sales@loadcellsensor.com

sales@loadcellsensor.com

5 Essential Tips for Choosing the Right Tension Compression Load Cell

When selecting the right Tension Compression Load Cell, it’s essential to navigate through an array of options that meet specific industrial demands. According to a market research report by Grand View Research, the global load cell market is expected to reach $3.18 billion by 2025, driven by the increasing demand for precision and reliability in weighing applications across various sectors including manufacturing, automotive, and aerospace. Understanding the fundamental features and capabilities of tension compression load cells is crucial, as different applications require varying levels of accuracy and load capacities. This guide will outline five essential tips to consider in your selection process, ensuring that you choose a load cell that not only meets your operational requirements but also enhances overall system performance and efficiency.

Factors to Consider When Selecting a Tension Compression Load Cell Type

When selecting a tension compression load cell, several crucial factors must be considered to ensure optimal performance for your specific application. Firstly, understanding the load cell's capacity is vital. Make sure to choose a load cell with a capacity that meets or exceeds the maximum expected load. Under-specifying can lead to failure or inaccurate readings, while over-specifying may result in unnecessary costs. Additionally, consider the operating environment; factors like temperature, humidity, and potential exposure to chemicals can significantly impact performance. Choosing a load cell designed to withstand the specific conditions in which it will operate can enhance reliability and longevity.

Another important aspect to evaluate is the output signal type. Load cells commonly offer analog output, digital output, or a combination of both. The choice between these options depends on your data acquisition system and how you intend to process the readings. For applications requiring high precision and real-time data, digital load cells may be preferable due to their increased accuracy and reduced susceptibility to noise. Furthermore, gauge the mounting options and physical dimensions of the load cell, as they need to fit seamlessly within your existing setup without alteration. By considering these factors, you can make a well-informed decision, ultimately ensuring that the chosen tension compression load cell meets your performance criteria effectively.

Understanding the Key Specifications of Tension Compression Load Cells

When selecting a tension compression load cell, understanding its key specifications is fundamental for ensuring optimal performance. One of the critical specifications to consider is the loading capacity, which is often measured in pounds or kilograms. Reports indicate that high-capacity load cells can support loads exceeding 100,000 pounds, making them suitable for heavy industrial applications. It's essential to match the load cell's capacity with the expected load to prevent overloading and potential damage.

Another important parameter is the accuracy or precision of the load cell, often expressed as a percentage of full scale. Industry standards indicate that high-quality load cells can achieve accuracies within ±0.1% to ±0.01%. Selecting a load cell with the appropriate accuracy is vital, especially in applications where precise measurements are critical, such as in aerospace or medical device manufacturing. Additionally, factors such as temperature compensation, environmental ratings, and response time should also be evaluated to ensure the selected load cell meets all operational requirements and maintains performance reliability across diverse conditions.

5 Essential Tips for Choosing the Right Tension Compression Load Cell

| Specification | Description | Importance |

|---|---|---|

| Capacity | The maximum load that the load cell can measure | Critical for ensuring the load cell can handle the expected loads |

| Accuracy | The degree to which the load cell's output corresponds to the actual load | Essential for precision measurements in applications |

| Output Signal | The type of signal produced (e.g., mV/V, digital, etc.) | Important for compatibility with data acquisition systems |

| Temperature Range | The operating temperature limits for the load cell | Crucial for stability and performance in varying environmental conditions |

| Material | The construction material of the load cell (e.g., aluminum, stainless steel) | Affects durability, weight, and suitability for environments |

Importance of Load Cell Accuracy: Industry Standards and Performance Metrics

When selecting a tension compression load cell, accuracy is paramount. The significance of load cell accuracy extends beyond mere functionality; it directly impacts the reliability of data and overall performance in various applications. Adhering to industry standards such as ISO, OIML, and ASTM ensures that the load cell meets stringent accuracy requirements, which is crucial for industries like manufacturing, aerospace, and automotive. These standards provide a framework for testing and calibration, ensuring that load cells can deliver precise measurements over time, even under varying environmental conditions.

Performance metrics, such as non-linearity, hysteresis, and repeatability, are essential factors in evaluating load cell accuracy. A load cell that shows minimal non-linearity will deliver measurements that closely match actual load conditions across its operating range. Hysteresis, the difference in measurement when the load is applied versus when it's removed, should also be low to ensure consistent results. Additionally, a high repeatability index indicates that the load cell will provide similar readings under the same conditions each time, enhancing reliability.

When choosing a load cell, scrutinizing these performance metrics in conjunction with industry standards can lead to informed decisions that enhance operational efficiency and data integrity.

