcellsensor.com

sales@loadcellsensor.com

How to Choose Load Cell Sensors for Accurate Measurements?

Choosing the right Load Cell Sensor is crucial for achieving precise measurements. These sensors play a vital role in various industries, from manufacturing to laboratory settings. Understanding their specifications ensures accurate data collection and performance.

When selecting a Load Cell Sensor, factors such as capacity, accuracy, and environmental conditions must be considered. Each sensor type offers unique benefits. However, with so many options, the choice can be overwhelming. It’s important to identify the application requirements upfront. This clarity helps eliminate options that don't fit.

Some users may overlook key specifications, leading to suboptimal performance. That's a risk not worth taking. Measuring capabilities can differ significantly between models. Therefore, reflecting on your specific needs is essential. A poorly selected Load Cell Sensor can result in inaccurate results, affecting overall outcomes. Each decision matters in achieving reliability and efficiency.

Understanding Load Cell Sensors and Their Applications

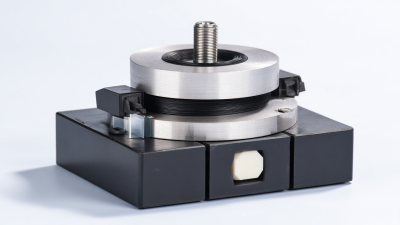

Load cell sensors play a crucial role in various applications, from industrial scales to medical devices. They convert force or weight into an electrical signal, ensuring accurate measurements. According to a recent industry report, the global load cell market is expected to reach $3.9 billion by 2026, driven by the demand for precision in weight measurement and automation.

Choosing the right load cell sensor can be challenging. Understanding your application is essential. Different types, such as strain gauge, pneumatic, and hydraulic load cells, serve specific needs. For instance, strain gauge load cells are popular due to their accuracy and affordability. They can measure weights ranging from grams to tons. However, they might not perform well in extreme temperature conditions.

Tip: Always consider environmental factors. Humidity and temperature can affect load cell performance. Calibration is key to maintaining accuracy. Regular checks can prevent costly errors.

When selecting a load cell, also think about capacity and sensitivity. Oversized load cells may lead to underperformance. On the other hand, undersized ones might overload easily. Striking the right balance is critical to achieving reliable measurements. Load cells must match application requirements closely. Small miscalculations can lead to significant inaccuracies, affecting productivity and safety.

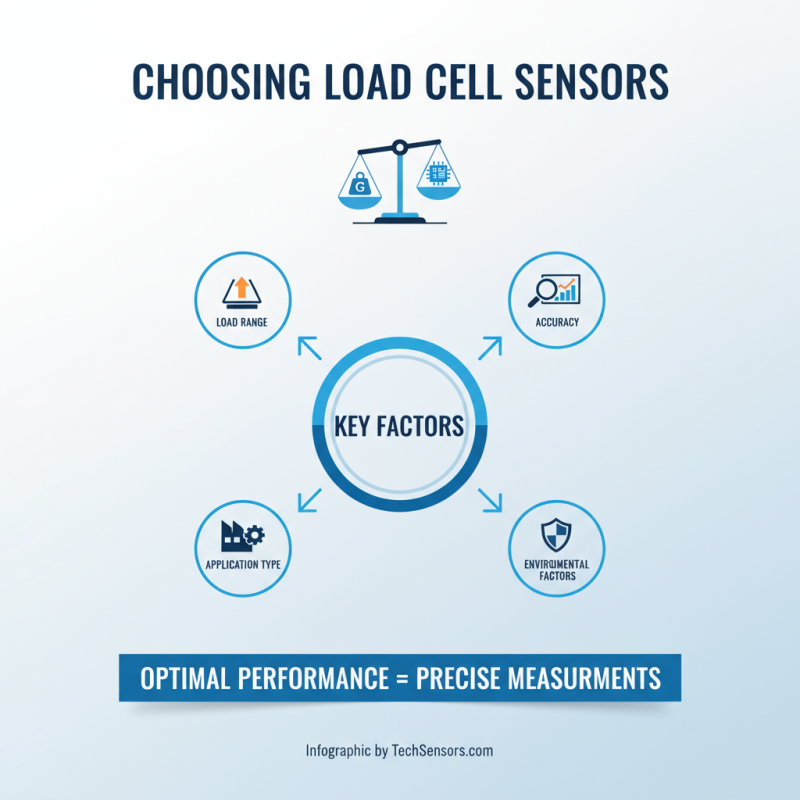

Key Factors to Consider When Selecting Load Cell Sensors

Choosing the right load cell sensors is crucial for achieving accurate measurements. There are several key factors to consider. One of the most important is the load range. Load cells can handle varying weights, and selecting one with an appropriate range ensures optimal performance. For instance, a load cell with a full-scale range that matches your application can enhance accuracy by reducing measurement errors.

Sensitivity also plays a significant role. It defines how much the output signal changes with a change in load. A high sensitivity load cell can detect small weight changes, which is vital in applications requiring fine measurements. According to recent industry studies, a sensor with a sensitivity of 2 mV/V is typically reliable for precision tasks.

Environmental conditions cannot be overlooked. Load cells need to function effectively under specific temperatures and humidity levels. Additionally, factors like vibration or shock can affect performance. For outdoor applications, using cells with proper weatherproofing is essential. Sometimes, people fail to account for these conditions, leading to measurement inaccuracies. Thoughtful consideration of these factors can differentiate between precise and flawed readings in load measurement systems.

