sales@loadcellsensor.com

sales@loadcellsensor.com

The Ultimate Guide to Sourcing High-Quality Suppliers for Best Button Type Load Cells

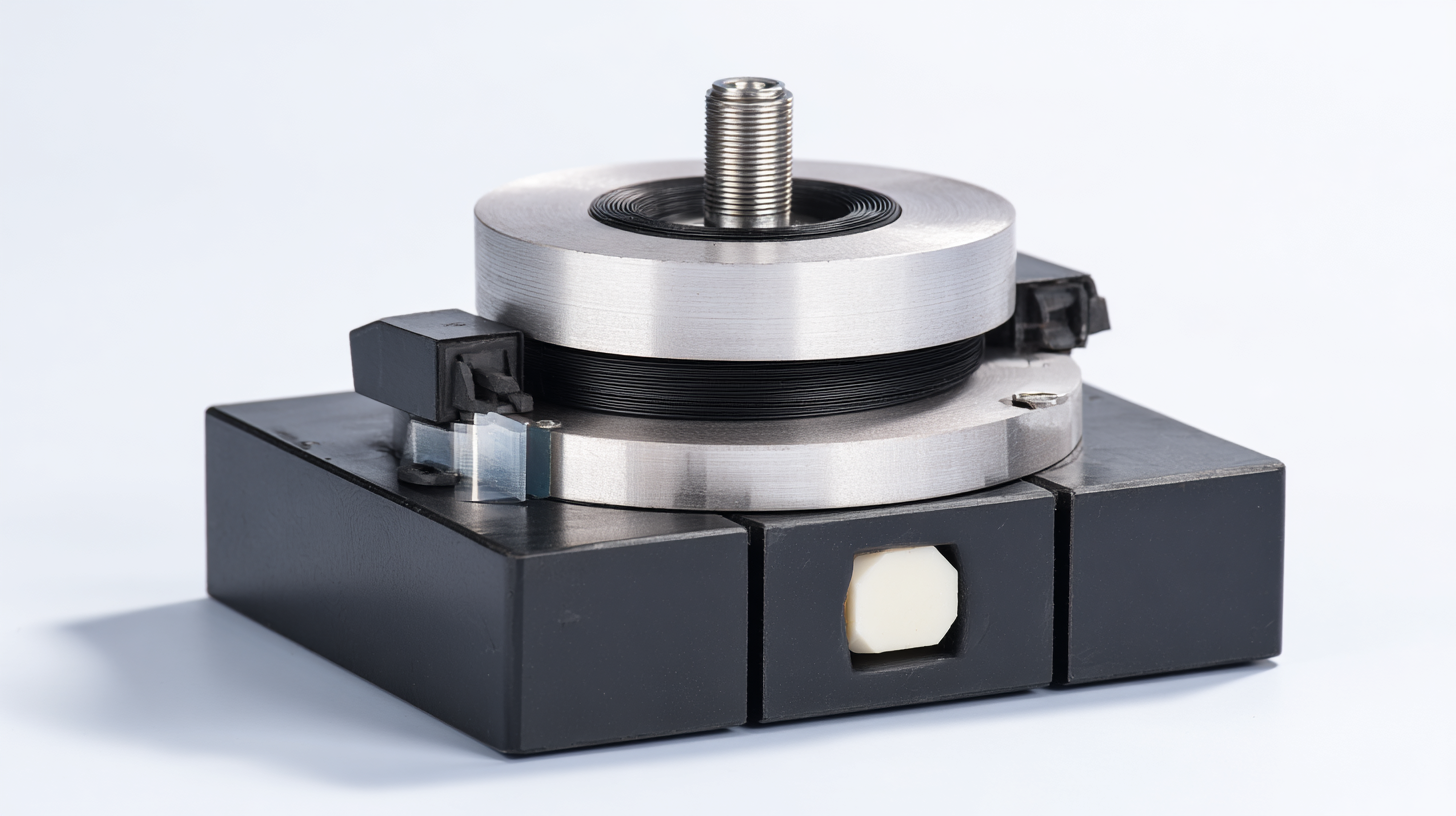

In the realm of precision measurement, Button Type Load Cells have emerged as a vital component for various industrial applications, ranging from weighing systems to force measurement devices. According to a recent market analysis by the International Society of Automation, the global load cell market is projected to reach USD 1.2 billion by 2027, with a significant share attributed to Button Type Load Cells due to their compact design and high accuracy. However, sourcing high-quality suppliers for these specialized components can be a daunting task, as the market is saturated with options varying in quality and reliability. This guide aims to provide valuable insights and practical strategies for identifying and securing the best suppliers, ensuring that your Button Type Load Cell needs are met with top-tier products that adhere to industry standards and performance benchmarks.

