sales@loadcellsensor.com

sales@loadcellsensor.com

How to Choose the Right Wire Rope Load Cell for Your Needs?

Choosing the right Wire Rope Load Cell is crucial for various industries. These devices measure weight and force with precision. According to a report by Global Market Insights, the wire rope load cell market is expected to reach $1.2 billion by 2025. This growth reflects a rising demand for accurate load measurement in sectors like construction and manufacturing.

Experts emphasize the need for careful selection. John Smith, a leading figure in load measurement technology, states, "Choosing the right load cell can significantly impact efficiency and safety." This highlights the importance of understanding specific requirements before making a decision.

Test load capacities, environmental conditions, and installation methods are key considerations. A mismatch could lead to inaccuracies or even equipment failure. It's essential to reflect on these aspects and ensure the chosen Wire Rope Load Cell aligns with operational demands.

Importance of Wire Rope Load Cells in Industrial Applications

Wire rope load cells play a critical role in various industrial applications. These devices measure tension and can enhance worker safety. They are essential in sectors like construction, shipping, and manufacturing. According to a recent industry report, around 70% of lifting equipment now integrates this technology. This shift shows their growing importance.

In construction, accurate load measurements prevent accidents. A report highlights that improper loads account for 45% of lifting injuries. This underscores the need for reliable wire rope load cells. Choosing the correct model is vital for safety and efficiency. Factors like load capacity and environmental conditions should guide your selection.

Tips: Always check the load cell's specifications. Consider how it will perform in different environments. Regular maintenance is crucial too. Ignoring this can lead to failures. Take into account that not all cells are built alike; some may not withstand harsh conditions. Make informed choices based on detailed specifications and real-world scenarios.

Key Specifications to Consider When Selecting Wire Rope Load Cells

When selecting wire rope load cells, several key specifications are critical to ensure optimal performance. The capacity of the load cell is paramount. Common ranges vary from 1 ton to over 300 tons. Choosing a cell with insufficient capacity can lead to failure. It's essential to assess the maximum loads and select accordingly.

Another important factor is the environmental conditions. Load cells are often exposed to harsh conditions. Selecting a corrosion-resistant model is vital. According to industry reports, around 30% of load cell failures are due to environmental damage. Additionally, the accuracy and resolution must not be overlooked. Many models offer a precision of 0.1% to 1%. Higher accuracy provides better data but can increase costs. However, if the application demands precise measurements, it’s worth considering.

Lastly, installation ease is also crucial. Some models are complex to install, which may lead to errors. Industry experts suggest investing time in understanding the installation process to prevent complications. Remember, the right choice can enhance safety and efficiency in operations. Always weigh the pros and cons carefully.

Load Cell Types: Understanding Different Designs and Their Benefits

When selecting a wire rope load cell, understanding the different designs is crucial. Several types exist, each with unique benefits. For instance, tension load cells are great for measuring the force exerted on a cable. They are commonly used in lifting applications. Compression load cells, on the other hand, excel in weighing heavy objects on stable surfaces. Their design minimizes errors caused by lateral forces.

Another type to consider is the shear beam load cell. This design is popular in industrial settings. It provides accurate measurements while being adaptable to various environments. Furthermore, load buttons are compact and ideal for small spaces. Each choice serves specific needs, highlighting the importance of context. However, picking the right one can feel overwhelming. Potential users may find the sheer variety intimidating.

Each load cell type has its strengths but also limitations. A tension cell might struggle in a highly dynamic environment. Meanwhile, a shear beam may not provide enough resolution for fine measurements. It's essential to consider the application carefully. Reflecting on the requirements will guide the selection process. Understanding your needs is vital.

How to Choose the Right Wire Rope Load Cell for Your Needs?

| Load Cell Type | Design | Application | Load Capacity | Benefits |

|---|---|---|---|---|

| Single Point | Rectangular design with a single loading point | Crane scales, platform scales | Up to 1000 kg | High accuracy, compact size |

| Bending Beam | Beam structure with bending load sensing | Industrial weighing, tank weighing | Up to 3000 kg | Cost-effective, wide measurement range |

| S-Type | S-shaped design for tension and compression | Hanging scales, material testing | Up to 5000 kg | Versatile, reliable load measurement |

| Canister | Cylindrical design for robust usage | Heavy-duty weighing, load testing | Up to 10000 kg | High durability, excellent structural integrity |

| Tension Load Cell | Long cylindrical shape for tension measurements | Hoisting, rope tension monitoring | Up to 2000 kg | Accurate, ideal for dynamic applications |

Performance Factors: Capacity, Accuracy, and Sensitivity of Load Cells

When selecting a wire rope load cell, consider its performance factors like capacity, accuracy, and sensitivity. The capacity is crucial; it determines the load the cell can handle. If you underestimate this, it could lead to failure. Too much weight can damage the load cell and your equipment.

