sales@loadcellsensor.com

sales@loadcellsensor.com

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements

In the field of precision measurement and industrial applications, the significance of selecting the right Hollow Load Cell cannot be overstated. With the global market for load cells expected to reach nearly $3 billion by 2025, according to industry reports, the demand for accuracy and reliability in force measurement is more critical than ever. Hollow Load Cells, known for their unique design that accommodates varying load applications, offer the versatility required in numerous sectors, from manufacturing to aerospace.

As industries continue to innovate and evolve, understanding the selecting criteria for Hollow Load Cells is vital for engineers and technical professionals alike. Reports indicate that improper selection can lead to measurement inaccuracies that may account for up to 20% of operational inefficiencies in manufacturing processes. By gaining insight into the characteristics that define a suitable Hollow Load Cell—such as capacity, sensitivity, and temperature stability—users can ensure their investment leads to enhanced performance and cost-effectiveness.

Ultimately, the choice of a Hollow Load Cell can significantly impact the quality of measurements and the overall success of projects. Therefore, navigating through the options available in the market becomes imperative to leverage the full potential of advanced load cell technology.

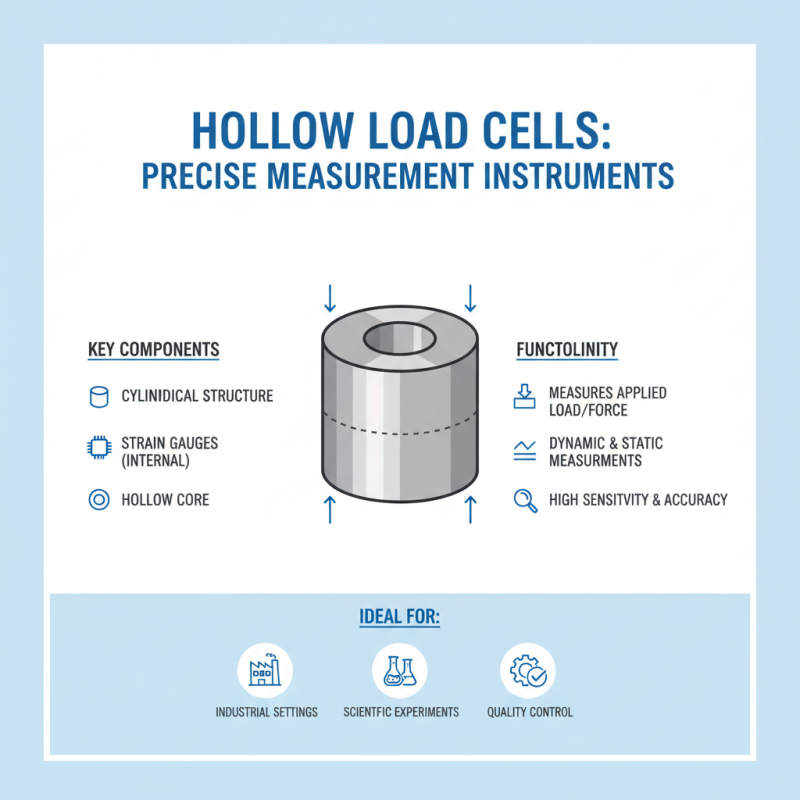

Understanding the Basics of Hollow Load Cells in Measurement Applications

Hollow load cells are essential instruments in various measurement applications, providing precise weight and force data. Understanding the basic components and functionality of hollow load cells is crucial for selecting the right model for specific needs. These devices typically consist of a cylindrical structure that can measure loads applied to it, making them ideal for dynamic and static measurements in industrial settings. Their unique design allows for high sensitivity and accuracy, which is imperative when precise measurements are required, such as in scientific experiments or quality control processes.

Recent advancements, such as the development of hollow spheres for drug release applications, highlight the versatility of hollow structures in technology. These hollow spheres, synthesized with magnetite and guided by micelles, demonstrate how hollow forms can be used to achieve responsive systems. When applied to medical technology, such innovative designs can improve drug delivery by allowing controlled and stimulus-responsive release. Similarly, in weight measurement, the adoption of hollow load cells can significantly enhance accuracy and responsiveness, making them invaluable in both scientific research and industrial applications.

Key Specifications to Consider When Selecting a Hollow Load Cell

When selecting a hollow load cell for accurate measurements, there are several key specifications to consider. Load cells are critical in various industries, from manufacturing to research, and understanding these specifications can significantly impact the precision of weight measurements. One of the primary factors is the capacity of the load cell, which should align with the maximum load expected during use. According to industry reports, a load cell with a 0.1% accuracy rating can improve measurement reliability and consistency in dynamic applications.

Another important aspect to evaluate is the material and construction of the hollow load cell. Cells made from stainless steel exhibit not only durability but also resistance to corrosion, making them suitable for harsh environments. Additionally, the temperature range specified for the load cell is crucial, as performance can fluctuate with extreme temperatures. Various studies indicate that choosing a load cell with proper temperature compensation can reduce measurement errors significantly, sometimes by as much as 50% in volatile conditions.

Tip: Always ensure that the specifications of the load cell align with the application requirements to avoid errors.

Tip: Consider the signal output type and compatibility with existing systems to simplify integration and maintain measurement integrity.

Comparing Accuracy and Sensitivity Across Different Load Cell Models

When selecting a hollow load cell, it's essential to consider both accuracy and sensitivity, as these factors directly affect measurement outcomes. Accuracy refers to how closely the load cell readings match the actual load applied, while sensitivity indicates the load cell's ability to detect small changes in force. Different models may excel in one area but lag in another, making it vital to understand their specifications thoroughly.