Strategies for Identifying Reliable Suppliers for Load Cells in 2025

In 2025, identifying reliable suppliers for load cells has become increasingly crucial, particularly with the rising demand for precision in industrial applications such as silo weighing. A pivotal example of this trend is the newly released mounting kit that simplifies silo weighing processes, boasting features like rapid installation and high accuracy, which are essential for efficient operations. According to industry reports, the global load cell market is expected to reach approximately $1.86 billion by 2026, growing at a CAGR of 5.5%. This growth underscores the pressing need for businesses to source high-quality suppliers capable of meeting these evolving technological demands.

When sourcing for load cells, companies should leverage a combination of online resources and trade shows to evaluate potential suppliers. Attending events like Anuga FoodTec 2025 allows businesses to engage directly with manufacturers, assess their innovations, and gain insights into their quality assurance processes. Additionally, looking into suppliers' certifications and client testimonials can provide further validation of their reliability. Ultimately, the ability to identify and partner with trustworthy suppliers will be a significant factor in maintaining a competitive edge in an increasingly intricate marketplace.

Key Quality Indicators to Evaluate Button Type Load Cell Manufacturers

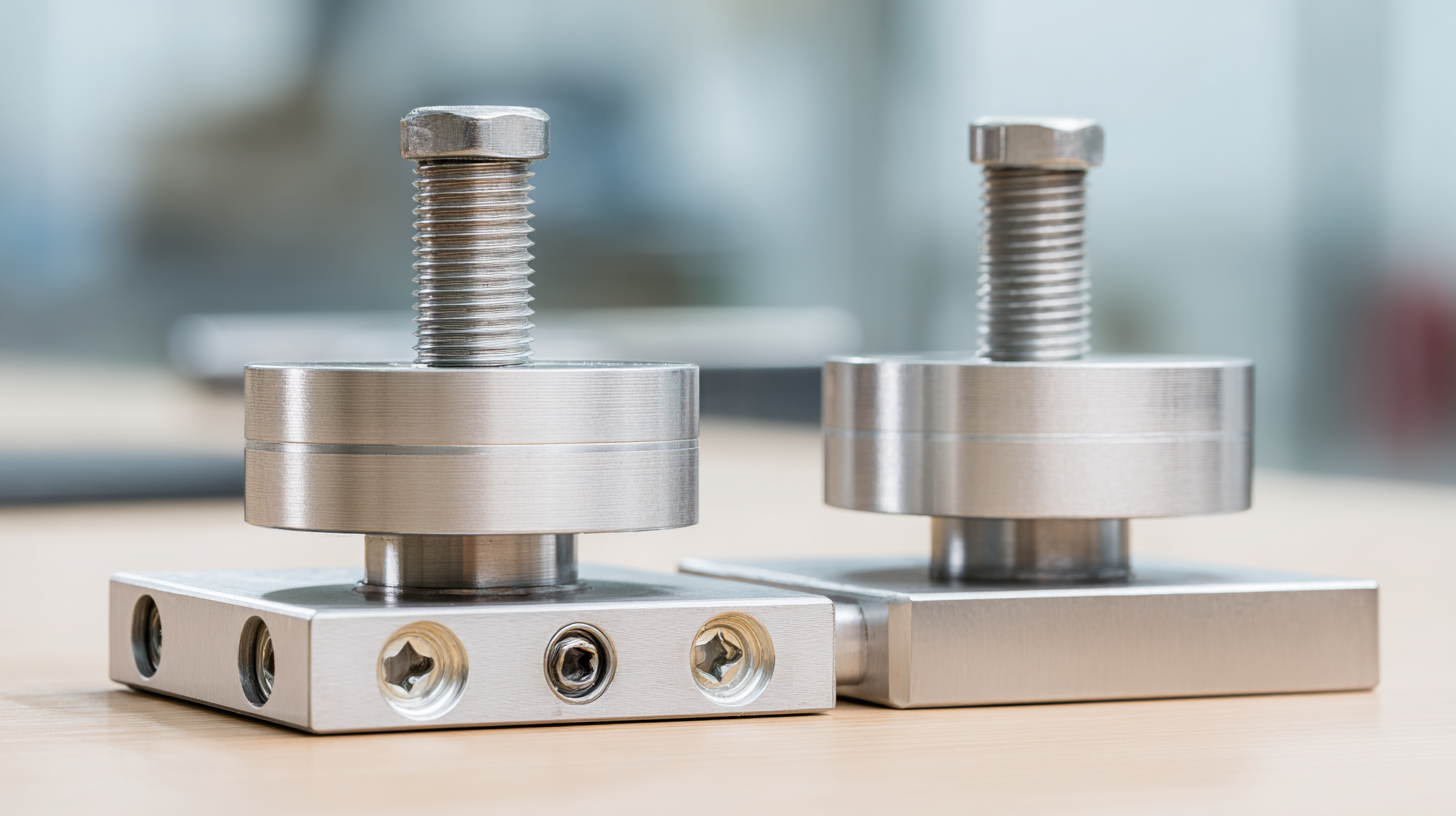

When sourcing high-quality suppliers for button type load cells, it is essential to evaluate manufacturers through a set of key quality indicators. First and foremost, consider the manufacturer's certifications and compliance with international standards, such as ISO 9001. These certifications ensure that the supplier adheres to consistent quality management processes. Additionally, investigate their experience in the industry, as established manufacturers tend to have a proven track record in producing reliable and durable load cells.

Another important indicator is the manufacturer's testing and quality control processes. High-quality button type load cell suppliers typically implement rigorous testing protocols to ensure their products meet specific performance criteria. Look for manufacturers that provide detailed information about their testing methods, including calibration tests and reliability evaluations. Furthermore, customer reviews and testimonials can offer valuable insights into the consistency of product quality and the manufacturer's responsiveness to issues, ultimately aiding in your selection of the best supplier.

The Ultimate Guide to Sourcing High-Quality Suppliers for Best Button Type Load Cells - Key Quality Indicators to Evaluate Button Type Load Cell Manufacturers

| Supplier Region | Quality Certification | Average Lead Time (Weeks) | Customer Satisfaction Rating (Out of 5) | Minimum Order Quantity |

