info@loadcellsensor.com

info@loadcellsensor.com

-

Home

-

Products

-

News

-

About Us

-

Contact Us

Leave Your Message

-

CONTACT LCS TECH

CONTACT LCS TECH -

CONTACT LCS TECH

CONTACT LCS TECH

Up until this point in October 2023, one of the greatest difficulties is to ensure compliance with import regulations for companies that trade in specialized technologies such as Load Cells. The success of products in foreign market sectors rests on understanding the many aspects of international certifications, as these industries become more interlaced. For companies like LCS Tech Co., Ltd., which has been at the forefront of advanced strain gauge technology since 2012, it is therefore essential to navigate these requirements for growth while at the same time helping in the establishment of the reputation of "Made in China" quality.

LCS Tech Co. Ltd. is proud to supply high-performance load cells, force sensors, and torque transducers across more than 40 countries worldwide. It is vital that we now decode the tangled web of global import certification processes, as we continue showcasing the true nature of Chinese innovation. This guide will discuss relevant compliance requirements for Load Cells, further arming manufacturers, suppliers, and exporters with information that enables them to thrive in a competitive international market. Each of these certifications guarantees legality but also builds trust in our products and enhances their reputation amongst the international clientele.

In an interconnected world, load cell compliance is crucial in international trade. Load cells are part and parcel of industries, from manufacturing to food and beverage, where precise measurement is key. Ensuring compliance of load cells with international standards, therefore, gives credit to the product while helping avoid legal issues and costly penalties with importation. Load cells that are compliant with global import certifications show that they have been tested and verified to the required standards of safety and performance. This instills confidence in partners and consumers since such certification guarantees load cell reliable performance under expected conditions. Following these certification requirements will also enhance a company's standing in the marketplace, consequently offering an easy way to develop networks with suppliers and customers who care about quality and safety. While compliance might seem too cumbersome to comply with, understanding it is an indispensable thing for survival in the competitive world. Developing understanding on how different countries regulate load cells along the way will unlock further market opportunities. As businesses continue to expand their global footprints, focusing on load cell compliance becomes the key to their success.

