sales@loadcellsensor.com

sales@loadcellsensor.com

Top Applications of Donut Load Cells in 2025 You Should Know About

In the rapidly evolving landscape of industrial measurement and weighing technology, the **Donut Load Cell** has emerged as a pivotal component, particularly in environments where precision and reliability are paramount. According to a recent industry report by Research and Markets, the global load cell market is projected to reach USD 2.4 billion by 2025, with the application of donut load cells expected to account for a significant share due to their unique design and superior performance. These load cells, characterized by their toroidal shape, provide exceptional accuracy in weight measurement while offering robust resistance to external forces, making them ideal for a variety of applications including industrial automation, aerospace, and automotive sectors.

As industries continue to adopt advanced technologies in their operations, the versatility of the donut load cell becomes increasingly evident. The ability to measure tensile and compressive loads with remarkable fidelity allows for improved quality control and enhanced safety standards across different applications. Furthermore, the growing demand for sensor-based solutions in IoT and smart factory initiatives underscores the fundamental role that donut load cells will play in future developments. By 2025, it is anticipated that these load cells will not only streamline operations but also facilitate the integration of real-time data analytics, driving efficiency and innovation in diverse sectors.

Overview of Donut Load Cells and Their Functionality

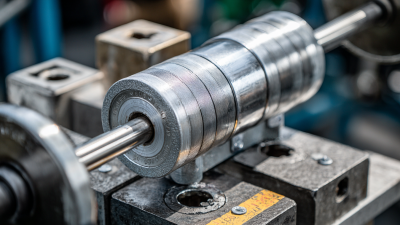

Donut load cells are specialized sensors designed to measure force or weight, distinguished by their unique circular design. These sensors operate based on the principle of strain gauges, which detect deformation when a load is applied. The compact, low-profile nature of donut load cells makes them ideal for applications where space is a constraint. Their design allows for 360-degree load measurement, providing accurate data regardless of the force's direction, which is particularly useful in environments where loads may vary unpredictably.

When utilizing donut load cells, it is essential to ensure proper alignment during installation. Misalignment can lead to inaccurate measurements and potentially compromise the integrity of the sensor. Additionally, regular calibration is crucial to maintain precision and reliability in measurements.

Tips: Always consider environmental factors, such as temperature and humidity, as they can affect the performance of load cells. Properly isolating the load cell from vibration sources will help maintain functionality in dynamic settings. For those new to implementing donut load cells, consulting with professionals for installation and maintenance strategies can lead to optimal performance and longevity of the equipment.

Key Industries Utilizing Donut Load Cells in 2025

In 2025, various key industries are set to leverage the unique advantages of donut load cells for improved accuracy and efficiency in measurement. The manufacturing sector, particularly in automotive and aerospace, stands out as a primary user. According to a recent market analysis report, approximately 45% of load cell applications in manufacturing now utilize advanced sensors like donut load cells due to their ability to handle dynamic loads and their compact design. This is particularly crucial in environments where space is limited, allowing for precise measurements without sacrificing structural integrity.

Another significant industry utilizing donut load cells is the medical field, where these devices are increasingly being employed in high-precision surgical tools and patient monitoring systems. Reports indicate that the demand for load cells in medical applications is projected to grow by over 25% by the end of the decade, as hospitals and clinics focus on improving patient outcomes through enhanced monitoring and automated systems. Donut load cells provide critical feedback in these applications, ensuring that weight measurements are reliable and consistent, which is essential for both patient safety and operational efficiency in medical devices.

