sales@loadcellsensor.com

sales@loadcellsensor.com

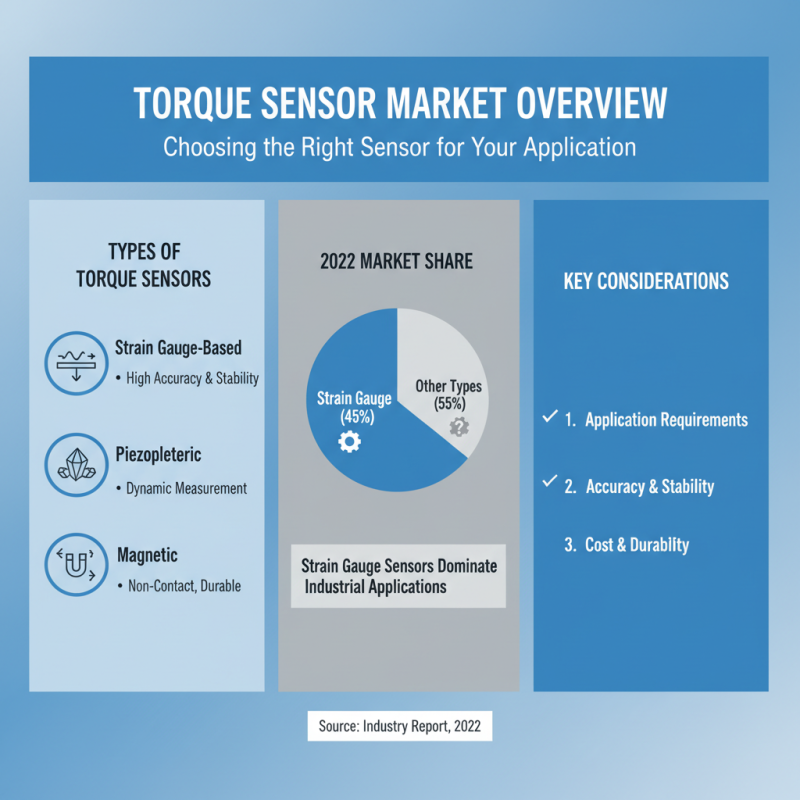

How to Choose the Right Torque Sensor for Your Applications

Choosing the right torque sensor for your applications is a critical decision that can significantly impact the performance and accuracy of your projects. Torque sensors play a vital role in various industries, including automotive, aerospace, robotics, and manufacturing, where precise torque measurement is essential for ensuring optimal functioning and safety. With advancements in technology, there are numerous types of torque sensors available, each designed to meet specific requirements and operational conditions.

When selecting a torque sensor, it's important to consider factors such as the measurement range, accuracy, response time, and environmental conditions. Understanding your application's unique demands will guide you in determining which sensor type is best suited to your needs. Additionally, aspects such as installation compatibility and integration with existing systems should not be overlooked, as they can greatly influence the efficacy of the torque sensor in real-world applications.

Ultimately, the right torque sensor can enhance productivity, reliability, and overall efficiency in your operations. By carefully evaluating your requirements and exploring various options, you can make an informed choice that aligns with your goals and ensures successful outcomes in torque measurement tasks.

Understanding Torque Sensor Basics and Their Applications

Torque sensors are essential devices used to measure the rotational force applied to an object, which makes them invaluable in various applications across industries such as automotive, aerospace, and manufacturing. Understanding the fundamental principles of torque sensing is crucial for selecting the right sensor for specific needs. At their core, these sensors operate by converting mechanical torque into an electrical signal. This is typically achieved through strain gauges or other sensing technologies that detect the deformation of a material under load.

The applications of torque sensors are diverse, ranging from monitoring engine performance in vehicles to ensuring precision in automated assembly lines. In automotive testing, torque sensors help engineers understand the efficiency and performance of engines and drivetrains. In manufacturing, they assist in verifying that machinery operates within specified torque limits, thereby preventing damage and ensuring product quality. Choosing the right torque sensor requires a consideration of factors such as measurement range, accuracy, and environmental conditions, ensuring optimal performance for the intended application.

Identifying Key Specifications for Your Torque Sensor Needs

When selecting a torque sensor, understanding the key specifications that align with your application is crucial. First and foremost, consider the torque range required for your measurements. Reports suggest that understanding the operational torque range can significantly enhance measurement accuracy. For instance, in applications involving automotive testing, a typical torque range may vary from 1 Nm to 1000 Nm, necessitating sensors that can handle both low and high torque values without compromising performance.

Another critical specification is the sensor's sensitivity and accuracy. The sensitivity dictates the smallest torque change the sensor can detect, while accuracy defines how close the measured values are to the actual torque. Industry data indicate that high-precision applications often require torque sensors with an accuracy of better than ±0.5% of full scale. This level of precision is essential in sectors such as aerospace and medical device manufacturing, where even the slightest deviation can have significant consequences.

