sales@loadcellsensor.com

sales@loadcellsensor.com

5 Essential Tips for Choosing the Right Tension Sensor for Your Applications

In today's rapidly advancing industrial landscape, the choice of a Tension Sensor is critical for optimizing performance and ensuring the reliability of various applications. According to a recent report by MarketsandMarkets, the global tension sensor market is projected to reach $2.1 billion by 2025, growing at a significant CAGR of 5.9%. This impressive growth can be attributed to the increasing demand for precision measurement in sectors such as automotive, aerospace, and manufacturing. With diverse options available, selecting the right tension sensor can be daunting. Factors such as measurement range, environmental conditions, and integration capabilities must be carefully considered to enhance system efficiency and lifespan. This ultimate guide will provide you with five essential tips to navigate the complexities of choosing the ideal tension sensor for your specific needs, ensuring optimal performance and reliability in your applications.

Key Factors to Consider When Selecting Tension Sensors for Your Needs

When selecting a tension sensor for your specific applications, it's vital to consider several key factors that will ensure you choose the right device. First and foremost, you must evaluate the sensor's range and resolution. A tension sensor's measurement capacity should align with your operational requirements, ensuring it can accurately measure the tension levels without saturation or underperformance.

Another important consideration is the environmental compatibility of the sensor. Factors such as temperature, humidity, and exposure to chemicals can significantly impact the sensor's longevity and accuracy. Selecting a tension sensor that can withstand the specific conditions of your application will help maintain performance over time.

Lastly, consider the ease of integration and compatibility with existing systems. Check if the sensor can easily connect to your data acquisition systems or operational controls. This will not only simplify installation but also enhance the overall performance of your setup. By carefully considering these factors, you can select a tension sensor that is not only effective but also durable and seamless in operation.

5 Essential Tips for Choosing the Right Tension Sensor for Your Applications

| Factor | Description | Example Applications |

|---|---|---|

| Load Capacity | The maximum load the sensor can accurately measure. | Robotics, Manufacturing |

| Accuracy | The degree to which the sensor's measurements are close to the true value. | Material Testing, Quality Control |

| Environmental Resistance | Ability to withstand harsh conditions, such as temperature and humidity. | Outdoor Equipment, Aerospace |

| Response Time | The time taken for the sensor to respond to changes in load. | Dynamic Testing, Automated Systems |

| Installation Type | How the sensor is mounted or integrated into the system. | Construction, Automotive |

Understanding Different Types of Tension Sensors and Their Applications

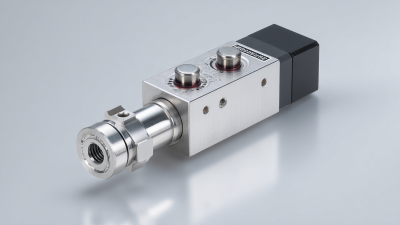

When selecting a tension sensor for your application, it is crucial to understand the different types available on the market, as each type serves unique purposes. Commonly used tension sensors include load cells, piezoelectric sensors, and strain gauges. Load cells measure the force exerted on them and are ideal for applications requiring high precision. Piezoelectric sensors, on the other hand, can detect rapid changes in tension, making them suitable for dynamic applications where immediate response is necessary. Strain gauges are typically used for static measurements, providing reliable data for applications like structural monitoring.

Moreover, considering the environment in which the tension sensor will operate is vital. For instance, if the sensor will be subjected to extreme temperatures or harsh conditions, opting for a sensor with a protective casing or selecting materials that withstand corrosion may be essential. Additionally, applications in industries like automotive, manufacturing, or marine operations require sensors that can handle varying degrees of tension without compromising accuracy. Understanding these different types and their specific applications will guide you in making an informed decision tailored to your needs, ensuring optimal performance and reliability in your projects.

5 Essential Tips for Choosing the Right Tension Sensor for Your Applications

Evaluating Sensor Accuracy and Calibration Standards

When selecting a tension sensor for your applications, the evaluation of sensor accuracy and calibration standards is paramount. The performance of your sensor relies heavily on its ability to provide precise readings, which means understanding its calibration procedures is crucial. Calibration ensures that the measurements you receive are consistent and accurate over time. Different types of sensors may require specific calibration techniques, making it essential to choose one that fits your operational needs.

Regular calibration and validation against recognized standards will help maintain the integrity and reliability of your sensor data. It's advisable to look for sensors that align with industry benchmarks and standards, as this reflects their precision and credibility. Additionally, understanding the manufacturer's calibration processes and whether they provide documentation of accuracy can provide peace of mind in your selection. Choosing a sensor that is not only accurate but also adheres to established calibration standards can significantly enhance the reliability of your applications and ensure optimal performance.

Assessing Environmental Conditions and Sensor Durability

When selecting a tension sensor, understanding environmental conditions is crucial for ensuring optimal performance and longevity. The operating environment can significantly impact a sensor's functionality. For instance, exposure to extreme temperatures, humidity, dust, or chemicals can lead to premature failure or inaccurate readings. Thus, it is essential to choose a sensor that can withstand the specific conditions of your application, such as weatherproof sensors for outdoor use or corrosion-resistant materials for harsh industrial environments.

Moreover, sensor durability plays a pivotal role in minimizing maintenance costs and downtime. Selecting a sensor designed for rugged conditions, such as those equipped with protective housings or enhanced sealing, can enhance reliability in demanding applications. Additionally, evaluating the construction materials and design features helps ensure that the sensor not only operates effectively but also has a longer lifespan. By carefully assessing these factors, users can make informed decisions, ensuring that the tension sensor not only meets the immediate needs but also adapts to potential future challenges in the operating environment.

Integration and Compatibility with Existing Systems and Equipment

When selecting the right tension sensor for your applications, integration and compatibility with existing systems are paramount. Tension sensors must seamlessly fit into your current infrastructure without requiring extensive modifications or costly upgrades. This is essential not only for maintaining operational efficiency but also for minimizing downtime. For example, advanced CNC systems are designed to offer maximum performance while ensuring compatibility with previous generations, allowing for smooth transitions and consistent output. Similarly, when tension sensors can easily integrate with existing control systems, it reduces the learning curve for personnel and enhances overall productivity.

Moreover, considering the diverse range of equipment and sensors available, it's crucial to evaluate how potential new components will align with the current technology stack. This principle is evident in various sectors, from smart home devices that need to work harmoniously with ecosystems to industrial solutions where various machinery must communicate effectively. In a landscape that constantly evolves, choosing tension sensors that facilitate integration with your current systems not only enhances reliability but also paves the way for future technological advancements. Ensuring compatibility today sets the foundation for growth and innovation tomorrow.

Related Posts

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide

-

Solutions for Accurate Measurement with Micro Load Cells

-

Unleashing China's Manufacturing Excellence: A Deep Dive into the Best Torque Sensor Innovations

-

7 Unique Benefits of Compression Type Load Cells for Modern Industries

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs

-

Discovering the Best Compression Load Cells: A Global Buyer’s Guide for Performance and Reliability