Different Applications of Tension Compression Load Cells Across Industries

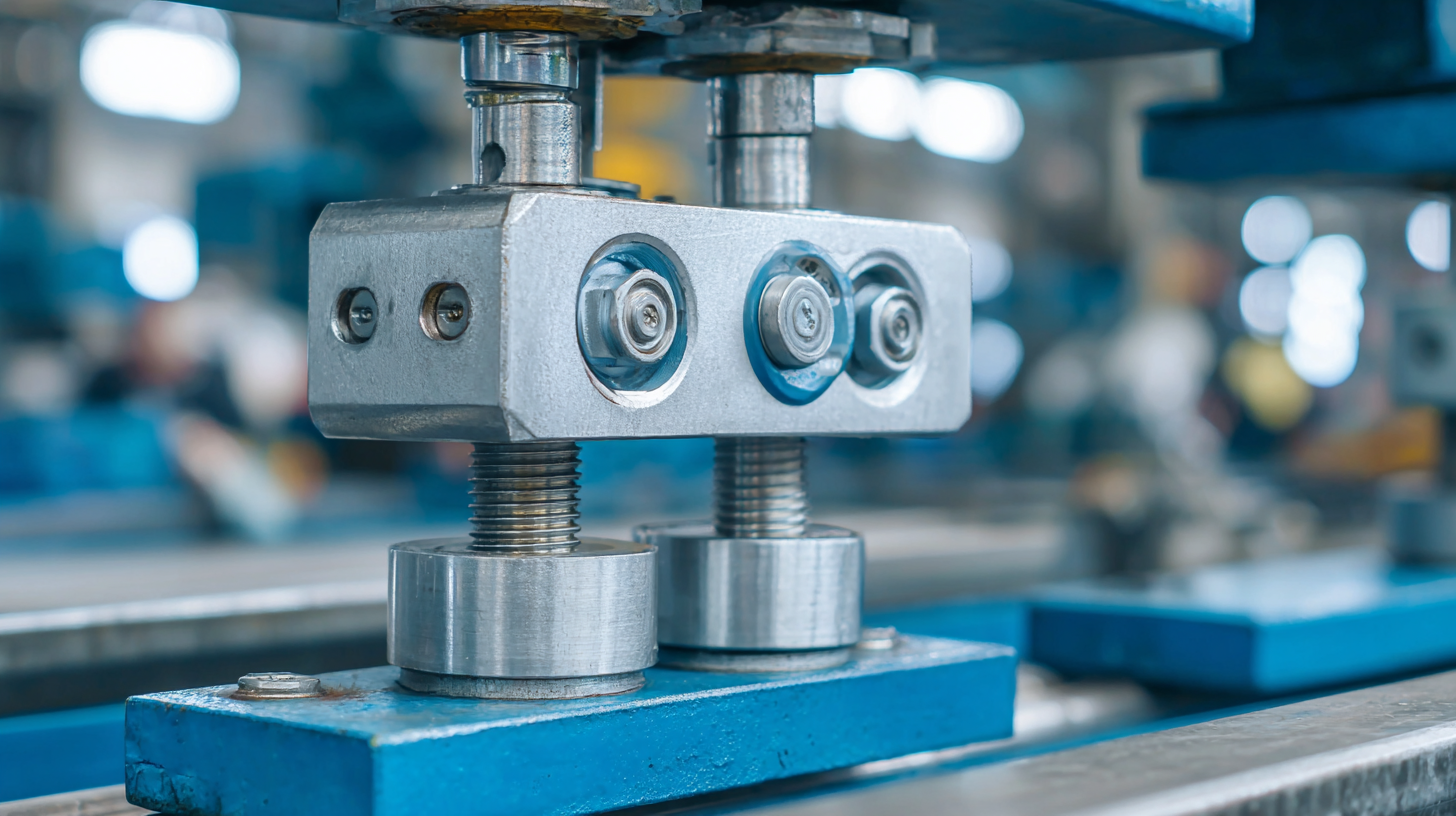

Tension compression load cells are crucial in various industries, providing accurate measurements necessary for effective operations. In manufacturing, these load cells are employed to monitor the weight of raw materials and finished products. By ensuring that the correct amounts are processed, manufacturers can optimize production efficiency and maintain quality control, preventing costly errors that can arise from over or underweight products.

In the construction industry, tension compression load cells play a vital role in structural health monitoring. They are used to measure forces on bridges, dams, and buildings, allowing engineers to assess the integrity of structures over time. This application not only ensures the safety of the structures but also helps in planning maintenance activities, thereby extending the lifespan of critical infrastructure. Additionally, load cells are widely utilized in automotive testing where they assess the strength and performance of various components under different loads, ensuring that vehicles meet safety standards before reaching the market.

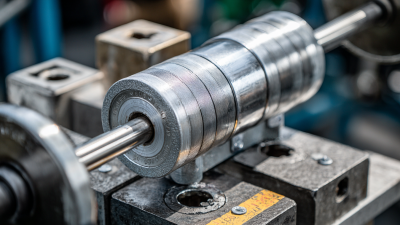

Comparative Analysis of Load Cell Technologies: Strain Gauge vs. Capacitive Types

When selecting a tension compression load cell, understanding the technologies at play is vital. The two predominant types, strain gauge and capacitive load cells, exhibit distinct characteristics that can significantly influence performance in various applications. Strain gauge load cells operate by measuring the deformation (strain) of a material when subjected to stress, which translates to load measurement. According to a report from MarketsandMarkets, the global strain gauge load cell market is projected to reach $1.5 billion by 2025, underscoring their widespread usage due to their accuracy and cost-effectiveness.

On the other hand, capacitive load cells function by measuring changes in capacitance caused by applied forces. These load cells are typically praised for their higher sensitivity, making them ideal for precise applications. A study published in the Journal of Applied Mechanics found that capacitive technologies can achieve an accuracy rate of over 0.1% in controlled environments, albeit at a higher cost compared to their strain gauge counterparts. As industries increasingly prioritize precision, understanding these differences is crucial for choosing the right load cell to meet specific load measurement needs.

Comparative Analysis of Load Cell Technologies

This chart compares the performance of Tension Compression Load Cell technologies, focusing on Strain Gauge and Capacitive types across different parameters such as Accuracy, Cost, Sensitivity, Temperature Range, and Linearity.

Related Posts

-

Exploring the Future of Load Cells: Innovations Beyond the Best Bending Beam by 2025

-

Top 10 Micro Load Cell Manufacturers from China at the 137th Canton Fair

-

Unlocking Efficiency: Key Advantages of Utilizing Compression Load Cells in Industrial Applications

-

Discovering the Best Compression Load Cells: A Global Buyer’s Guide for Performance and Reliability

-

Exploring Alternative Load Cell Solutions for Optimizing Tensile and Compressive Testing

-

7 Unique Benefits of Compression Type Load Cells for Modern Industries