sales@loadcellsensor.com

sales@loadcellsensor.com

Ultimate Guide to Choosing the Best S Beam Load Cell for Your Applications

In today's rapidly evolving industrial landscape, the demand for precision and reliability in weighing solutions is more critical than ever.

S Beam Load Cells are pivotal components used in a variety of applications, from material testing to industrial automation.

According to a recent market research report by Technavio, the global load cell market is expected to grow by USD 109.73 million, progressing at a CAGR of over 5% through 2025, indicating a robust demand for accurate weighing technologies.

This growing trend emphasizes the importance of choosing the right S Beam Load Cell tailored to specific requirements.

Selecting the best S Beam Load Cell not only enhances operational efficiency but also ensures accurate measurement, thus playing a crucial role in optimizing processes across various sectors.

In this ultimate guide, we will explore the key considerations and factors to help you make an informed decision when selecting an S Beam Load Cell for your applications.

S Beam Load Cells are pivotal components used in a variety of applications, from material testing to industrial automation.

According to a recent market research report by Technavio, the global load cell market is expected to grow by USD 109.73 million, progressing at a CAGR of over 5% through 2025, indicating a robust demand for accurate weighing technologies.

This growing trend emphasizes the importance of choosing the right S Beam Load Cell tailored to specific requirements.

Selecting the best S Beam Load Cell not only enhances operational efficiency but also ensures accurate measurement, thus playing a crucial role in optimizing processes across various sectors.

In this ultimate guide, we will explore the key considerations and factors to help you make an informed decision when selecting an S Beam Load Cell for your applications.

Understanding S Beam Load Cells: What Sets Them Apart?

S beam load cells are a unique type of load measuring device known for their simplicity and versatility. What sets them apart from other types of load cells is their distinct shape and the way they utilize bending moments to measure weight. Typically constructed from high-quality materials like stainless steel, S beam load cells are capable of providing high accuracy and are ideal for tension and compression applications. According to a recent market report by TechSci Research, the global load cell market is expected to witness significant growth, driven by the increasing demand for high-precision measuring instruments across various industries.

When selecting an S beam load cell, consider factors such as capacity, accuracy, and environmental conditions. It’s essential to match the load cell's specifications with your application requirements. For instance, if you plan to use the load cell in a moisture-prone environment, opt for a model with an IP rating to ensure durability.

Additionally, keep in mind that proper installation and calibration are critical for optimal performance. Ensure that the load cell is mounted correctly, and allow it to be calibrated by a professional to maintain measurement precision over time. Remember, investing time in these details will enhance the longevity and reliability of your load cell system.

Comparative Analysis of S Beam Load Cells by Capacity

This chart displays the accuracy of various S Beam Load Cells based on their weight capacities. As the capacity increases, the accuracy margin also tends to increase, which is important to consider when selecting an appropriate load cell for specific applications.

Key Factors to Consider When Choosing an S Beam Load Cell

When selecting an S Beam load cell for your applications, several key factors should be taken into consideration to ensure optimal performance and accuracy. First and foremost, understand the load capacity you require. S Beam load cells come in various capacities, typically ranging from a few grams to several tons. It’s essential to choose a load cell that can handle the maximum load you intend to measure while providing a safety margin to prevent overload and potential damage.

Another critical factor is the environmental conditions where the load cell will be used. Considerations such as temperature range, humidity, and exposure to corrosive substances can significantly impact the performance of the load cell. For instance, if your application involves extreme temperatures or corrosive environments, selecting a load cell with suitable materials and sealing options is crucial. Additionally, factors like the desired accuracy and precision, as indicated by the load cell’s specifications, should guide your final choice, ensuring that the load cell meets the precision requirements of your specific application.

