sales@loadcellsensor.com

sales@loadcellsensor.com

How to Choose the Right 5kg Load Cell for Your Needs?

When selecting a 5kg load cell, precision is vital. Dr. Emily Carter, a leading expert in sensor technology, emphasizes, "Choosing the right load cell can significantly impact measurement accuracy." A 5kg load cell is essential in various applications, from industrial scales to medical devices. Knowing its features can guide your decision.

It's easy to overlook specifics. The construction and materials of the 5kg load cell can affect performance. For instance, stainless steel models often offer better durability. Common challenges include varying load conditions and temperature effects. Evaluating these factors is crucial.

Experts recommend looking at the load cell's specifications closely. Strain gauges, for example, play a significant role in reliability. A 5kg load cell must be tested for the intended environment. Each application requires careful consideration to ensure optimal performance and avoid potential issues. Striking the right balance will lead to successful results.

Understanding Load Cells: Basics and Types

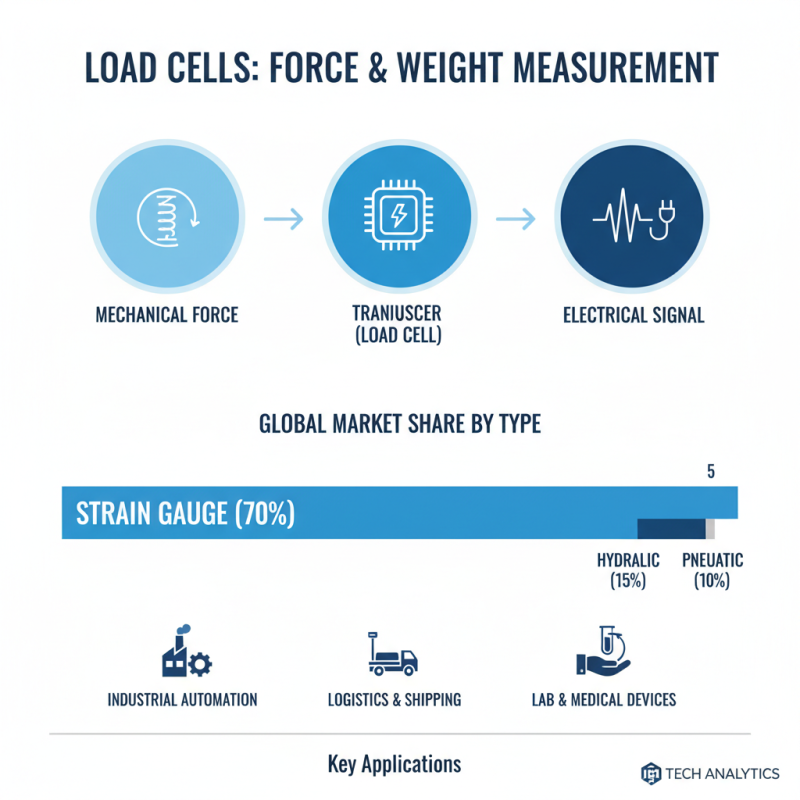

Load cells are crucial devices used for measuring weight or force. They convert mechanical force into an electrical signal. Key types include strain gauge, hydraulic, and pneumatic load cells. Each type serves different purposes and offers unique advantages. Strain gauge load cells dominate the market, accounting for over 70% of all load cell usage, according to industry reports.

Understanding specifications is critical. For example, a 5kg load cell must exhibit high precision and stability. Reports suggest that precision levels can vary significantly between types. Strain gauge cells typically offer 0.03% full scale accuracy. This makes them ideal for applications requiring meticulous measurements. Conversely, hydraulic load cells may withstand extreme conditions, yet they often lack the fine resolution of their electronic counterparts.

Choosing the right load cell is not merely a technical decision. It also involves considering the environment where it will operate. Temperature fluctuations and humidity can impact performance. A study showed that 15% of load cell failures were due to environmental factors. Thus, careful evaluation of both specifications and conditions is essential for optimal performance.

Factors to Consider When Choosing a 5kg Load Cell

Choosing the right 5kg load cell starts with understanding your specific needs.

Consider where you will use it. Is it for a small lab project or a home scale? Each application may require different features.

