sales@loadcellsensor.com

sales@loadcellsensor.com

Innovative Applications of Compression Force Sensors in Smart Manufacturing Technologies

In the realm of smart manufacturing technologies, the integration of advanced sensors plays a pivotal role in enhancing efficiency and precision. Among these, the Compression Force Sensor stands out as a critical component that enables manufacturers to monitor and control processes in real time. These sensors are designed to measure the amount of force applied during various manufacturing operations, providing valuable data that can be used to ensure product quality, optimize production lines, and improve overall operational performance.

This innovative application of compression force sensing technology not only supports the automation of manufacturing processes but also facilitates the adoption of Industry 4.0 practices. As industries strive for smarter, more connected solutions, understanding the multifaceted applications of Compression Force Sensors becomes essential for leveraging their capabilities to achieve sustained competitive advantages in a rapidly evolving market landscape.

In the realm of smart manufacturing technologies, the integration of advanced sensors plays a pivotal role in enhancing efficiency and precision. Among these, the Compression Force Sensor stands out as a critical component that enables manufacturers to monitor and control processes in real time. These sensors are designed to measure the amount of force applied during various manufacturing operations, providing valuable data that can be used to ensure product quality, optimize production lines, and improve overall operational performance.

This innovative application of compression force sensing technology not only supports the automation of manufacturing processes but also facilitates the adoption of Industry 4.0 practices. As industries strive for smarter, more connected solutions, understanding the multifaceted applications of Compression Force Sensors becomes essential for leveraging their capabilities to achieve sustained competitive advantages in a rapidly evolving market landscape.