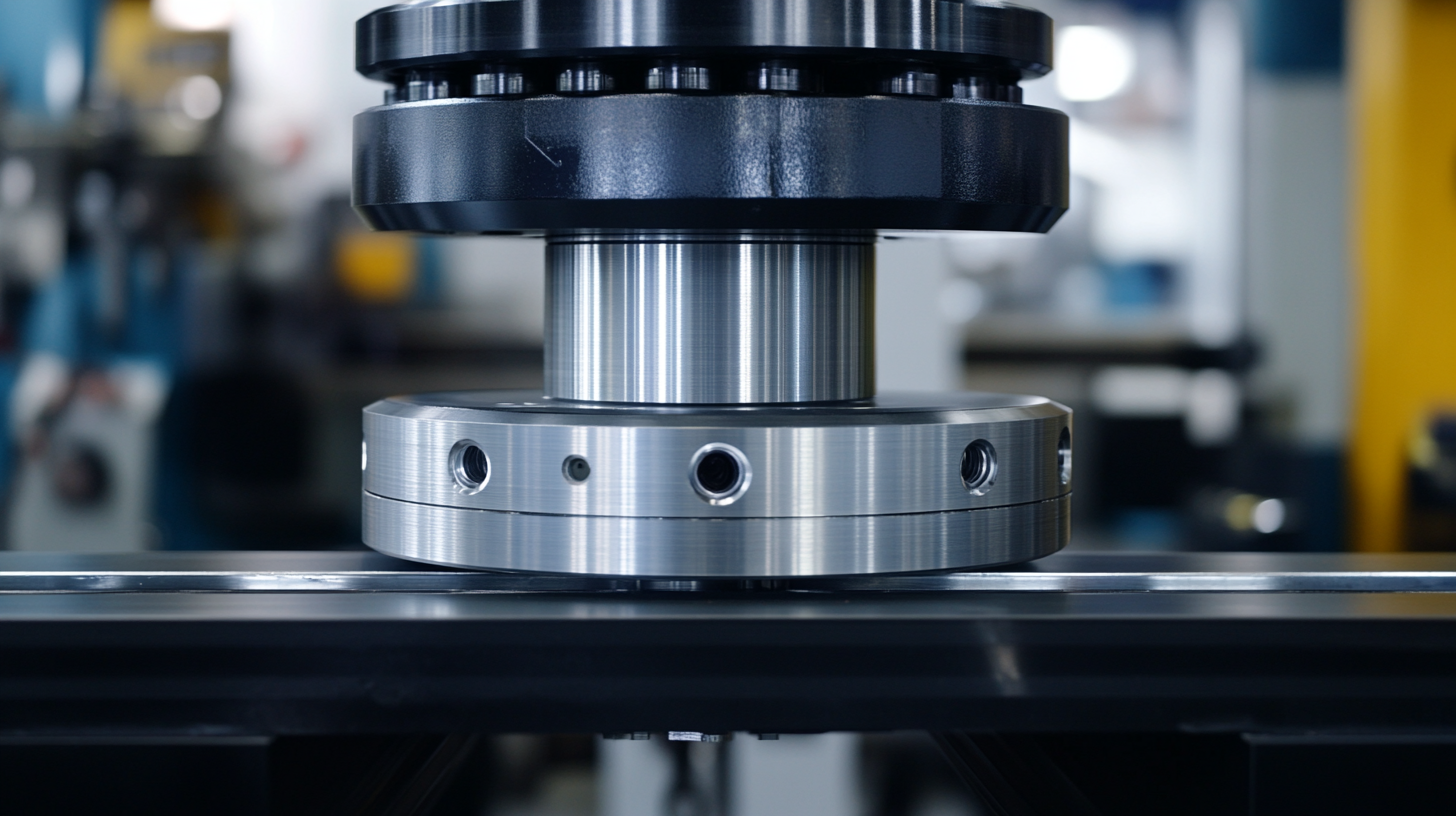

The juggling of global import certifications for load cells is very complicated for manufacturers and distributors in today's competitive landscape. The import processes for load cells are largely governed by major standards and regulations that ensure safety, reliability, and quality. The International Organization for Standardization (ISO) sets critical standards, obviously including ISO 376, dealing with the calibration of load measurement systems. An article from the International Society of Automation stated that conformity with ISO standards lends credibility to products and eases their cross-border entry.

Another regulation of primary importance in the import of load cells is the Conformité Européenne (CE) marking in the European Union, which demonstrates that the product fulfills basic health, safety, and environmental protection requirements. Load cells destined for the European market must comply with directives such as the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) requirements. A study conducted by the European Commission suggests that products conforming to CE marking stand a 30% greater chance of acceptance in EU markets, illustrating compliance importance for intercontinental trade.

Another regulation influencing load cell imports is in conformity with American National Standards Institute standards, which carry great importance for targeted Northern American market-load cell manufacturers. The ANSI standards consist of performance and calibration criteria providing the assurances for accuracy and reliability in load measurement applications that are ANSI/ASME B89.1.3. According to a survey by the National Institute of Standards and Technology, load cells complying with ANSI standards are indicated to vary up to 20% less in their measurements, thus strengthening the case for their need in load cells employed in industries. For companies to appreciate and work through the complexities concerning load-cell imports, understanding these international standards becomes vital.

The steps in keeping load cells safe and sure from being applicable in the world's market would include careful scrutiny of certification processes such as that of CE, UL, and ISO. Each type of certification is intended for a particular market and product and makes the difference between the quality of the product and the convenience of doing business across different borders.

CE market is the first mark for products that are to be sold in an Economic Area created in Europe because they declare that the latter complies with health, safety, and environmental protection standards. In fact, for the manufacturers, CE compliance would generally involve long, rigorous testing and documentation-an arduous process for many companies to understand the directives in their respective load cells, for ended fines or even a ban in the business-in this case, Europe.

On the other hand, UL certification is understood mostly as applicable in the United States and Canada; it certifies that a product has been tested for specific safety standards developed by Underwriters Laboratories. This serves those manufacturers eyeing North American markets, as having UL certification could foster further credibility and confidence amongst consumers on product use. Similar to CE, however, UL certification requires some complicated processes, such as understanding the safety standards applicable to load cells, which, again, may result in a design redesign.

