sales@loadcellsensor.com

sales@loadcellsensor.com

Why Choose a 3-Axis Force Sensor for Your Projects?

In the world of engineering and product design, precision matters. A 3-Axis Force Sensor can provide crucial data for a variety of applications. According to the market research report from Grand View Research, the force sensors market is projected to reach $4.65 billion by 2025. This growth reflects the increasing demand for accurate force measurements across industries like robotics, automotive, and healthcare.

Choosing the right sensor can be challenging. A 3-Axis Force Sensor measures forces in three dimensions. This capability allows for better assessment of complex interactions in systems, contributing to improved designs. For instance, in robotic applications, integrating a 3-Axis Force Sensor can enhance feedback and control, leading to more agile and responsive machines.

Despite the advantages, some projects may require careful evaluation. Not every application benefits equally from a 3-Axis Force Sensor. The cost can be a significant factor for small businesses. Additionally, developers must consider how well the sensor integrates with current systems. Hence, understanding project requirements is essential before choosing the right sensor.

Understanding the Basics of 3-Axis Force Sensors

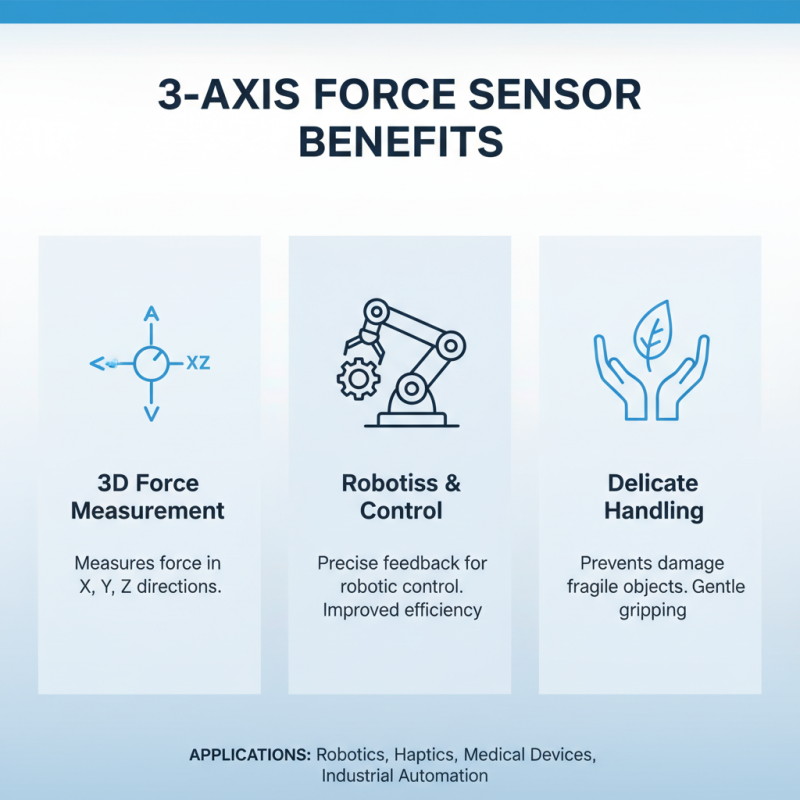

3-axis force sensors measure forces in three dimensions: X, Y, and Z. They are crucial in various applications, including robotics and biomechanics. By understanding how these sensors work, designers can make informed choices for their projects.

One intriguing aspect of a 3-axis force sensor is its ability to capture complex interactions. For instance, in a robotic arm, it accurately detects how much force is applied when gripping an object. This feedback is essential for delicate tasks, such as assembling electronics. However, users often overlook calibration. Improper calibration can lead to inaccurate readings.

Integrating 3-axis sensors in your projects can enhance performance. Yet, challenges arise. Environmental factors like temperature can affect sensor accuracy. Additionally, their design may be susceptible to noise, complicating data collection. Reflecting on these potential pitfalls is vital for successful implementation.

Key Advantages of Using 3-Axis Force Sensors in Various Applications

3-axis force sensors offer numerous advantages across various applications. They measure force in three dimensions: X, Y, and Z. This capability allows for precise feedback in robotics, ensuring better control and efficiency. For instance, in a robotic arm, the sensor can detect how much pressure is applied while gripping objects. It helps prevent damage to fragile items.

These sensors are also vital in biomechanics. They assist in analyzing human movements. By measuring forces during activities like walking or running, they provide crucial data. This data can help improve athletic performance or aid in rehabilitation. However, integrating these sensors into existing systems can be challenging. The calibration process requires meticulous attention and the right expertise.

Moreover, 3-axis force sensors find their place in manufacturing. They can detect anomalies in machinery. Identifying excessive force can prevent equipment failure and enhance safety. Yet, they need regular maintenance. Neglecting this can lead to inaccurate readings over time. Overall, the benefits are significant, but they necessitate careful implementation.