Overview of Compression Force Sensors in Smart Manufacturing

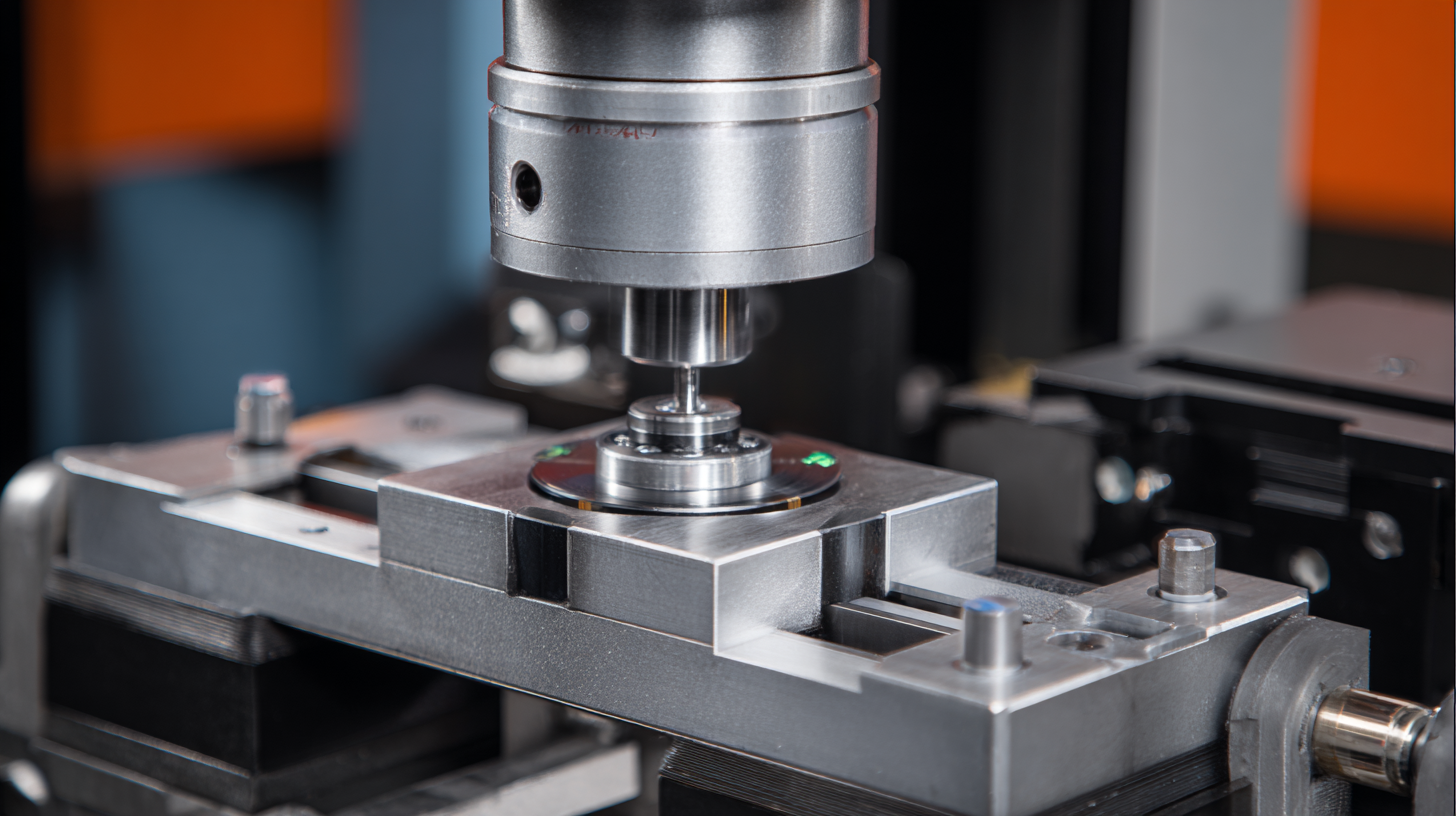

Compression force sensors are critical components in the realm of smart manufacturing, playing a pivotal role in enhancing process efficiency and product quality. These sensors measure the amount of force applied to an object, providing real-time data that can be utilized for monitoring and control purposes. By integrating compression force sensors into manufacturing systems, companies can optimize operations, ensuring that machinery operates within safe parameters while minimizing waste and downtime. This integration allows for a more automated and responsive production environment, as sensors can trigger alerts and adjustments based on the force readings.

In addition to improving operational efficiency, compression force sensors contribute significantly to quality control in smart manufacturing. They enable precise measurements during the assembly process, ensuring that components are assembled with the correct force and pressure. This accuracy is crucial in preventing defects and enhancing the overall reliability of products. Furthermore, the data generated by these sensors can be analyzed to identify trends and patterns, leading to informed decision-making and continuous improvement in manufacturing practices. As industries increasingly adopt smart technologies, the role of compression force sensors will continue to evolve, becoming integral to achieving advanced manufacturing goals.

Benefits of Integrating Compression Force Sensors in Production Lines

The integration of compression force sensors in production lines has revolutionized smart manufacturing technologies by enhancing accuracy and efficiency. These sensors monitor the force applied during various stages of the production process, ensuring that components are assembled with the correct pressure. This real-time monitoring leads to improved quality control and reduces the likelihood of defects in the final products, ultimately saving time and resources.

Moreover, the use of compression force sensors contributes to predictive maintenance strategies. By analyzing the force data collected from production machinery, manufacturers can identify patterns that indicate wear or impending failure. This proactive approach allows for timely interventions, minimizing downtime and extending the lifespan of equipment. By integrating these sensors, companies can not only streamline their operations but also achieve a more sustainable manufacturing process with reduced waste.

Real-time Monitoring and Data Analysis through Compression Force Sensors

Compression force sensors are pivotal in facilitating real-time monitoring and data analysis within smart manufacturing environments. As the industry embraces the

Internet of Things (IoT) and Industry 4.0 concepts, these sensors enable seamless communication between machines and systems, providing

critical insights into operational performance. According to a report by Research and Markets, the global market for force sensors is projected to reach

$4.60 billion by 2025, driven by increased demand for automation and data-driven decision-making in manufacturing processes.