Finally, the environmental conditions where the sensor will be used also play a pivotal role. Factors such as temperature, humidity, and exposure to harmful chemicals can affect the sensor's performance. Reports highlight that torque sensors built with robust protective features can last longer in harsh environments, thus reducing maintenance costs and downtime. By carefully evaluating these specifications, you can ensure that the torque sensor you choose is well-suited for your specific application needs.

Torque Sensor Specifications Comparison

This chart compares various torque sensor models based on their rated capacity (in Nm) and accuracy (as a percentage). It helps users identify which torque sensor may best fit their application requirements.

Evaluating Different Types of Torque Sensors Available

When evaluating different types of torque sensors available in the market, it is essential to consider the specific requirements of your application. Torque sensors can be classified into various categories, including strain gauge-based sensors, piezoelectric sensors, and magnetic sensors. Each type offers its unique advantages; for example, strain gauge sensors are known for their accuracy and stability, making them suitable for applications that require precise torque measurement. According to a recent industry report, strain gauge torque sensors accounted for over 45% of the market share in 2022, highlighting their predominance in industrial applications.

On the other hand, piezoelectric sensors are preferred for dynamic torque measurements due to their ability to respond quickly to changing conditions. This characteristic is vital in high-speed applications, where traditional sensors might not provide real-time data. A study by a leading market analysis firm predicted that the demand for piezoelectric torque sensors would grow by 7.5% annually through 2025, driven by advancements in automotive testing and aerospace applications. Lastly, magnetic sensors, while less common, offer robust performance in harsh environments, making them ideal for heavy machinery and industrial processes. Each of these sensor types plays a critical role in ensuring accurate torque measurement across various sectors, and choosing the right one depends on a detailed assessment of operational demands and environmental conditions.

Assessing Environmental Factors for Sensor Selection

When selecting a torque sensor for specific applications, it is crucial to consider various environmental factors that may influence the sensor’s performance and longevity. The operating temperature range is one primary factor; extreme temperatures can affect a sensor’s accuracy and responsiveness. Additionally, humidity levels can lead to corrosion or other forms of damage if the sensor is not adequately protected. It becomes essential to evaluate the sensor’s materials and sealing capabilities to ensure they can withstand the environmental conditions, such as exposure to moisture, dust, or chemical substances.

Another significant consideration is the potential for vibration or shock in the application environment. Sensors that will be subjected to high levels of dynamic forces require robust construction to maintain their integrity and provide accurate data. Furthermore, electromagnetic interference might pose challenges in certain settings, necessitating the choice of sensors with shielding capabilities. Ultimately, a comprehensive assessment of these environmental factors will guide users towards selecting the most suitable torque sensor, ensuring optimal performance and durability in their specific applications.

Analyzing Cost-Effectiveness and Support Options for Sensors

When selecting a torque sensor for your specific applications, analyzing cost-effectiveness is crucial in ensuring that the sensor meets both budgetary constraints and performance expectations. Cost-effectiveness is not solely about the initial price of the sensor; it also encompasses factors such as maintenance costs, calibration requirements, and the longevity of the sensor. A more expensive sensor might provide superior accuracy and durability, ultimately resulting in reduced long-term costs associated with replacements or downtime in operations. Therefore, conducting a comprehensive cost analysis that factors in the total lifecycle of the sensor can guide you toward making a financially sound decision.

In addition to cost-effectiveness, evaluating the support options available for the torque sensor is essential for ensuring optimal performance in the long run. Look for manufacturers that offer extensive technical support, including installation assistance, troubleshooting, and maintenance services. Access to knowledgeable customer service representatives can significantly minimize production disruptions and improve the overall productivity of your operations. Furthermore, understanding the availability of warranty options and ongoing support is fundamental, as these can provide peace of mind and added security for your investment. This holistic approach to choosing the right torque sensor will empower you to not only select the most suitable product but also to maximize its potential in your applications.

How to Choose the Right Torque Sensor for Your Applications - Analyzing Cost-Effectiveness and Support Options for Sensors

| Sensor Type | Cost ($) | Accuracy (%) | Max Torque (Nm) | Support Options |

|---|---|---|---|---|

| Strain Gauge Torque Sensor | 200 | 1.5 | 50 | Email, Phone Support |

| Rotary Torque Sensor | 350 | 0.5 | 100 | Online Chat, On-Site Support |

| Wireless Torque Sensor | 600 | 2.0 | 75 | Email, Phone, Online Tutorials |

| Capacitive Torque Sensor | 450 | 0.8 | 125 | Live Webinars, Email Support |

| Hall Effect Torque Sensor | 300 | 1.0 | 60 | Phone, Email, Comprehensive Documentation |

Related Posts

-

Maximizing Precision: Key Techniques for Effective Torque Sensor Implementation

-

Understanding the Basics of Torque Sensor Functionality and Applications

-

Navigating the Global Standards for Best Torque Sensor Imports and Exports

-

Exploring Innovative Torque Sensor Types: Real-World Applications and Benefits

-

How to Select the Right Torque Sensor for Enhanced Precision in Industrial Applications

-

Leading Factory in China Innovating Torque Transducers for Global Markets