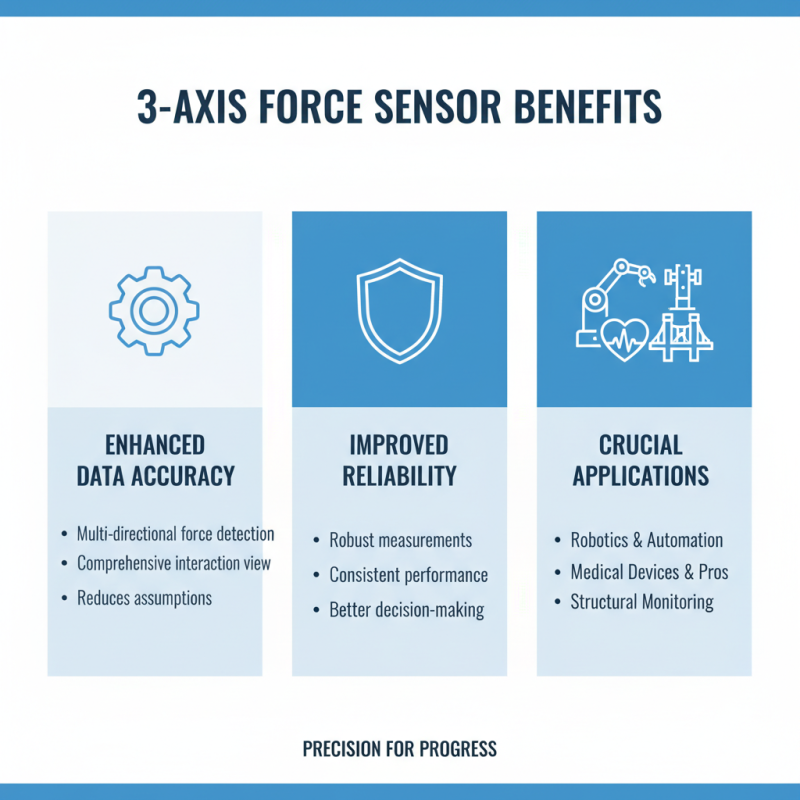

How 3-Axis Force Sensors Enhance Data Accuracy and Reliability

3-axis force sensors offer substantial benefits for enhancing data accuracy and reliability in various applications. These sensors detect forces in three different directions, providing a comprehensive view of interactions. This multi-dimensional capability is crucial in fields like robotics, medical devices, and structural monitoring. With precise measurements, engineers can make informed decisions based on concrete data, rather than assumptions.

Using a 3-axis force sensor can sometimes lead to unexpected challenges. Calibration issues might arise, affecting accuracy initially. Regular maintenance is essential to ensure optimal performance. Additionally, users may overlook the importance of the sensor's placement. An inappropriate position can skew results, which may require users to rethink their setup. Despite these potential setbacks, the benefits of enhanced data collection outweigh the difficulties. The insights gained can lead to significant improvements in project outcomes.

Common Applications and Use Cases for 3-Axis Force Sensors

3-axis force sensors are incredibly versatile tools, utilized in various applications across different fields. In robotics, they help enhance object manipulation. These sensors measure force in three directions, allowing robots to grip and release items with precision. In industrial automation, they are essential for quality control. They can detect anomalies in production lines, ensuring products meet specific standards.

Another area where 3-axis force sensors shine is in medical devices. They can provide feedback for prosthetics, enabling more natural movement. This can significantly improve the user experience. In research, they are invaluable for biomechanical studies. They help scientists understand how forces interact with the human body. Yet, implementing these sensors isn't always straightforward. Calibration and integration can present challenges. Users must be attentive to these aspects to ensure accurate data.

Why Choose a 3-Axis Force Sensor for Your Projects?

| Application | Use Case | Benefits |

|---|---|---|

| Robotics | Force feedback in robotic arms | Increased precision and control |

| Medical Devices | Surgical tools with haptic feedback | Enhanced surgeon safety and efficiency |

| Consumer Electronics | Touchscreen devices with pressure sensitivity | Improved user experience |

| Aerospace Engineering | Load monitoring on aircraft structures | Increased safety and compliance |

| Industrial Automation | Material handling and force detection | Reduced risk of equipment damage |

Selecting the Right 3-Axis Force Sensor for Your Project Needs

Choosing the right 3-axis force sensor requires careful consideration of your project's specific needs. Whether you are working on robotics, medical devices, or research, these sensors provide critical data. They measure forces accurately in three dimensions, making them versatile for various applications.

When selecting a sensor, consider the force range and sensitivity. Some projects need high precision, while others can operate with less accuracy. This variability often leads to a dilemma: do you choose a more expensive, high-precision sensor or a cost-effective solution?

Another aspect to ponder is installation. Some sensors are easy to integrate, while others may require complex setups. This can lead to delays in project timelines. It’s essential to evaluate your team's expertise and resources. Not all solutions fit every situation, and a mismatch can be frustrating. Assessing these factors helps ensure you choose a sensor that aligns with your project's goals and constraints.

Related Posts

-

Why Understanding Compression Force Sensors Is Crucial for Modern Industries

-

Understanding the Impact of 3 Axis Force Sensors on Modern Robotics and Automation

-

Unlocking Precision: The Future of 3-Axis Force Sensors in 2025's Top Innovations

-

5 Key Advantages of Choosing the Best Force Transducer for Your Applications

-

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements

-

Unlocking Efficiency: Key Advantages of Utilizing Compression Load Cells in Industrial Applications