|---|---|---|---|---|

| North America | ISO 9001 | 4 | 4.7 | 100 units |

| Europe | CE, ISO 9001 | 5 | 4.5 | 50 units |

| Asia | ISO 9001, RoHS | 6 | 4.0 | 200 units |

| South America | ISO 9001 | 5 | 4.2 | 150 units |

| Africa | ISO 9001 | 7 | 3.8 | 250 units |

Emerging Trends in Load Cell Technology and Their Impact on Supplier Selection

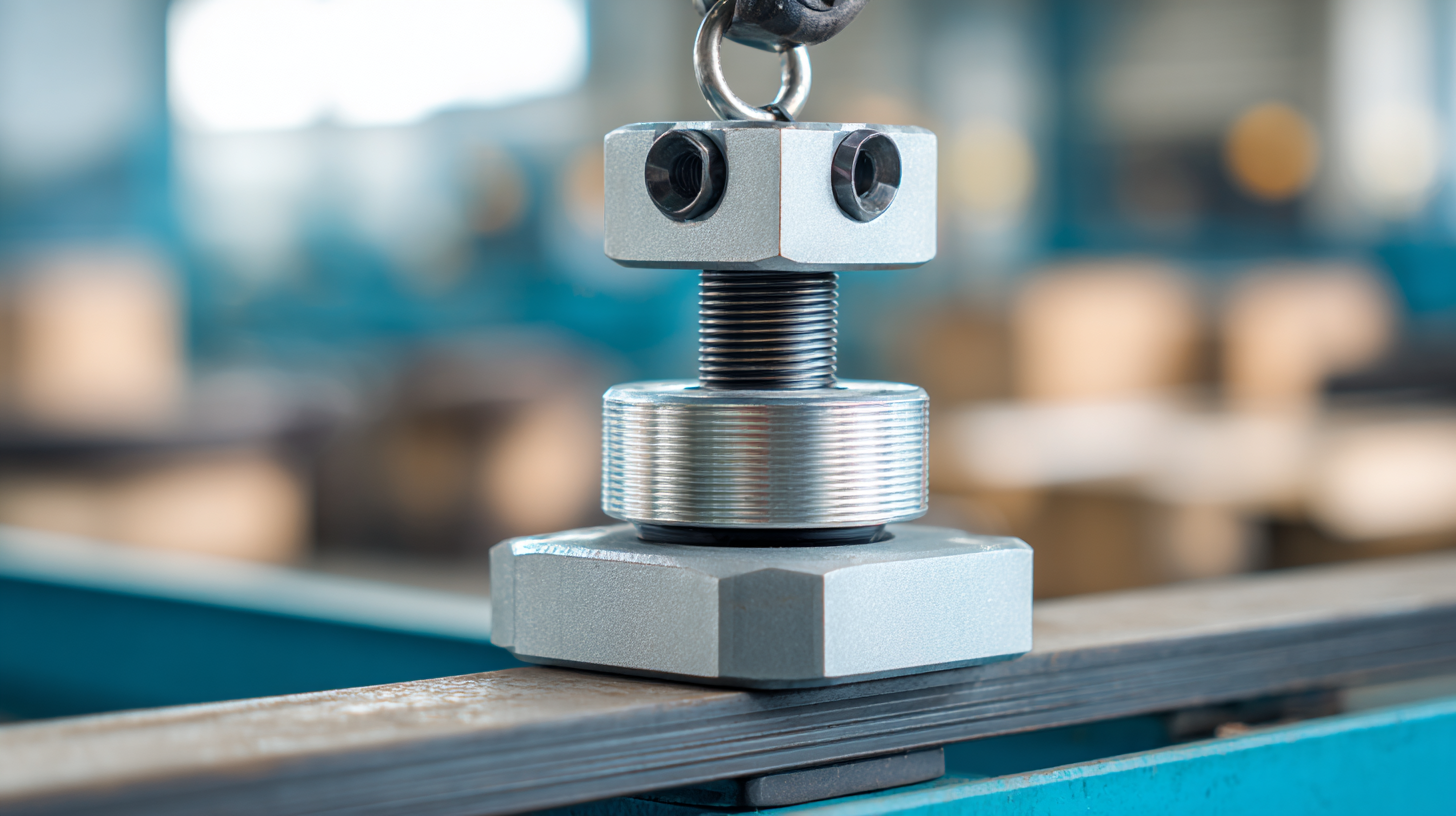

In the ever-evolving landscape of load cell technology, staying abreast of emerging trends is crucial for businesses seeking to source high-quality suppliers. One significant development is the integration of IoT capabilities into load cells, allowing for real-time data collection and remote monitoring. This innovation enhances operational efficiency and provides better insights into performance metrics, thereby influencing supplier selection. Companies must prioritize suppliers who offer advanced IOT-enabled load cells to stay competitive in the market.

Another essential trend is the increasing focus on sustainability and eco-friendly manufacturing practices. As environmental concerns grow, suppliers that adhere to stringent sustainability standards will likely become more desirable. Businesses should assess potential suppliers not only on the quality of their load cells but also on their commitment to environmentally responsible practices. By aligning supplier selections with these emerging trends, companies can ensure they are equipped with the latest technology while also contributing positively to global sustainability efforts.

Building Strong Relationships with Suppliers: Best Practices for the Load Cell Industry

Building strong relationships with suppliers is pivotal for businesses in the load cell industry, especially given the rising demand for quality components as new technologies emerge. According to recent industry reports, the market for load cells is projected to grow at a CAGR of 4.9% through 2027, driven by advancements in automation and smart manufacturing solutions. This growth underscores the importance of partnering with high-quality suppliers who can ensure reliable performance and durability in their products.