Ultimate Guide to Choosing the Best S Beam Load Cell for Your Applications

| Parameter | Description | Importance |

|---|---|---|

| Measurement Range | The load cell's capacity to measure different weights, usually expressed in pounds or kilograms. | High |

| Accuracy | The precision of the load cell in measuring the actual weight, often represented as a percentage of full scale. | High |

| Material | The type of material used in the construction of the load cell, affecting durability and environmental resistance. | Medium |

| Temperature Range | Operational temperature limits within which the load cell can function accurately. | High |

| Output Signal | The type of electrical signal produced by the load cell, such as analog or digital. | Medium |

| Mounting Options | Various methods available for installing the load cell in different applications. | Medium |

| Certification | Industry certifications that indicate compliance with standards for quality and safety. | High |

Exploring Different Applications for S Beam Load Cells

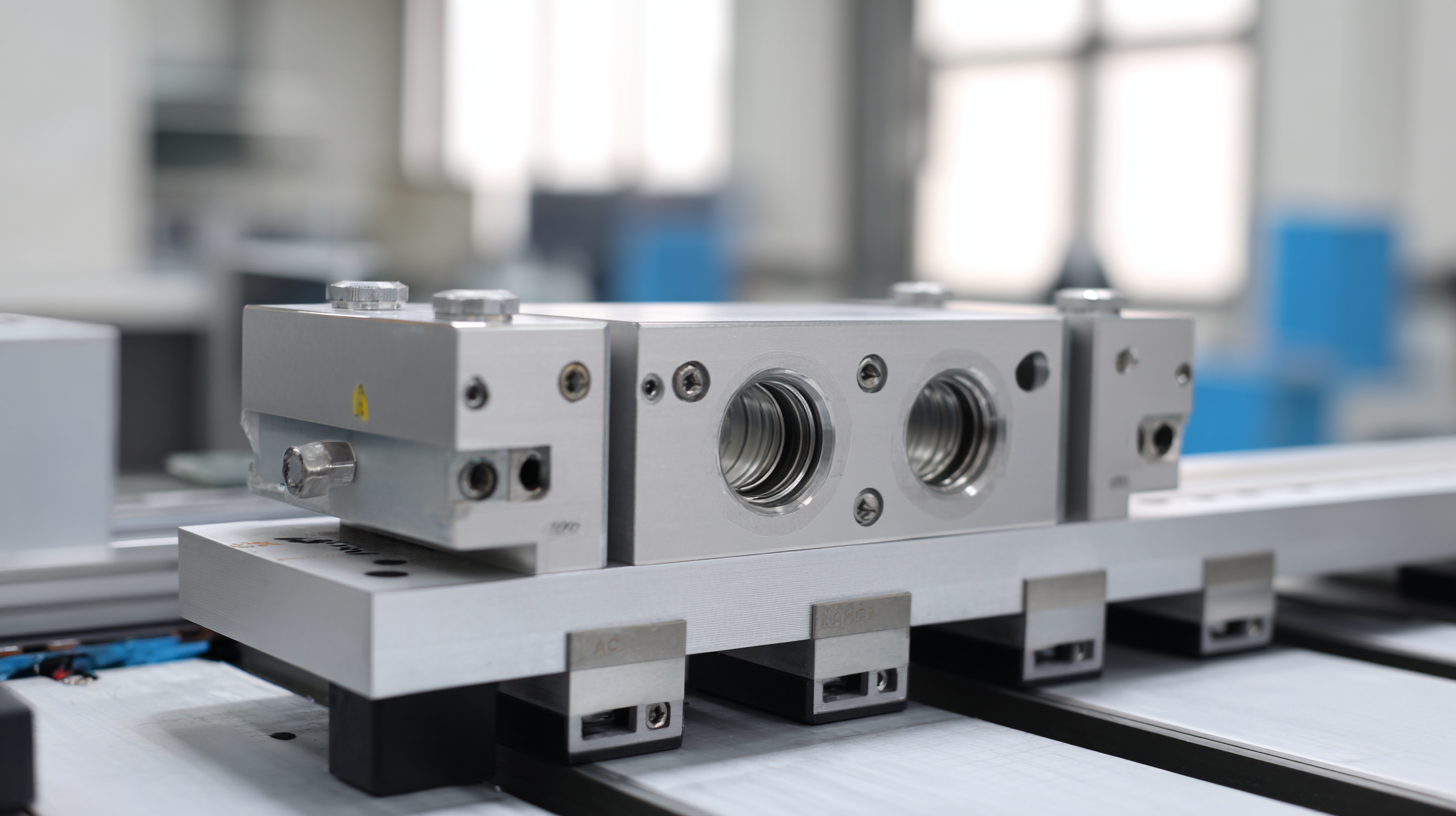

S Beam load cells are versatile sensors widely used across various applications due to their ability to measure tension and compression forces accurately. One of the most common uses is in weighing systems, where they can be integrated into scales for industrial and retail environments. The slim design of S Beam load cells makes them ideal for integration into confined spaces, which is particularly beneficial in automated weighing systems or when retrofitting existing equipment.

In addition to weighing, S Beam load cells are prominently featured in the aerospace and automotive industries, where they assist in monitoring structural integrity and load distributions. For instance, they can be employed in fatigue testing of components or in applications where precise force measurements are crucial for safety and performance assessments. Their capability to function under varying environmental conditions also makes them suitable for harsh industrial setups, ensuring reliable performance across diverse scenarios. By understanding these applications, you can better appreciate the importance of selecting the right S Beam load cell for your specific needs.