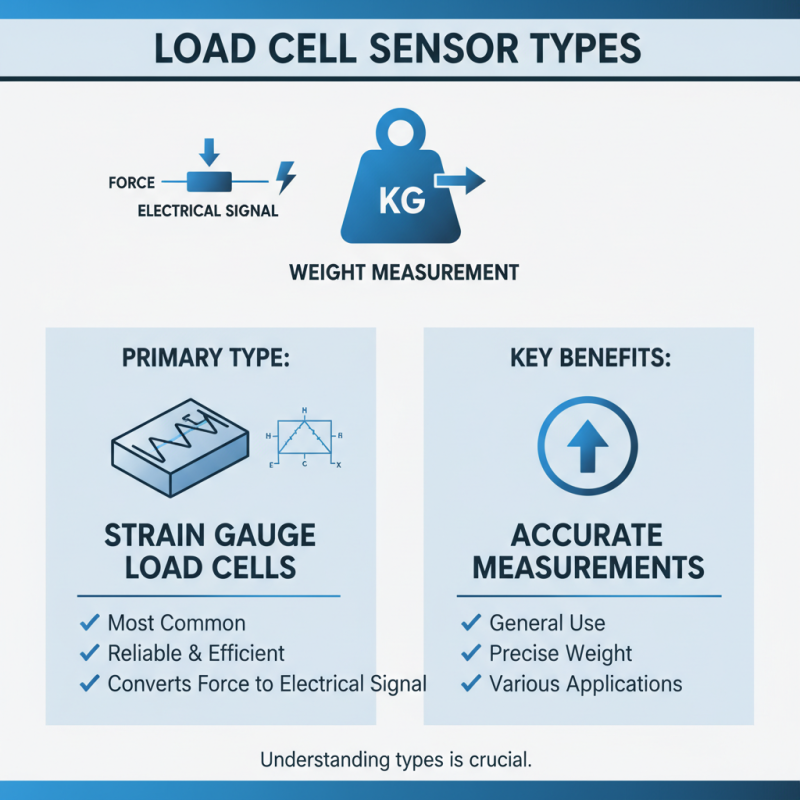

Types of Load Cell Sensors and Their Measurement Capabilities

When selecting load cell sensors, understanding their types is crucial for accurate measurements. Load cells come in various forms, each designed for specific applications. Strain gauge load cells are the most common. They are reliable and efficient for general use. These load cells convert force into an electrical signal. They can measure weight precisely.

Another type is the hydraulic load cell. This one relies on fluid pressure to gauge the load. It suits heavy-duty applications, such as truck scales. However, these can be complex to install. Choosing between them can be challenging. If you require high precision, consider pneumatic load cells. They use compressed air and excel in dynamic measurements. Yet, their sensitivity to environmental factors may raise concerns.

Understanding how these load cells function is essential. Each has strengths and weaknesses. Strain gauge sensors may not perform well under extreme conditions. Hydraulic sensors might struggle with small loads. Knowing each type's limitations helps in making informed decisions. Balancing requirements with capabilities can be tougher than expected. It’s a process of trial and error.

Importance of Calibration and Accuracy in Load Cell Selection

When selecting load cell sensors, calibration and accuracy are paramount. A recent industry report indicated that improper calibration can lead to measurement errors exceeding 5%. This level of inaccuracy can cause costly setbacks in industrial applications. Regular calibration ensures that load cells perform at their best, enhancing reliability.

Focusing on the specific needs of your application is vital. Different environments can affect sensor performance. For instance, temperature fluctuations may impact measurements. It's essential to choose load cells rated for the operational conditions they will face. Consider environmental factors during selection.

Tips: Regularly check calibration to maintain accuracy. Use a standardized procedure for calibration to ensure consistency. Monitor load cells frequently to spot any irregularities early. This proactive approach can prevent major issues down the line, ensuring sustained accuracy and reliability in measurements.

How to Choose Load Cell Sensors for Accurate Measurements? - Importance of Calibration and Accuracy in Load Cell Selection

| Load Cell Type | Capacity (kg) | Accuracy (%) | Calibration Method | Recommended Application |

|---|---|---|---|---|

| Strain Gauge | 100 | 0.03 | Static Calibration | Industrial Weighing |

| Load Cell Beam | 300 | 0.05 | Dynamic Calibration | Material Testing |

| Single Point | 500 | 0.02 | Load Cell Calibration | Retail Scales |

| Compression | 1000 | 0.1 | Pressure Calibration | Structural Testing |

| Tension/Compression | 2000 | 0.05 | Multi-point Calibration | Research & Development |

Environmental Considerations for Load Cell Sensor Usage

When selecting load cell sensors, environmental factors play a crucial role. Temperature fluctuations can affect accuracy. High humidity may lead to corrosion, impacting sensor life. It’s essential to consider the operating conditions. Is the sensor placed outdoors or indoors? If outdoors, what protection is needed?

Dust and vibration are also significant. In a manufacturing setting, vibration can cause disturbances. Ensuring load cells are vibration-resistant helps maintain performance. Dust exposure may require additional housing. Using enclosures can provide extra protection without sacrificing accuracy.

Finally, consider the installation location. Proximity to other machinery can introduce interference. It’s vital to keep sensors away from obstructive elements. Reflections or ambient light can confuse readings. The context of where the sensor is placed ultimately influences its effectiveness. Evaluate these factors thoroughly for improved measurement accuracy.

Related Posts

-

Top Applications of Donut Load Cells in 2025 You Should Know About

-

The Ultimate Guide to Sourcing High-Quality Suppliers for Best Button Type Load Cells

-

Top Load Cell Types and Their Applications in Industrial Weighing Systems

-

Top 5 Micro Load Cells for Accurate Measurement in Industrial Applications

-

5 Essential Tips for Choosing the Right Tension Compression Load Cell

-

Unlocking Success with Thin Load Cells Effective Ways to Identify Quality Suppliers