Accuracy is another key component. Load cells often come with specified accuracy levels. However, real-world factors like temperature or environmental conditions can affect this. Always check the specifications and choose a model that meets your requirements.

Tip: Regularly calibrate your load cell. Calibration ensures that your readings remain accurate over time.

Sensitivity refers to how well the load cell detects small changes in load. Higher sensitivity means better detection of minor weight changes. This can be particularly valuable in precise applications. However, a more sensitive load cell may also require more maintenance.

Tip: Assess the environment the load cell will operate in. Factors such as humidity, dust, or vibrations can impact performance. Consider investing in protection measures.

Load Cell Performance Factors

This chart illustrates the key performance factors of wire rope load cells including capacity, accuracy, and sensitivity. Understanding these metrics helps in selecting the right load cell for your specific needs.

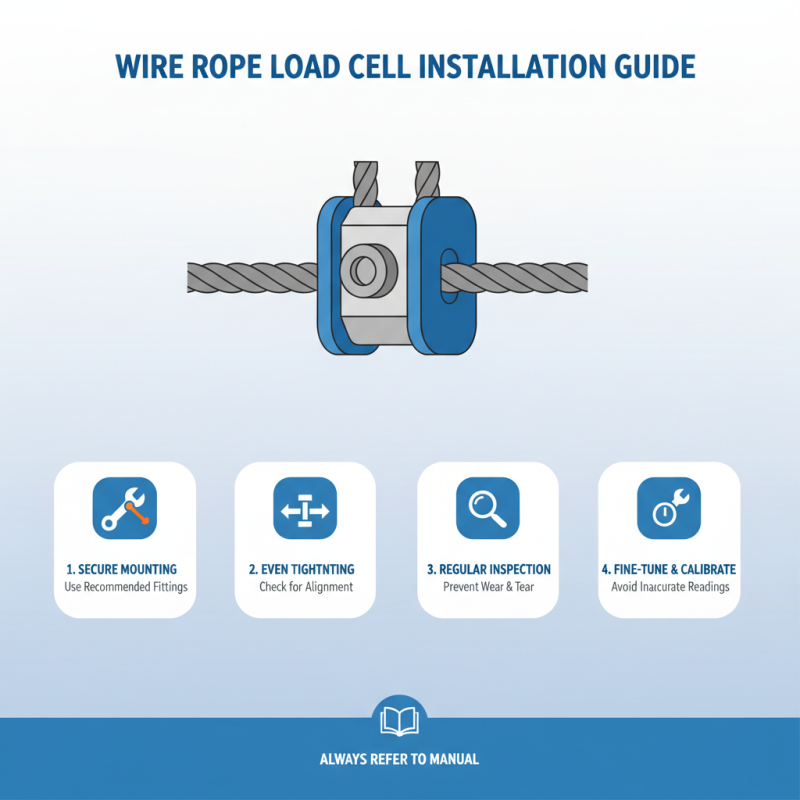

Installation and Maintenance: Best Practices for Longevity and Accuracy

When it comes to installation, precision is key. Ensure the wire rope load cell is mounted securely. Use the recommended fittings to avoid slippage during operation. Tighten bolts evenly, checking for any misalignment. Regularly inspect connections for wear and tear. A loose connection can lead to inaccurate readings. Small adjustments can make a significant difference. Always refer to the installation manual for specific details.

Maintenance is equally important. Periodically calibrate the load cell to ensure its accuracy. Dust and debris can affect performance. Clean the load cell with a soft cloth, avoiding harsh chemicals. Examine the wire rope for fraying or damage. If you notice any issues, it might be time to replace it. Regular checks can prevent larger failures down the line. Keep a maintenance log to track performance and issues. This helps identify patterns over time. After all, proactive care leads to better longevity and efficiency.

Related Posts

-

The Ultimate Guide to Sourcing High-Quality Suppliers for Best Button Type Load Cells

-

Understanding Inline Load Cells: Revolutionizing Weight Measurement in Modern Industries

-

Top Pancake Load Cell Applications in Industry and Science?

-

How to Choose Load Cell Sensors for Accurate Measurements?

-

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements

-

What Is a Wire Rope Load Cell and How Does It Work in Weighing Applications?