Future Innovations in S Beam Load Cell Technology

The future of S Beam load cell technology is poised for remarkable innovations that will enhance accuracy and performance across various applications. Recent industry reports suggest that the global load cell market is expected to grow from $1.8 billion in 2021 to approximately $2.7 billion by 2026, driven largely by advancements in sensor technology and the increasing demand for automation in manufacturing processes. These improvements promise to provide load cells with increased precision, reduced error margins, and enhanced durability, making them more reliable for industries such as aerospace, automotive, and construction.

Tip: When selecting an S Beam load cell, consider looking for models equipped with integrated wireless connectivity. This feature facilitates real-time data transmission, allowing for immediate analysis and improved efficiency in monitoring weight loads, particularly in dynamic environments.

Moreover, the incorporation of smart technology is set to revolutionize how load cells are utilized. Innovations like IoT-enabled S Beam load cells are now entering the market, enabling seamless integration into smart manufacturing systems. According to a recent study by MarketsandMarkets, the adoption of IoT solutions in load cell technologies is anticipated to grow by over 22% annually, reflecting a significant shift towards smarter, more interconnected equipment that can adapt to evolving industrial demands.

Tip: Opt for S Beam load cells that offer customizable software solutions, which can be tailored to meet specific application requirements, ensuring optimal performance and user flexibility in data handling.