For example, some advanced hollow load cells are designed with enhanced materials and technology that improve their accuracy. They may utilize high-resolution sensors that offer finer measurements, making them ideal for applications where precision is critical. On the other hand, certain models might prioritize sensitivity, allowing them to detect minute changes in weight, which can be particularly useful in research and development settings. By comparing these attributes across various load cell models, users can identify the right instrument that aligns with their specific measurement needs.

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements - Comparing Accuracy and Sensitivity Across Different Load Cell Models

| Model | Capacity (kg) | Accuracy (%) | Sensitivity (mV/V) | Temperature Range (°C) |

|---|---|---|---|---|

| Model A | 500 | ±0.02 | 2.0 | -10 to 60 |

| Model B | 1000 | ±0.01 | 2.5 | -20 to 70 |

| Model C | 250 | ±0.03 | 1.8 | -10 to 50 |

| Model D | 2000 | ±0.015 | 3.0 | -10 to 80 |

Evaluating Environmental Conditions for Optimal Load Cell Performance

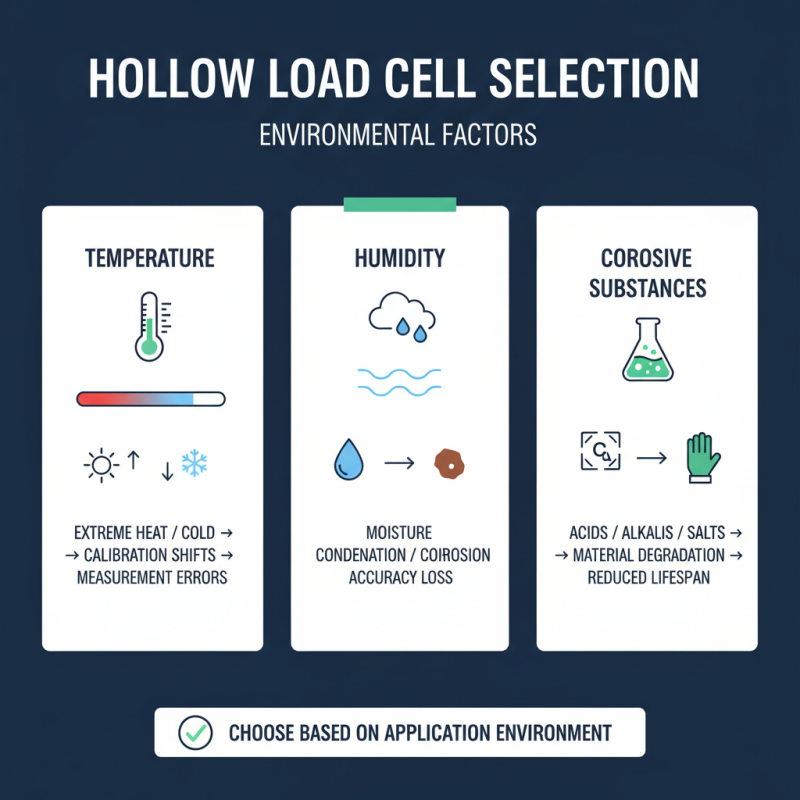

When selecting a hollow load cell, understanding the environmental conditions in which it will operate is crucial for ensuring optimal performance. Factors such as temperature, humidity, and exposure to corrosive substances can significantly influence the accuracy and longevity of the load cell. For instance, extreme temperatures can alter the load cell's calibration, leading to error in measurements. Therefore, it is essential to choose a load cell designed to withstand the specific environmental conditions of your application.

Additionally, the presence of vibrations and mechanical shocks can impact the performance of load cells. Environments with high levels of vibration may require load cells equipped with dampening features or those that are specifically engineered for such conditions. Considering the installation location is also important; for example, load cells used outdoors may need to be rated for weather resistance to prevent damage. By carefully evaluating these environmental conditions, you can ensure that the chosen hollow load cell will provide reliable and accurate measurements throughout its operational life.

Industry Standards and Certifications for Reliable Load Cell Measurements

When selecting a hollow load cell for accurate measurements, understanding industry standards and certifications is crucial. The International Organization for Standardization (ISO) plays a significant role in establishing these benchmarks, particularly ISO 376, which focuses on the calibration of force-proving instruments. This standard ensures that load cells meet precision requirements and verify their accuracy against known forces. Furthermore, the OIML R60 certification addresses the reliability of load cells, particularly in legal metrology, affirming that these instruments can provide accurate measurements essential in various industries, including manufacturing and construction.

Recent market analyses indicate that over 70% of manufacturers prioritize certified load cells in their operations, underscoring the importance of these standards. For instance, recent data from the National Institute of Standards and Technology (NIST) highlights that certified load cells exhibit a measurement error margin of less than 0.5%, compared to non-certified alternatives which can reach error rates of 2% or higher. This significant disparity can impact production efficiency and compliance with safety regulations, making adherence to industry standards not just beneficial, but necessary for achieving optimal operational performance.

2025 Hollow Load Cell Performance Comparison

This chart illustrates the performance of various hollow load cells based on their accuracy and load capacity, highlighting industry standards and certifications necessary for reliable measurements.

Related Posts

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs

-

Top 5 Micro Load Cells for Accurate Measurement in Industrial Applications

-

Ultimate Checklist for Choosing the Best Compression Type Load Cell for Your Business Needs

-

Unlocking Industry Potential with Strain Gauge Load Cells at the 2025 China Import and Export Fair

-

Common Issues Faced When Using Best Small Load Cells

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide