sales@loadcellsensor.com

sales@loadcellsensor.com

How to Choose the Right Pull Force Sensor for Your Applications

In the evolving landscape of industrial automation, selecting the correct Pull Force Sensor is critical. A recent report from TechSci Research highlights that the global pull force sensor market is expected to reach $2 billion by 2025, driven by increased demand for precision in various applications. These sensors are essential in industries like manufacturing and robotics.

John Smith, a leading expert in sensor technology, stated, "Choosing the right pull force sensor can significantly enhance operational efficiency." It's important to consider factors such as accuracy, response time, and load capacity when making a choice. However, many users overlook these aspects. They often choose sensors based on cost rather than suitability, which can lead to underperformance.

The pull force sensor industry faces challenges. Some products may not meet performance expectations, leading to frustration. Users must also navigate issues like calibration and integration with existing systems. Understanding the nuances of pull force sensors helps mitigate these issues and improves overall application success.

Understanding Pull Force Sensors and Their Applications

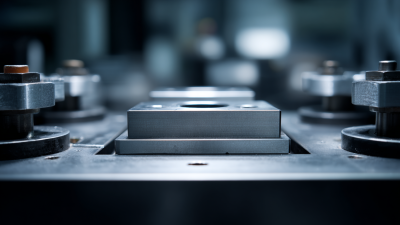

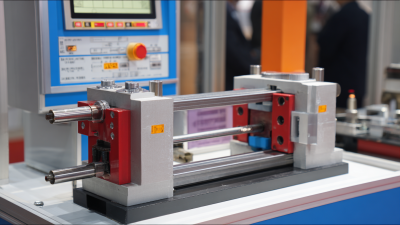

Pull force sensors play a vital role in various applications. They measure the force applied to an object during pulling. This data is essential in fields like manufacturing, robotics, and testing. Understanding how these sensors operate can improve your project outcomes.

Different pull force sensors vary in design and sensitivity. Some sensors are more adaptable for dynamic environments. Others are suited for static measurements. When selecting a sensor, consider factors like the range of force and accuracy needed. Yet, it’s easy to overlook details. Choosing the wrong sensor could lead to inaccurate data. This might disrupt operations or lead to incorrect conclusions.

Installation can be tricky, and calibration is often overlooked. A poorly calibrated sensor can give misleading readings. Testing under varied conditions is crucial. It helps ensure the sensor responds correctly to real-world scenarios. Make sure to reflect on these aspects before making a choice. Proper evaluation minimizes risks and enhances efficiency.

How to Choose the Right Pull Force Sensor for Your Applications

| Sensor Type | Measurement Range | Accuracy | Response Time | Applications |

|---|---|---|---|---|

| Load Cell | 0-2,000 lbs | ±0.5% | 1 ms | Automotive testing, Material testing |

| Tension Sensor | 0-500 N | ±1% | 2 ms | Robotics, Manufacturing |

| Force Gauge | 0-1,000 lbs | ±0.2% | 5 ms | Quality assurance, Laboratory testing |

| Strain Gauge | 0-10,000 N | ±0.1% | 10 ms | Civil engineering, Research |

| Digital Force Sensor | 0-500 lbs | ±0.5% | 1 ms | Electronics, Aerospace testing |

Key Specifications to Consider When Selecting a Pull Force Sensor

When choosing a pull force sensor, specifications play a critical role. A sensor's accuracy is vital. This depends on its resolution and measurement range. Higher resolution means better detection of small force changes. You need to assess the maximum and minimum force the sensor can handle. If your application involves delicate measurements, a sensor with precise calibration is imperative.

The sensor's operating temperature range is another key aspect. Extreme environments can affect performance. Many sensors can only perform well within certain temperature limits. Durability is also significant. Some sensors are designed for harsh conditions. Others may fail quickly if exposed to moisture or dust. The choice depends on where you intend to use them.

It’s essential to have a clear understanding of your application’s requirements. Sometimes, people overlook connection types. A sensor may come with various output options. Ensure compatibility with your existing system. Always consider the mounting method. Misalignment can lead to erroneous readings. Take the time to evaluate these factors carefully. Making hasty decisions may wind up costing more in revisions later.

Pull Force Sensor Selection Criteria

Evaluating Precision and Accuracy in Pull Force Measurement

Choosing the right pull force sensor is crucial for various applications. Precision and accuracy are vital when measuring pull forces. Many sensors offer different specifications. However, not all may meet your specific needs. Understanding these terms helps in making the right choice.

Precision refers to the reproducibility of the measurements. It shows how closely the repeated measurements cluster together. On the other hand, accuracy indicates how close a measurement is to the true value. A sensor could be precise yet not accurate. Therefore, balance is necessary.

Users often overlook calibration. Regular checks ensure continuous performance. Environmental factors can also affect results. Temperature, humidity, and vibrations may skew measurements. Knowing these potential pitfalls can aid in better selections. Moreover, a sensor’s user interface varies. Intuitive designs help operators understand data quickly, yet some interfaces can be confusing. Reflecting on these details is key to better application outcomes.

Industry Standards and Compliance for Pull Force Sensors

When selecting a pull force sensor, understanding industry standards is crucial. Compliance ensures the sensor will function correctly in your application. Different sectors, like manufacturing and healthcare, have specific requirements. Ignoring these can lead to serious issues. Selecting a non-compliant sensor may result in inaccurate measurements and operational failures.

Certifications such as ISO or ASTM play an essential role in this process. These standards provide guidelines that help evaluate sensor performance. A lack of familiarity with these can lead to erroneous choices. Sensor materials must also comply with safety standards to avoid contamination in sensitive environments. For instance, a sensor used in food processing must withstand strict hygiene regulations.

Finally, consider testing and validation reports. These documents prove that the sensor meets the required standards. However, not all sensors undergo rigorous testing. This inconsistency can mislead users. Always scrutinize these reports to ensure reliability. Each application is unique, and a one-size-fits-all approach may not be practical. Choose wisely, as this decision impacts your operational efficiency and safety.

Comparative Analysis of Different Pull Force Sensor Types

When selecting a pull force sensor, different types offer various advantages. Strain gauge sensors are highly precise and commonly used. They measure deformation of materials. These sensors provide reliable readings for small pulls. However, they can be sensitive to temperature changes.

Another option is capacitive sensors. They work by measuring changes in capacitance. These sensors are less affected by environmental conditions. They can handle a wider range of forces. Yet, their accuracy may decline at very low or very high forces. They may require more calibration.

Tips: Evaluate the environmental factors. Consider temperature and humidity. These can influence sensor performance. Test sensors in real-world applications before making decisions. Always document your findings to learn and adjust. A systematic review of results will help in future selections.

Related Posts

-

10 Compelling Reasons to Choose Force Sensors for Your Next Project

-

Navigating the Best Force Sensor Market How to Identify Top Manufacturers with Key Comparisons

-

Why Understanding Compression Force Sensors Is Crucial for Modern Industries

-

Unlocking Industry Potential with Strain Gauge Load Cells at the 2025 China Import and Export Fair

-

How to Choose the Right Torque Sensor for Your Application Needs

-

How Rigging Load Cells are Revolutionizing Modern Weight Measurement in Construction