By employing compression force sensors, manufacturers can achieve heightened accuracy in load measurement and application. This real-time data not only enhances quality control but also facilitates predictive maintenance,

thereby reducing downtime and operational costs. Industry data suggests that manufacturers using smart sensors can reduce operational downtime by up to 15%, showcasing the significant

impact of deploying these technologies. With advanced analytics and machine learning algorithms capable of processing vast amounts of data, companies can identify trends and anomalies, optimizing production efficiency and enhancing overall equipment effectiveness.

Case Studies: Successful Implementation in Smart Manufacturing Settings

In recent years, smart manufacturing technologies have increasingly integrated compression force sensors to enhance operational efficiency and product quality. For instance, a notable case study involved an automotive manufacturer that implemented these sensors on assembly lines to monitor torque applied to bolts. This real-time monitoring allowed for immediate adjustments, significantly reducing the risk of component failure and increasing overall safety.

Another successful application can be observed in the electronics industry, where a company utilized compression force sensors during the packaging process. By measuring the pressure applied to sensitive components, they ensured that each package met stringent quality standards, leading to a 20% decrease in product returns due to damage. This not only saved costs but also improved customer satisfaction.

**Tip:** When implementing compression force sensors, consider integrating them with existing manufacturing execution systems to leverage data analytics for proactive decision-making.

**Tip:** Always conduct a pilot test before full-scale implementation. This allows for adjustments based on real-world feedback, ensuring the system works effectively in your unique manufacturing environment.

Innovative Applications of Compression Force Sensors in Smart Manufacturing Technologies - Case Studies: Successful Implementation in Smart Manufacturing Settings

| Application Area | Technology Used | Key Benefits | Implementation Date | Performance Improvement |

|---|---|---|---|---|

| Quality Control | Digital Compression Sensors | Increased accuracy in defect detection | 2022 | 25% reduction in defects |

| Assembly Line Monitoring | IoT-enabled Force Sensors | Real-time monitoring and alerts | 2023 | 15% increase in throughput |

| Material Handling | Wireless Compression Sensors | Improved safety and efficiency | 2021 | 20% reduction in accidents |

| Robotic Process Automation | Smart Sensors Network | Enhanced robotic precision | 2023 | 30% improvement in task performance |

| Product Testing | High-precision Compression Sensors | Faster testing cycles | 2022 | 25% decrease in testing time |