In a rapidly evolving supply chain landscape, effective supplier relationship management can provide a competitive edge. Best practices include transparent communication and collaboration, which not only improve operational efficiency but also enhance innovation. Companies should consider implementing strategic partnerships, much like those seen in the electric vehicle sector, where battery manufacturers are rethinking procurement and logistics to meet soaring demand. As such, load cell manufacturers can adopt similar strategies to foster resilience and agility in their supply chains, ensuring they are well-prepared to meet the demands of an increasingly automated future.

Navigating Supply Chain Challenges: Ensuring Consistent Quality in 2025

In 2025, navigating the complexities of supply chain challenges is paramount for businesses reliant on high-quality button type load cells. The global market is increasingly interconnected, making it essential for companies to cultivate robust relationships with suppliers who can consistently meet stringent quality standards. To achieve this, organizations must prioritize transparency and communication throughout the supply chain. Open channels allow for timely feedback and adjustments, ensuring that any potential quality issues can be addressed promptly.

Additionally, investing in technology plays a critical role in maintaining quality assurance. Implementing advanced monitoring systems and data analytics can provide real-time insights into supplier performance and product integrity. This proactive approach not only enhances decision-making but also builds stronger partnerships with suppliers, established on trust and reliability. By embracing these strategies in 2025, companies can effectively mitigate supply chain risks and secure a steady flow of high-quality materials crucial for their operations.