sales@loadcellsensor.com

sales@loadcellsensor.com

How to Choose the Right Load Cell 2kg for Accurate Measurements

Selecting the appropriate Load Cell 2kg for precise measurements is a critical step in ensuring accuracy in various applications, from industrial weighing systems to laboratory research. With the proliferation of different load cell types and specifications in the market, it can be overwhelming for users to determine which model best suits their needs. Expert load cell engineer Dr. Emily Carter emphasizes this challenge, stating, "Choosing the right Load Cell 2kg is fundamental, as even minor discrepancies can lead to significant errors in measurement outcomes."

In many industries where precision is paramount, such as manufacturing and quality control, the ability to select the correct load cell can significantly influence operational efficiency and product integrity. Understanding the various factors that affect load cell performance—including sensitivity, environmental conditions, and mounting options—can make all the difference. This article aims to guide you through the essential considerations to bear in mind when selecting a Load Cell 2kg, ensuring that your measurements are accurate and reliable.

Factors to Consider When Selecting a 2kg Load Cell

When selecting a 2kg load cell for precise measurements, several critical factors must be considered to ensure accuracy and reliability. First and foremost is the load cell's operating range and capacity. Choosing a load cell with an appropriate range is essential; selecting one that exceeds the maximum expected load can yield significant measurement errors. According to industry reports, the best practice is to select a load cell with a capacity approximately 1.5 to 2 times greater than the maximum load to be measured, which helps mitigate risks associated with overload and enhances longevity and stability.

Another important factor is the load cell's sensitivity and accuracy specifications. Sensitivity, often stated in millivolts per volt (mV/V), is a key indicator of how much output the load cell provides per unit of input. A higher sensitivity ensures better resolution in measurements. Reports show that high-precision load cells, which have sensitivity values of 2 mV/V or higher, significantly improve the reliability of measurements in scientific applications. Additionally, consider the environmental conditions in which the load cell will operate, such as temperature, humidity, and potential exposure to corrosive substances. Load cells designed with specific environmental protections can drastically reduce measurement errors caused by external factors, thereby improving overall measurement integrity.

Load Cell Selection Factors

Types of 2kg Load Cells and Their Applications

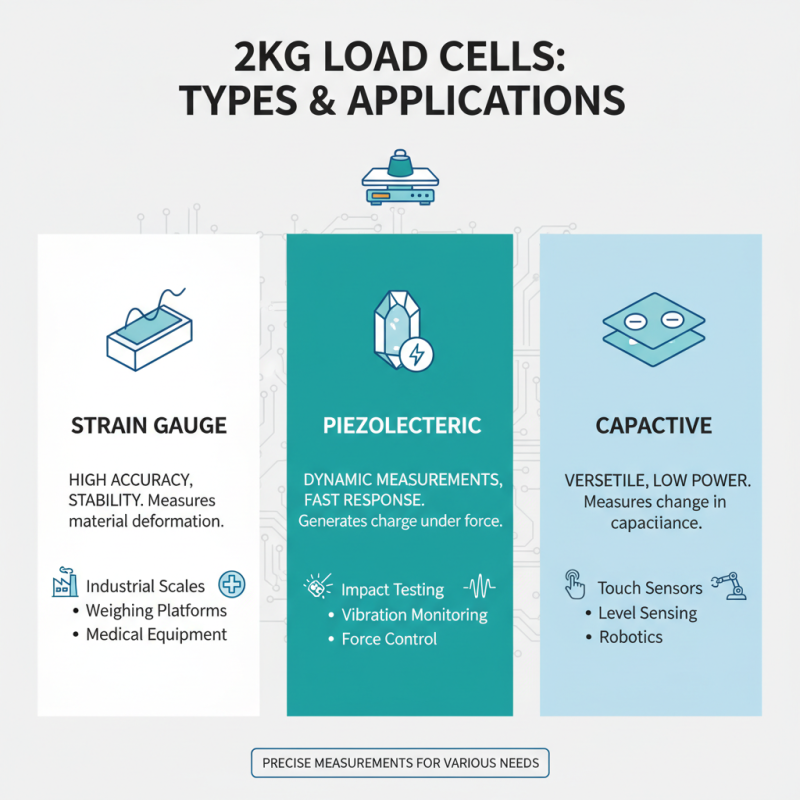

When selecting a 2kg load cell, understanding the different types and their applications is essential for achieving precise measurements. The most common types include strain gauge load cells, piezoelectric load cells, and capacitive load cells. Strain gauge load cells are widely used due to their high accuracy and stability. They operate on the principle of measuring the deformation of a material when a load is applied, making them suitable for various applications such as industrial scales, weighing platforms, and medical equipment.

Piezoelectric load cells, on the other hand, are designed for dynamic measurements and are commonly used in applications involving rapid changes in load, such as force testing and impact measurements. These load cells generate an electric charge in response to applied pressure, providing high sensitivity for dynamic forces. Capacitive load cells are ideal for applications requiring less sensitivity to temperature changes and are often used in agriculture and food processing industries where consistent and accurate measurements are critical for maintaining quality control. Understanding these types helps ensure you choose the right load cell for your specific measurement needs and enhances the accuracy of your results.

Understanding Precision and Accuracy in Load Cells

Precision and

accuracy are

crucial factors when selecting a load cell for applications requiring precise weight measurements.

Understanding the difference between these two terms is essential for making an informed choice.

