sales@loadcellsensor.com

sales@loadcellsensor.com

How to Choose the Best Torque Meter for Your Motor Needs?

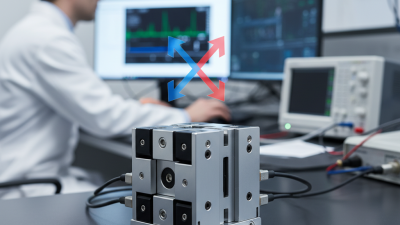

When selecting a torque meter for motor applications, precision is key. Understanding your specific needs can greatly impact performance. John Smith, an expert in torque measurement technology, states, "Choosing the right torque meter can optimize motor efficiency."

In the world of motors, torque meters play a crucial role. They ensure that the torque specifications are met and maintained. For example, an inaccurate meter can lead to motor failure or compromised performance. Many professionals overlook this. They focus solely on price instead of quality.

However, understanding torque measurement is imperative. Each motor application demands different specifications. Thus, you must evaluate the features of the torque meter for motor carefully. Blindly purchasing can lead to regrets later. Features like accuracy, range, and data output should guide your decision. Remember, the right tool can enhance your motor's lifespan and reliability.

Understanding Torque Meter Specifications and Their Relevance to Motors

When selecting a torque meter, understanding its specifications is crucial. Torque meters measure rotational force in motors. Key specifications include measurement range, accuracy, and resolution. A high measurement range allows versatility in applications. Accuracy ensures reliable readings. Think about the type of motor. Do you need a high torque reading for heavy machinery or a low one for precision tasks?

In addition, consider how the torque meter interfaces with your motor. Some meters connect via cables, while others are wireless. The ease of data transfer can save time. Not all torque meters are user-friendly. Some require extensive training or detailed manuals, which can be a barrier. Feedback from other users can provide insight into these aspects.

Battery life and maintenance also matter. A meter that needs constant charging may disrupt workflow. Reflecting on these factors can guide your decision. There is no one-size-fits-all solution. Each situation demands careful consideration of the motor's needs and the meter's specifications.

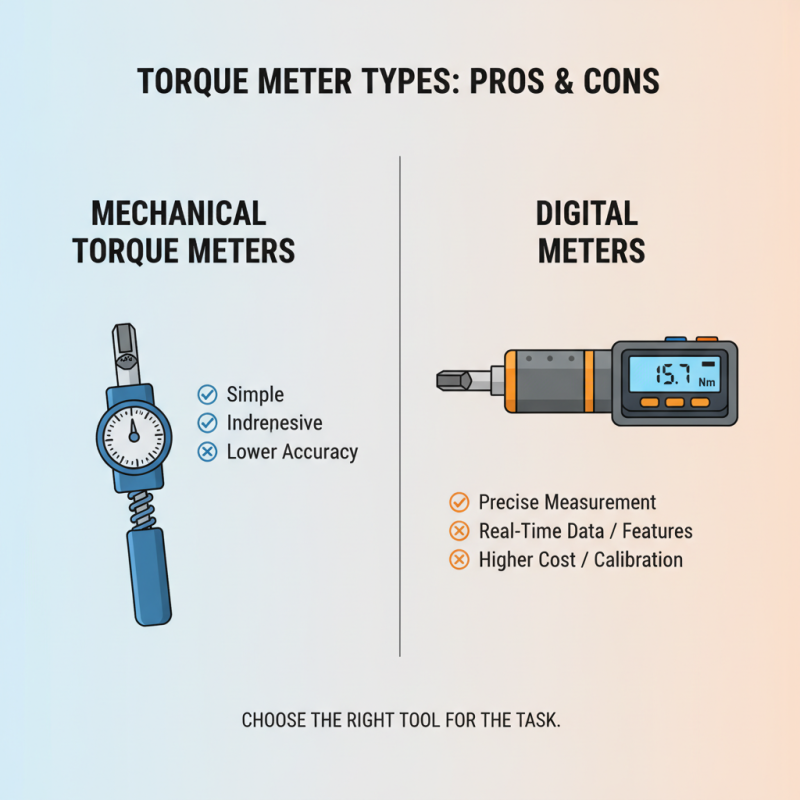

Key Types of Torque Meters: Benefits and Limitations Explained

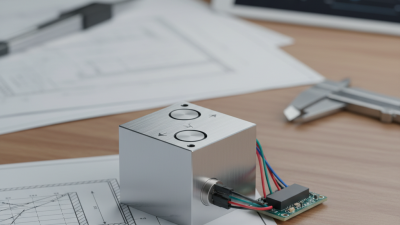

When selecting a torque meter, it's essential to understand the different types available and their pros and cons. Mechanical torque meters are simple and inexpensive. They are often used for basic applications. However, they can lack accuracy in high-precision tasks. Digital torque meters provide precise measurements and real-time data. They are user-friendly and often come with advanced features. Yet, they can be more expensive and may require regular calibration.

Another option is the beam-type torque meter, which offers reliable readings. These are great for both light and heavy-duty applications. However, users often find them less convenient. They can be bulkier and harder to handle in some situations. Finally, consider the capability of the meter. Some torque meters are designed for specific tasks, while others offer versatility. Balancing your needs with these features is crucial. Think about your regular tasks and the measurements required. Do you need something portable, or is precision your top concern? Each choice has reflections that vary from person to person.

Calibration Standards: Importance for Accurate Torque Measurement

Calibration standards are crucial in achieving accurate torque measurement for motors. In the engineering field, precision is key. According to a report by the National Institute of Standards and Technology (NIST), improper calibration can lead to measurement errors exceeding 10%. This discrepancy is significant in applications requiring high precision like automotive and aerospace sectors.