Finally, ISO certification is a global endorsement of commitment to quality management. Although it is not a legal requirement, however, many customers and suppliers prefer or even demand products to have ISO certification to ensure that there are continuous processes of quality control. Hence, a company attaining such authority is likely to carry out international trade activities without hassle because trust will be increased in the reliability of a product's performance. Understanding all these certifications and what implications they might have may consequently make a huge difference in the journey to load cell compliance in the global market.

From the standpoint of load cell compliance, it bears testimony to regional differences in certification requirements that aid manufacturers and importers in the process. Each locality claims its prerogatives in laws, which in turn affects the design, manufacture, and testing of load cells. For instance, the European Union emanates stringent requirements under the Directive of Measuring Instruments (2014/32/EU) and requires EC certification and CE marking for load cells used in regulated applications. The United States places more emphasis on the guidelines of NIST with regard to traceability and accuracy in measurements.

Different regions may have unique standards on safety and environmental considerations. ISO standards are well-known internationally for many aspects of load cell performance, design, and testing. In the Asia-Pacific region, one may impose local adaptations of these standards, which will complicate compliance yet again. A paper issued by the International Organization of Legal Metrology has stated that compliance discrepancies increase the cost of doing business and cause delays, stressing the need for a complete understanding of and clear certification pathways.

Just as industries have begun to develop advanced technologies overnight-wearable devices for monitoring medical conditions like erectile dysfunction-the load cell industry is similarly benefiting from innovations that advance performance monitoring capabilities. Strong compliance frameworks means putting these technologies under examinations one can trust, along doing their necessary work across diverse applications in global markets. Newcomers in this area should keep their eyes on changes in compliance requirements so as to navigate the competitive field.

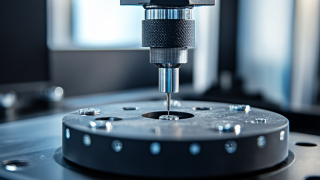

Verification and testing in load cell certification have been receiving very critical attention recently with the increasing demand for higher standards and compliance in global markets. A load cell, which is very important in several industrial applications, is put through a rigorous certification process in order to assure its accuracy and reliability. Verification denotes the set of systematic checks that these devices are meeting the required specifications, whereas testing assesses their performance against real-world scenarios. Such a process ensures regulation and compliance and thus guarantees safety and efficiency of the operations that this device more or less supports.

Contrapuntally, with rapid advancements in technology, especially in the automotive field, methodologies and equipment of the trade in load cell verification and testing are changing. Just as we've seen the advancement of sophisticated simulation software for autonomous vehicles, load cell testing is beginning to embrace these same technologies. These will provide for more precise simulation of load conditions, thereby increasing the reliability of results obtained during testing. Such interplay between advanced technology and stringent testing protocols will be vital for manufacturers who wish to keep pace with global standards and consumer expectations.

Also, with the increasing interconnectivity of markets today, the need to understand different certification requirements across the various regions becomes important. Each market segment may have compliance standards that allow designers and manufacturers of load cells to design differently, test differently, and verify differently. By understanding these requirements, manufacturers can ensure that their products are compliant and optimized for various design applications. Thus, verification and testing remain at the very center of ensuring successful load cell certification in an increasingly competitive international arena.

Variances from the global import certifications can diminish market access and inflate costs exponentially for companies, especially in those industries which are precision instrument-intensive, such as load cells. The World Bank recently published a report that stressed the necessity of a conducive business environment for trade facilitation and reducing barriers. In particular, firms concerned with fitness equipment exports in Ningjin County, Shandong, are faced with juggling national and global standards and regulations to satisfy compliance requirements. The existing requirement for certification places a heavy burden on the over 2,500 registered fitness equipment manufacturers in the region.

Non-conformance can have serious negative implications, such as further delaying their products in the foreign market, increasing inspection costs, and levying fines. For example, tightening up the regulations and audits may bring supply chains to a halt, and now manufacturers must act to train their staff and establish compliance systems. Companies that fall short of compliance would suffer not only exclusion from markets but also be denied access to that highly lucrative world today, which includes over 170 countries.