Precision refers to the consistency of measurements taken

under the same conditions over time. A load cell can be highly precise, consistently delivering similar

results, even if those results are not close to the actual weight being measured. Therefore, it is

important to consider the precision rating of the load cell to ensure that repeated measurements will

yield reliable results.

On the other hand, accuracy reflects how close a measured

value is to the true value of the weight being assessed. A load cell that is accurate will provide

measurements that are in alignment with the actual weight, minimizing errors. When choosing a load cell,

one must pay attention to its accuracy specifications, such as the percentage of full-scale output error.

A load cell that boasts high accuracy and precision

will provide users with confidence that the measurements being recorded are both consistent and

reliable, which is essential in applications ranging from industrial weighing to scientific research.

Understanding these concepts can significantly impact the effectiveness of measurements and outcomes

in various fields.

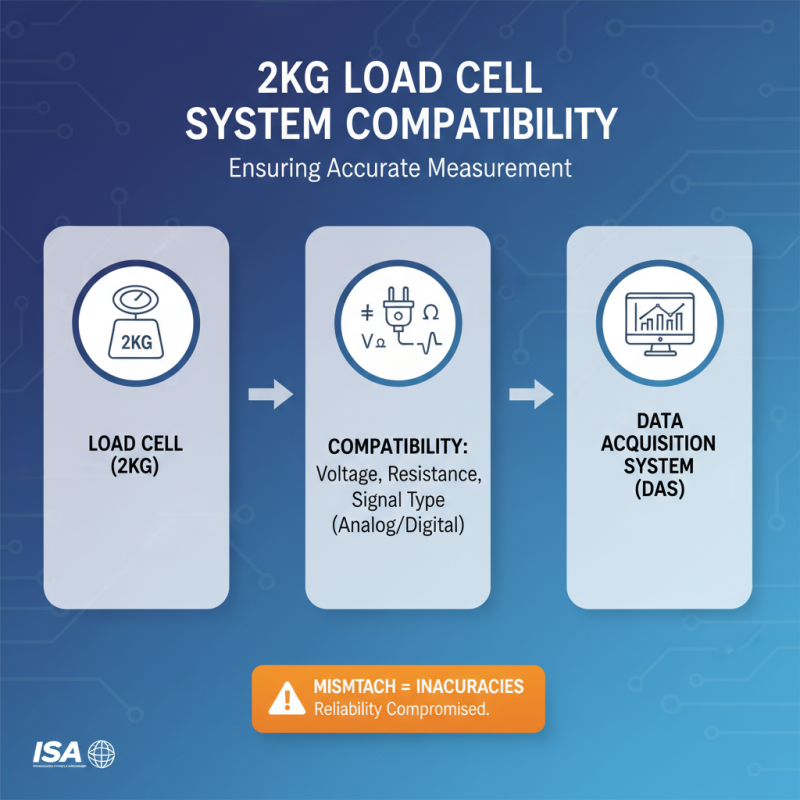

Compatibility: Integrating Load Cells with Measurement Systems

When integrating a 2kg load cell into measurement systems, compatibility is paramount. Load cells need to be compatible with the rest of the measurement system to ensure accurate data collection and interpretation. According to a report by the International Society of Automation, measurement inaccuracies can arise from mismatched specifications, such as voltage, resistance, and signal output types. For instance, a load cell’s output needs to be compatible with the analog or digital input specifications of the connected data acquisition system. Failure to align these components can lead to significant measurement errors, compromising the reliability of the data collected.

Moreover, the environmental compatibility of the load cell should also be considered. Many applications require operation in challenging conditions, such as high humidity or extreme temperatures. A study from the Journal of Measurement Science highlighted that approximately 15% of load cell failures are attributed to environmental factors, which underscores the necessity of selecting a load cell that not only meets the required capacity but also is rated for the specific conditions where it will be used. Ensuring that the load cell can withstand the operational environment will contribute to the longevity and accuracy of the measurement system, thus enhancing overall performance.

Installation and Calibration Tips for 2kg Load Cells

When installing a 2kg load cell, proper alignment and secure mounting are crucial for achieving accurate measurements. Begin by ensuring that the load cell is positioned perfectly in line with the load application to prevent any sideways forces that could affect its performance. Use appropriate mounting hardware to ensure that the load cell is firmly attached, minimizing any potential movement during operation. Additionally, verify the installation environment to ensure it is stable, dry, and free from excessive vibrations or temperature fluctuations, as these factors can interfere with the load cell's readings.

Calibration of the load cell is the next critical step to ensure precision. Start by applying known weights to the load cell and recording the output readings. It is essential to apply weights that are close to the load cell's nominal value (in this case, 2kg) to ensure accuracy over its operational range. After collecting data, use this to create a calibration curve or adjust the output using calibration settings available in your measuring instrument. Regular checking and recalibration should also be part of a routine maintenance plan to ensure continued precision in your measurements. This proactive approach will help you maintain the reliability of your load cell under varying operational conditions.

Related Posts

-

2025 Top 10 Load Cell 2kg Models for Precision Weighing: Expert Reviews and Comparisons

-

5 Essential Tips for Choosing the Right Thin Load Cell

-

Unlocking Success with Thin Load Cells Effective Ways to Identify Quality Suppliers

-

How to Choose the Best Low Profile Load Cell for Your Application

-

12 Expert Tips for Maximizing Efficiency with Compression Force Sensors

-

Ultimate Checklist for Choosing the Best Compression Type Load Cell for Your Business Needs