Ensuring your torque meter is calibrated according to recognized standards is vital. ISO 6789 is one widely accepted standard. It emphasizes the importance of periodic checks. Regular calibration helps maintain reliability in torque measurements. Ignoring calibration can lead to under or over-tightening. This can cause equipment failure or unsafe conditions.

Moreover, the environment affects calibration. Temperature fluctuations or humidity levels can influence torque readings. A recent study published in the Journal of Mechanical Engineering found that environmental factors contributed to a 5% variance in torque measurements. Such variations highlight the need for constant monitoring and re-calibration. Making mistakes in torque measurement can have real-world repercussions. Proper calibration acts as a safeguard against these pitfalls.

How to Choose the Best Torque Meter for Your Motor Needs?

| Torque Meter Type | Measurement Range (Nm) | Accuracy (%) | Calibration Standard | Price (USD) |

|---|---|---|---|---|

| Digital Torque Meter | 0-100 | ±1.5% | ISO 6789 | 150 |

| Mechanical Torque Wrench | 5-200 | ±3.0% | ASTM F889 | 80 |

| Torque Transducer | 0-500 | ±0.5% | NIST | 500 |

| Torque Analyzer | 0-1000 | ±1.0% | ISO 5725 | 900 |

Selecting the Right Torque Range for Your Motor Application

Selecting the right torque range for your motor application is crucial. The torque meter must match the needs of your specific motor. Too low a range can lead to inaccurate readings. Conversely, too high a range may not provide the resolution you need. Getting it right ensures reliability in performance.

When assessing your motor's requirements, consider the power output and speed. A motor generating 100 Nm should ideally have a torque meter that can accurately measure around that value. Remember, tolerance levels in both instruments and applications are essential.

Tips: Always verify the specifications before purchase. Consult with experts if unsure about the torque range. Opt for a torque meter with a display that’s easy to read and understand. It's better to invest in quality upfront than to deal with inaccuracies later. Test your setup under various conditions to ensure it meets all expectations.

Torque Meter Selection for Motor Applications

This chart illustrates the torque range requirements for various motor applications. It highlights the recommended torque meters based on the torque demand of different types of motors, enabling users to select the most suitable device for their needs.

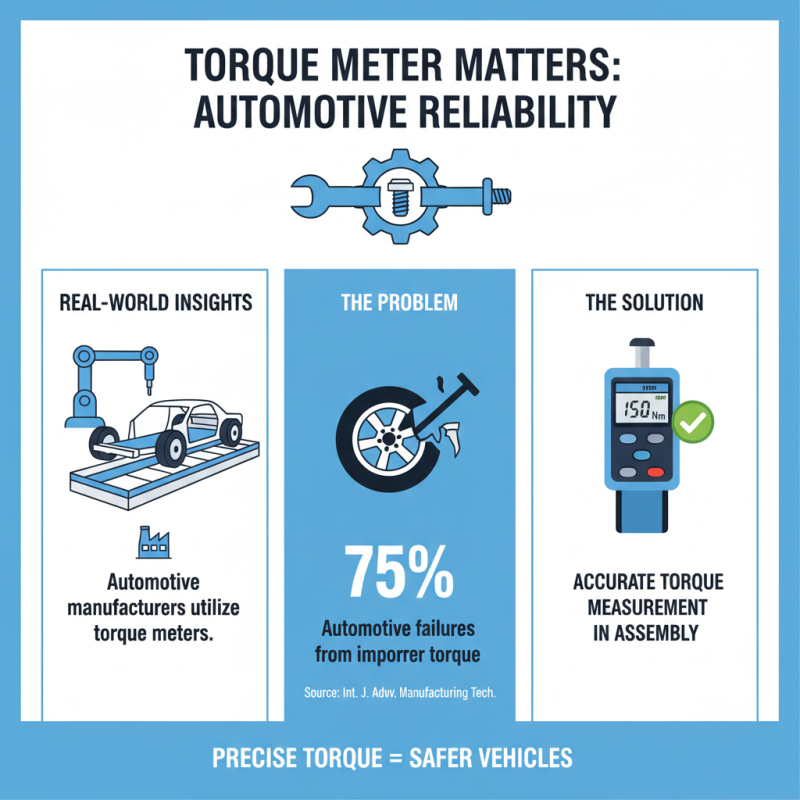

Real-World Applications: Case Studies of Torque Meters in Use

When selecting a torque meter, real-world applications offer valuable insights. Many industries utilize torque meters extensively. For example, automotive manufacturers rely on precise torque measurements. According to a report by the International Journal of Advanced Manufacturing Technology, 75% of automotive failures stem from improper torque. These failures highlight the importance of accurate torque measurement in the assembly line.

In the aerospace sector, torque meters play a critical role. Assembly of aircraft components demands exact specifications. In a case study, a major aircraft manufacturer reported that using advanced torque meters reduced assembly errors by 30%. This improvement directly enhances safety and reliability. However, some manufacturers struggle with outdated equipment. This raises questions about efficiency and accountability in a high-stakes industry.

Consider the energy sector as another example. Wind turbines require specific torque values for optimal performance. A study by the American Wind Energy Association revealed that up to 20% of maintenance costs resulted from inadequate torque management. Adopting modern torque meters can mitigate these costs. Yet, many operators still overlook their importance, resulting in potential lapses in energy efficiency and sustainability.

Related Posts

-

How to Select the Best Rotary Torque Transducer for Your Industrial Needs

-

Understanding the Importance of Shaft Torque Sensors in Modern Engineering Practices

-

What is a Torque Meter for Motor and How Does It Work?

-

What is a Rotary Torque Sensor and How Does it Work?

-

2025 How to Choose the Best Biaxial Load Cell for Your Application

-

Why Choose a 3-Axis Force Sensor for Your Projects?