sales@loadcellsensor.com

sales@loadcellsensor.com

Exploring Innovative Torque Sensor Types: Real-World Applications and Benefits

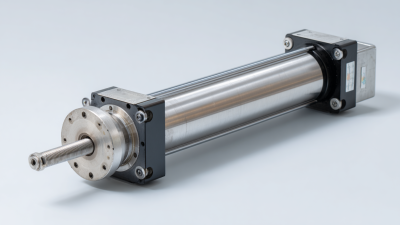

In the realm of modern engineering and technology, the demand for precision and reliability has led to the development of various Innovative Torque Sensor types. Torque sensors play a crucial role in measuring the rotational force applied to an object, providing essential data for a wide array of applications across diverse industries, from automotive to aerospace and manufacturing. This blog will delve into the different types of torque sensors available today, exploring their unique features, real-world applications, and the benefits they offer to enhance operational efficiency and safety.

Whether you are an engineer seeking to optimize machinery performance or a researcher exploring the latest advancements, understanding the functionality and versatility of torque sensors is key to navigating the challenges of modern engineering. Join us as we uncover how these innovative tools are revolutionizing industries and enabling a new era of precision engineering.

Understanding the Basics of Torque Sensors: Types and Functions

Torque sensors play a crucial role in various industries by measuring the rotational force applied to an object. These sensors can be categorized into several types, including strain gauge, piezoelectric, and magnetic torque sensors, each offering unique functionalities suited for different applications. According to a recent market report, the global torque sensor market is projected to grow at a CAGR of 5.3% from 2023 to 2030, highlighting the increasing demand for precision in automotive testing, aerospace, and industrial machinery.

One significant advantage of torque sensors is their ability to collect real-time data, which enhances the monitoring of mechanical systems. This capability proves invaluable in applications such as electric motor testing, where accurate torque measurements are essential for performance evaluation. In fact, a study indicates that implementing advanced torque measurement technology can improve operational efficiency by up to 15%.

Tip: When selecting a torque sensor, consider factors such as the sensor's range, accuracy, and environmental conditions. This ensures that the sensor can perform optimally under specific operational circumstances, thereby enhancing reliability and safety in your applications. Additionally, regular calibration and maintenance of torque sensors can significantly extend their lifespan and ensure consistent performance.

Exploring Innovative Torque Sensor Types: Real-World Applications and Benefits

| Sensor Type | Principle of Operation | Applications | Benefits |

|---|---|---|---|

| Strain Gauge Torque Sensors | Uses the deformation of a strain gauge to measure torque. | Automotive testing, robotics, industrial machinery. | High accuracy, compact size, wide range of applications. |

| Magnetoresistive Torque Sensors | Measures the change in resistance of magnetic materials under torque. | Robotics, aerospace, and automotive industries. | High reliability, maintenance-free, and excellent linearity. |

| Optical Torque Sensors | Utilizes light transmission changes to determine torque levels. | High-speed applications, automotive testing, precision engineering. | Non-contact measurement, high-speed response, immunity to electromagnetic interference. |

| Piezoelectric Torque Sensors | Generates an electrical charge proportional to applied torque. | Dynamic torque measurements in engines and machinery. | High sensitivity, suitable for dynamic applications. |

| Capacitive Torque Sensors | Uses changes in capacitance to measure torque. | Medical devices, robotics, and precision tools. | Compact design, easy integration into systems, good stability. |

Innovative Torque Sensor Technologies Impacting Various Industries

The evolution of torque sensor technologies is significantly reshaping industries by enhancing both operational efficiency and product quality. Innovative torque sensors offer solutions tailored to the specific demands of various sectors, from aerospace to automotive. These sensors enable precise measurement of rotational force in real-time, thereby facilitating advanced monitoring systems that inform machine performance and ensure optimal operation during complex machining processes. This capability is essential in high-precision environments where even minor deviations can lead to substantial quality issues.