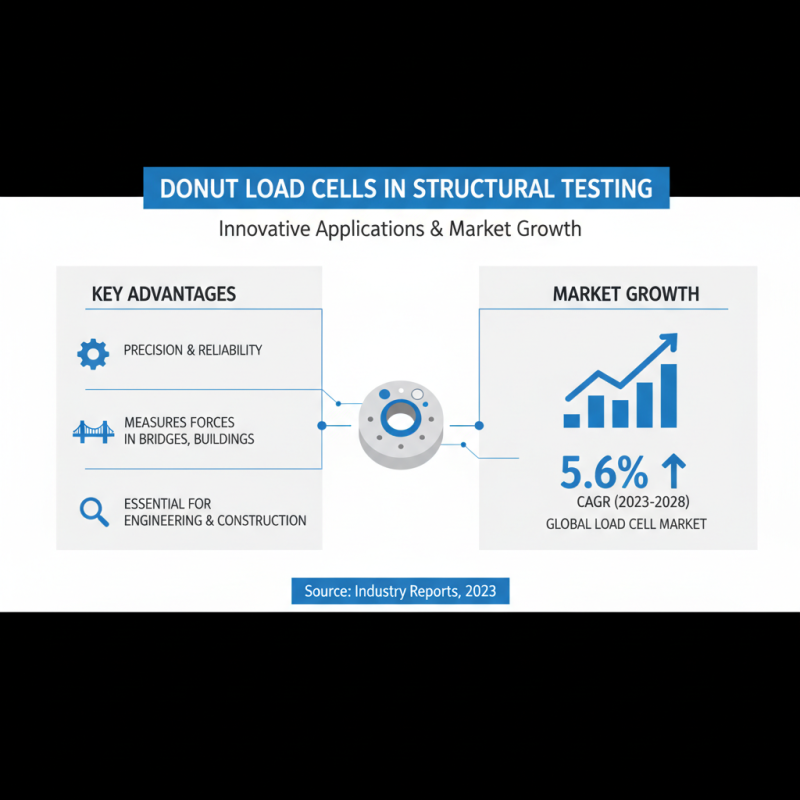

Innovative Applications of Donut Load Cells in Structural Testing

The innovative applications of donut load cells in structural testing are becoming increasingly essential in the engineering and construction sectors. These devices offer exceptional precision and reliability when measuring forces and loads in various structural components, from bridges to high-rise buildings. According to recent industry reports, the global load cell market is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2028, highlighting the rising demand for advanced load measurement technologies.

One prominent application of donut load cells is in the assessment of load-bearing structures during seismic testing. By accurately measuring the stresses and strains experienced during seismic events, engineers can gather critical data to enhance the safety and resilience of structures. Additionally, donut load cells are widely used in load testing scenarios to determine the performance limits of newly constructed or retrofitted structures, ensuring compliance with safety standards and regulations.

Tip: When selecting load cells for structural testing, consider factors such as capacity, accuracy, and environmental conditions. It’s crucial to choose models with a proven track record in real-world applications to ensure reliable data collection.

Moreover, the advancements in wireless technology are paving the way for donut load cells to be integrated with IoT systems, allowing for real-time data monitoring and analysis. This innovation significantly improves the efficiency of structural assessments, enabling engineers to respond swiftly to any anomalies detected during testing. As the industry continues to evolve, the versatility and functionality of donut load cells will undoubtedly play a vital role in future structural integrity evaluations.