Comparative Analysis: S Beam Load Cells vs. Other Load Cell Types

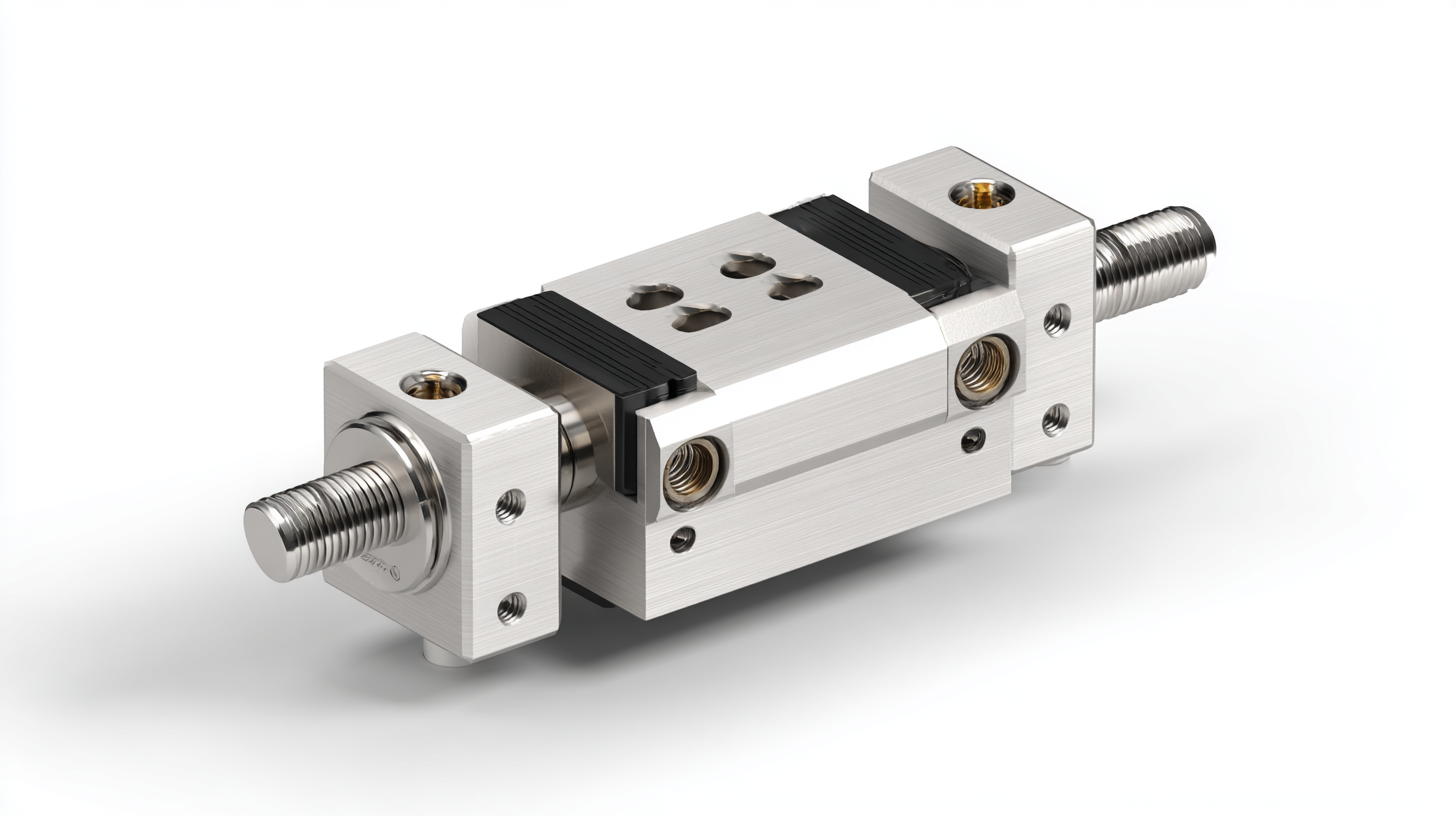

When selecting a load cell for your application, it is crucial to consider the unique advantages that S Beam load cells offer compared to other types. S Beam load cells excel in tension and compression applications and are known for their compact design, which allows for easy installation in tight spaces. In contrast, other types such as bending beam load cells may not perform as reliably under both tension and compression, making S Beam a versatile choice.

Tips: Ensure that the load cell's capacity matches your application's requirements, as oversized or undersized load cells can lead to measurement inaccuracies. Additionally, consider the environmental factors—such as temperature and humidity—that may affect the load cell’s performance, especially when comparing S Beam load cells to other types like shear beam or pancake cells.

Another advantage of S Beam load cells is their inherent structural design, which provides excellent stability and reduces the likelihood of unwanted deflection. This characteristic makes them less susceptible to errors from external forces. In contrast, other load cell types may require additional support to maintain accuracy under varying loads.

Tips: When assessing load cells for your project, pay attention to the calibration process and ensure that the chosen load cell offers a suitable method for your specific application. Regular maintenance and recalibration will ensure optimal performance over time, regardless of the type of load cell you choose.