Moreover, the integration of wireless torque sensors is a game-changer in the context of Industry 4.0. By eliminating the constraints of wired connections, these sensors provide greater flexibility and accessibility in data collection, allowing for seamless integration into smart production lines. This shift not only boosts productivity but also aids in predictive maintenance, as real-time data analytics can forecast potential issues before they escalate. As industries increasingly embrace these state-of-the-art technologies, the potential for enhanced operational effectiveness and elevated product quality continues to grow.

Real-World Applications of Torque Sensors in Automotive Engineering

In the realm of automotive engineering, torque sensors play a crucial role in enhancing vehicle performance and safety. These sensors are essential for monitoring the torque of various components, such as the engine and transmission systems, providing real-time data that enables precise control over vehicle dynamics. The application of torque sensors helps engineers identify performance bottlenecks, optimize power delivery, and refine the calibration of engine control units, leading to improvements in fuel efficiency and overall driving experience.

Moreover, torque sensors are integral in the development of advanced driver-assistance systems (ADAS) and electric vehicles (EVs). By ensuring accurate torque measurement, these sensors support features like torque vectoring, which enhances stability and traction by distributing power to individual wheels based on real-time road conditions. Additionally, in the context of EVs, torque sensors facilitate the efficient management of electric motors, ensuring that energy is used effectively, thereby extending range and optimizing regenerative braking systems. With such diverse applications, the significance of torque sensors in automotive engineering cannot be overstated, as they pave the way for innovative solutions that drive the industry forward.

Benefits of Using Advanced Torque Sensors in Industrial Automation

In the modern landscape of industrial automation, advanced torque sensors have emerged as indispensable tools for improving operational efficiency and ensuring product quality. These sensors, designed to measure and monitor torque in real-time, provide manufacturers with critical insights into the performance of machinery and tools. By integrating these sensors into automated systems, companies can achieve higher precision and reduce the likelihood of mechanical failures, which ultimately leads to lower maintenance costs and increased uptime.

One of the standout benefits of using advanced torque sensors is their ability to enhance process control. For instance, in applications involving assembly lines, precise torque measurements allow for optimal fastening processes, minimizing the risk of over-tightening or under-tightening components. This leads to improved product consistency and safety. Moreover, the data gathered from these sensors can also be leveraged for predictive maintenance, enabling facilities to anticipate equipment issues before they escalate into costly downtime. As industries continue to embrace automation, the role of torque sensors in enhancing reliability and efficiency becomes increasingly vital.

Future Trends in Torque Sensor Development and Their Potential Impact

The future of torque sensor technology is poised to reshape multiple industries, driven by the ongoing advancements in materials and smart technologies. According to a recent report by MarketsandMarkets, the torque sensor market is projected to grow from $0.72 billion in 2020 to $1.01 billion by 2025, at a compound annual growth rate (CAGR) of 7.3%. This growth is primarily attributed to the increasing demand for precision in monitoring and controlling mechanical systems in automotive, aerospace, and robotics applications.

One of the most exciting trends is the integration of IoT (Internet of Things) capabilities in torque sensors. As companies seek real-time data analytics for enhanced decision-making, torque sensors equipped with IoT functionalities can provide seamless communication between devices and cloud platforms. This enables predictive maintenance, minimizing downtime in critical operations. Furthermore, advancements in wireless technology are expected to facilitate easier installation and data transmission, leading to more widespread adoption in smart manufacturing environments. As industries continue to embrace digital transformation, torque sensors will play a vital role in optimizing performance and ensuring safety in machinery operations.

Related Posts

-

Maximizing Precision: Key Techniques for Effective Torque Sensor Implementation

-

Unleashing China's Manufacturing Excellence: A Deep Dive into the Best Torque Sensor Innovations

-

Precision Engineering: Chinese Manufacturing Innovating Global Torque Transducer Solutions

-

Navigating the Global Standards for Best Torque Sensor Imports and Exports

-

5 Compelling Reasons Why Torque Sensors Revolutionize Industrial Applications

-

10 Compelling Reasons to Choose Force Sensors for Your Next Project