Future Trends and Innovations in Compression Force Sensor Technology

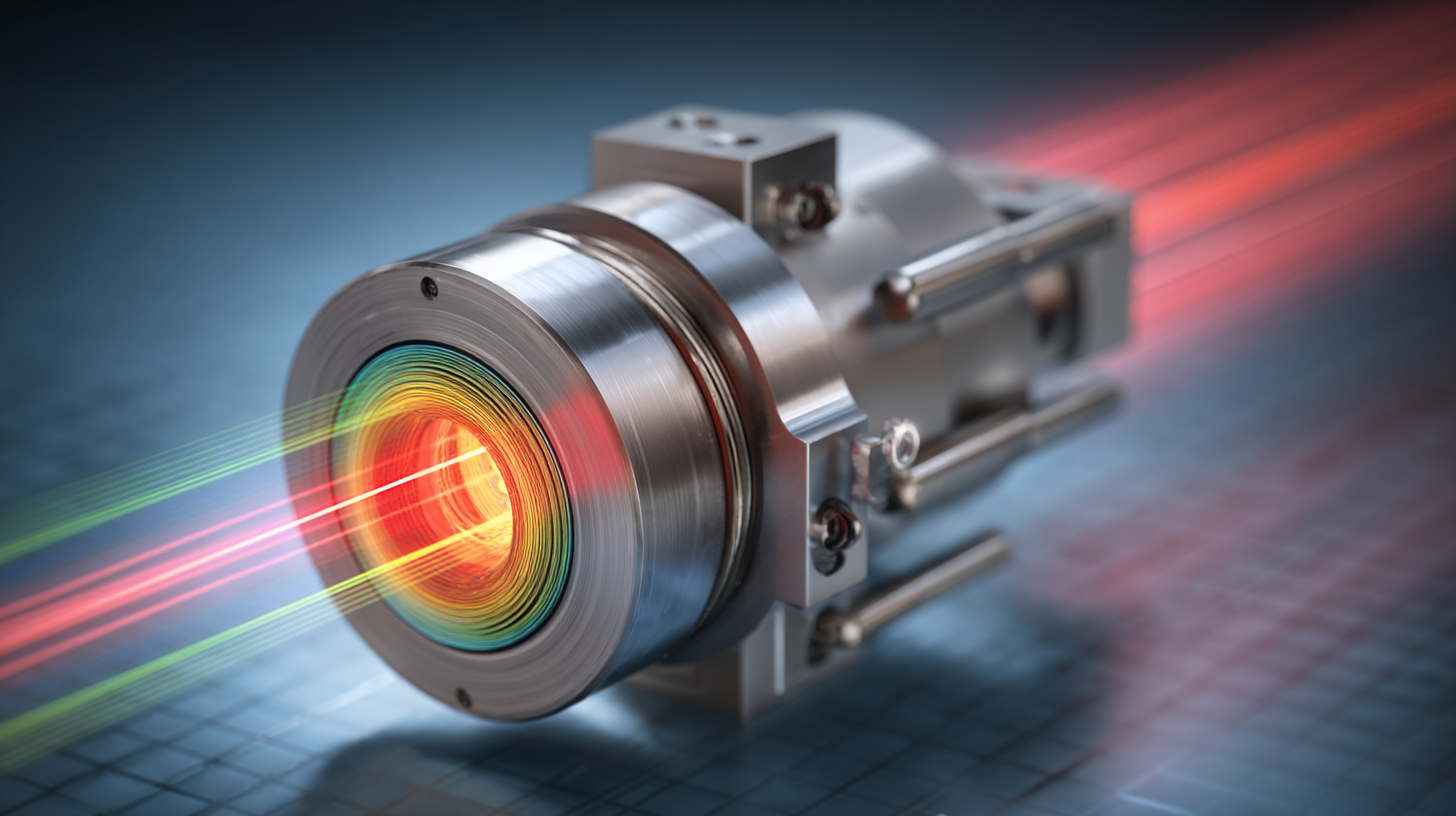

The future of compression force sensor technology in smart manufacturing is set to advance with several innovative trends on the horizon. As industries increasingly adopt automation and the Internet of Things (IoT), the integration of compression force sensors will enhance precision in quality control and robotic operations. These sensors are becoming more sophisticated, offering real-time data analysis that allows manufacturers to monitor and adjust processes instantly. With advancements in materials science, new sensor designs are emerging, which not only provide better accuracy but also increase resilience to environmental factors, expanding their application range.

Moreover, the rise of artificial intelligence and machine learning is paving the way for smart compression force sensors to evolve further. By leveraging data analytics, manufacturers can identify patterns and predict potential failures, thereby minimizing downtime and enhancing productivity. Wireless connectivity is another significant trend, enabling seamless communication between sensors and manufacturing systems. This capability allows for the remote monitoring of force applications across various stages of production, facilitating smarter decision-making and resource optimization. As these technologies converge, the role of compression force sensors will be pivotal in shaping the future of smart manufacturing.

Related Posts

-

12 Expert Tips for Maximizing Efficiency with Compression Force Sensors

-

10 Compelling Reasons to Choose Force Sensors for Your Next Project

-

5 Key Advantages of Choosing the Best Force Transducer for Your Applications

-

Understanding the Key Technical Specifications of the Best Force Transducer and How to Choose the Right One

-

Top Strategies for Leveraging Force Transducer Technology in Global Procurement

-

Explore Cutting-Edge Weight Sensors at the Record-Breaking 137th Canton Fair!