Think about the required accuracy. A more precise load cell can increase costs,

but it’s vital for certain tasks.

Another important factor is the load cell’s environmental tolerance.

Will it face extreme temperatures or humidity? Some load cells are designed for harsh conditions.

Make sure to pick one that can withstand your environment. Also, pay attention to the material.

Stainless steel is common, but there are other options. Each material has its pros and cons.

It's easy to overlook the installation process.

Some load cells may require complex setups. Evaluate your skills and the tools at your disposal.

Be ready to modify plans if needed. If the load cell is too complicated, it may affect its performance.

This could lead to unnecessary errors. Reflecting on these details can guide you to a suitable choice.

Calibration and Accuracy in Load Cell Selection

Calibration is a pivotal factor when selecting a 5kg load cell. Proper calibration ensures that measurements are accurate and consistent, which is vital in various applications. According to industry standards, an accuracy of ±0.1% is often considered acceptable for high-precision tasks. However, users frequently overlook this aspect. They may assume that any load cell will suffice, leading to potential errors.

The calibration process may require specific adaptation for unique environments. For instance, temperature fluctuations can affect readings. A recent study indicates that a 5°C change can shift load cell readings by up to 0.05%. Ensuring proper calibration can mitigate these discrepancies, yet many users find this step tedious. It’s crucial to recognize that neglecting this procedure can lead to significant inefficiencies.

Another common mistake is underestimating the importance of regular calibration. A report suggests that load cells should be recalibrated every 6 to 12 months, depending on usage. Skipping this step can result in cumulative errors. Users often feel confident after initial calibration, ignoring the wear and tear that occurs. Awareness and diligence in maintaining calibration standards can enhance overall performance and reliability in load cell applications.

Applications and Industry Uses for 5kg Load Cells

5kg load cells are versatile components used in various industries. They measure weight and force, making them essential in manufacturing and logistics. In food production, load cells ensure the correct weight for packaging. This is crucial for maintaining standards and reducing waste. They help businesses remain compliant with regulations.

In the medical field, 5kg load cells support weighing scales. Precision is vital here. Inaccurate readings can lead to serious consequences. With that in mind, many companies need to assess their choices carefully. Load cells should be reliable and accurate. Sometimes, users may overlook essential specifications. This can result in performance issues.

Another interesting application is in robotics. 5kg load cells assist in load measurements. Robots can adjust their operations based on this data. However, not all load cells are easy to integrate. Compatibility can be a concern for many projects. It is essential to evaluate this aspect before making a choice. Proper selection impacts performance.

Installation and Maintenance Tips for Load Cells

Installation and maintenance of load cells are crucial for their performance and longevity. Proper installation helps in achieving accurate measurements. Tightening screw connections to the manufacturer's specifications is essential. The alignment of the load cell with the applied force must be precise. An industry report suggests that improper alignment can lead to performance errors of up to 15%.

Regular maintenance is also vital. Load cells should be inspected for signs of wear. Check for corrosion or damage, especially in harsh environments. A staggering 30% of load cell failures are due to neglect in maintenance. Keeping the load cell clean is important. Dust and debris can interfere with its sensitivity. Using a soft cloth is often enough to maintain its condition.

Load cells should be calibrated periodically. Calibration ensures accuracy over time. An industry guideline suggests calibrating every 6-12 months, depending on usage. If you notice discrepancies, recalibration is necessary. This can also extend the load cell's lifespan. Not taking these steps can lead to unreliable data and potential costly errors. Reflecting on these practices can improve both safety and efficiency in operations.

5kg Load Cell Performance Characteristics

This chart illustrates the key performance characteristics of a 5kg load cell, including precision, linearity, hysteresis, temperature coefficient, and sensitivity. Understanding these specifications can help you choose the right load cell for your needs.

Related Posts

-

How to Choose the Perfect Thin Load Cell for Your Industrial Applications

-

Discovering the Best Compression Load Cells: A Global Buyer’s Guide for Performance and Reliability

-

5 Essential Tips for Choosing the Right Tension Compression Load Cell

-

5 Proven Weight Sensor Technologies Revolutionizing the Industry

-

15 Best Practices for Using Tension Compression Load Cell in Industry

-

Unlocking Efficiency: Key Advantages of Utilizing Compression Load Cells in Industrial Applications