According to McKinsey, the dynamics of trade are changing, and more Chinese companies are eyeing Southeast Asia as a potential investment location with new markets emerging due to a growing middle class and developing economies. These markets also require knowledge of regulation on the local level with adherence to the international compliance standard. Therefore, compliance is for the manufacturers and exporters no longer an act of regulation; rather, it becomes a strategic necessity for achieving the success of today.

Manufacturers and importers of load cell technology must be on top of emerging trends in this highly dynamic environment. The major trend in load cell manufacturing is the growing digitization of load cells that not only improves the accurateness and performance but also facilitates real-time collection and analysis of data with capabilities of giving users real-time monitoring worldwide. With the growth of digital solutions, it becomes even more critical for load cells to comply with international standards and regulations to ensure these innovative instruments' safety and effectiveness.

The growing trend is environmental sustainability concerning the load cell scope. Manufacturers are focusing on developing products that are less Eco-unfriendly with sustainable materials and energy-efficient processes. This trend complements consumers' desires for greener products and supports the international laws that encourage environmental technologies. Adherence to these sustainability principles is vital in getting import certification because the subject of eco-friendliness becomes a priority as far as regulatory authorities across the globe are concerned with their compliance framework.

A rising advance in the industry is the technology involving wireless load cell systems and the past wired systems. Wireless systems provide flexibility and convenience for installation at problem locations. As the wireless technology continues to develop, standards for compliance are changing too for those solutions. Adapting to the combined intricacies of wireless load cell compliance will require the industry to be on the edge of all developing standards and best practices, ensuring that products are keeping up with the rigid requirements set by global markets.

Success in certification of load cells should be ensured and secured for manufacturers and distributors who want to venture into the complex maze of global import certifications. Understanding what the specific regulatory requirements are, in every intended market, is the foremost requirement. Each country's load cells are characterized by safety, performance, and environmental concerns, which are different from one another. Researching the requirements would greatly help a company align its product to international standards, which leads to simple certification.

Also, working with accredited laboratories for testing is a milestone in getting a load cell certified. Apart from their knowledge in solving compliance issues, testing laboratories will also be able to shed light on the things that the manufacturer might encounter and improve on. Establishing a proactive relationship with those laboratories will pave the way for less troublesome testing phases, which eventually lead to quicker certification. Lastly, manufacturers would do well also to seek the services of consultants known for their expertise in load cell compliance, so that more than one person's perception can be from the same and more likely effective approach.

Besides, documentation is either really important or critical for this certification process. Design and testing specifications and compliance reports save you much when it comes to such evaluations. The use of a good system of structure documentation allows fast responses to any questions raised by regulatory bodies. By focusing on these good practices - understanding regulatory requirements, engaging with testing labs, and comprehensive documentation - companies will also navigate the complexity of load cell certification, as this would, in the end, tend to prepare the company for international market entry and growth.

A significant trend is the increasing integration of digital technologies in load cells, which enhances accuracy and enables real-time data collection and monitoring.

Manufacturers are focusing on creating load cells that minimize ecological impact through sustainable materials and energy-efficient processes to meet consumer demand and align with global regulations.

Compliance is critical to ensure that load cells remain safe and effective, especially as digital and wireless technologies become more prevalent in the industry.

The industry is seeing advancements that offer more flexibility and ease of installation, particularly in challenging environments compared to traditional wired systems.

Manufacturers need to understand the specific regulatory requirements of their target markets, as different countries have varying standards for load cells.

Collaboration with these laboratories provides technical expertise and insights into potential pitfalls, facilitating smoother testing phases and faster certification timelines.

Maintaining comprehensive documentation of design specifications, testing results, and compliance reports is essential for responding to regulatory queries and streamlining the evaluation process.

Engaging with compliance specialists ensures that manufacturers adopt consistent and effective approaches to meet regulatory requirements for their products.

The best practices include understanding regulatory requirements, collaborating with testing labs, and implementing a structured documentation system.

Adapting to sustainability guidelines is essential for gaining import certifications, as regulatory bodies prioritize eco-conscious products in their compliance frameworks.