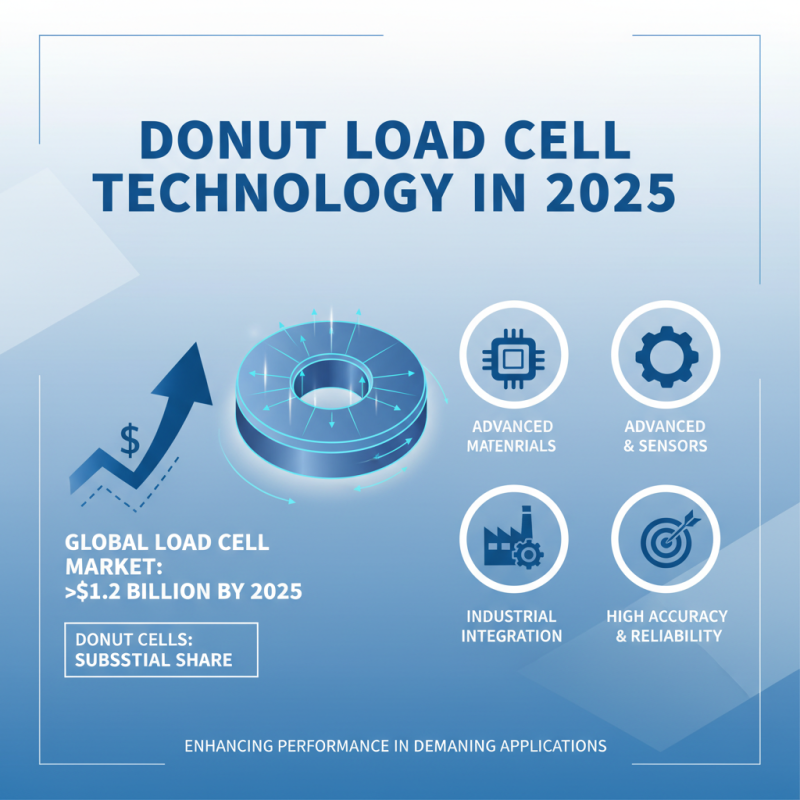

Advancements in Technology Enhancing Donut Load Cell Performance

The advancements in technology have significantly enhanced the performance of donut load cells, making them integral to various industries in 2025. These load cells, known for their unique design that allows for precise measurement of axial loads, have benefited from improvements in materials and sensor technologies. Recent reports from leading industry analysts indicate that the global market for load cells is expected to reach over $1.2 billion by 2025, with donut load cells accounting for a substantial share due to their high accuracy and reliability in demanding applications.

One of the noteworthy technological advancements is the incorporation of digital signal processing (DSP) technologies, which enable real-time data analysis and increased measurement resolution. This enhancement allows donut load cells to provide highly accurate load measurements even in dynamic conditions, such as heavy machinery operations and on-site construction. According to a 2023 study, the integration of DSP in load cells is projected to reduce error margins by up to 15%, thereby driving increased adoption in sectors requiring stringent safety and compliance standards, like aerospace and automotive manufacturing.

Furthermore, innovations in wireless communication technologies have enabled more flexible and efficient load monitoring solutions. By utilizing IoT capabilities, donut load cells can now transmit data wirelessly, allowing for remote monitoring and real-time feedback. A survey from a leading technology research firm found that systems employing wireless donut load cells are 30% more efficient in operational settings compared to traditional wired systems. This shift not only streamlines workflows but also enhances the overall safety and functionality of systems where load management is critical.

Future Trends and Market Growth for Donut Load Cells in 2025

In 2025, the market for donut load cells is expected to experience significant growth due to their versatile applications across various industries. One of the primary drivers of this growth is the increasing demand for precision measurement in sectors such as manufacturing, aerospace, and automotive. As industries strive for enhanced efficiency and quality control, donut load cells provide the ideal solution for measuring forces and weights in compact spaces. Their unique design allows for easy integration into existing systems, which is crucial for companies looking to upgrade their facilities without extensive modifications.

Future trends indicate a shift towards more advanced technologies in load cell applications. The incorporation of IoT technology in donut load cells will facilitate real-time data monitoring and analytics, allowing businesses to optimize operations. Additionally, as automation continues to gain traction, the demand for smart load sensing solutions will rise. These innovations will not only make load cells more efficient but also open new avenues for their use in emerging sectors, such as renewable energy and robotics. As these trends unfold, it is essential for companies to stay ahead of the curve and leverage the full potential of donut load cells to enhance their operational capabilities.

Related Posts

-

5 Essential Tips for Choosing the Right Tension Compression Load Cell

-

Exploring the Future of Load Cells: Innovations Beyond the Best Bending Beam by 2025

-

Understanding the Science Behind Compression Load Cells: Optimizing Precision in Measurements

-

Rise of Chinese Manufacturing in Micro Load Cells Amidst US China Tariff Challenges

-

Top 10 Micro Load Cell Manufacturers from China at the 137th Canton Fair

-

The Ultimate Guide to Selecting the Best Through Hole Load Cell for Your Needs