sales@loadcellsensor.com

sales@loadcellsensor.com

How to Choose the Best Low Profile Load Cell for Your Application

When it comes to precision measurement in various industrial applications, selecting the right equipment is paramount, and the Low Profile Load Cell stands out as an ideal choice for many scenarios. These compact devices not only save space but also provide accurate weight measurements, making them essential for applications ranging from material testing to automated systems.

However, with a wide array of options available on the market, choosing the best Low Profile Load Cell for your specific needs can be a daunting task. Factors like capacity, accuracy, and environmental conditions play a crucial role in ensuring that you make an informed decision. In this blog post, we will guide you through essential considerations and tips for selecting the most suitable Low Profile Load Cell, helping you enhance the efficiency and reliability of your applications.

However, with a wide array of options available on the market, choosing the best Low Profile Load Cell for your specific needs can be a daunting task. Factors like capacity, accuracy, and environmental conditions play a crucial role in ensuring that you make an informed decision. In this blog post, we will guide you through essential considerations and tips for selecting the most suitable Low Profile Load Cell, helping you enhance the efficiency and reliability of your applications.

Understanding Load Cell Basics: Types and Principles of Operation

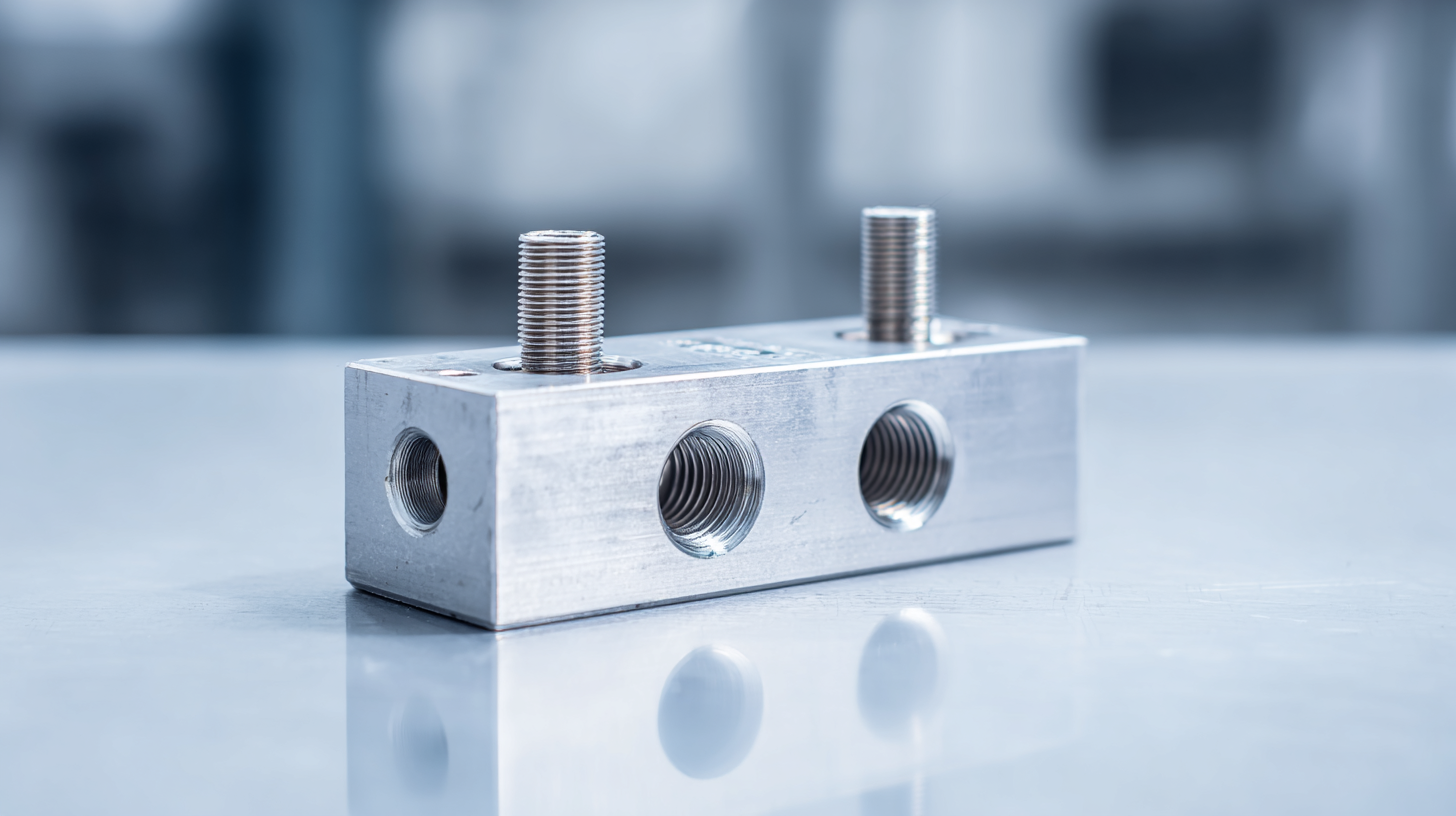

Understanding load cell basics is crucial when selecting the best low profile load cell for your application. Load cells are devices that convert force or weight into an electrical signal, commonly used in weighing scales and industrial applications. There are several types of load cells, including compression, tension, and bending beam, each designed for specific loading conditions. According to a recent market analysis by Research and Markets, the global load cell market is expected to grow at a CAGR of over 6% from 2021 to 2026, driven by advancements in sensor technology and increased automation in manufacturing.

When choosing a load cell, consider the principle of operation. Strain gauge load cells are the most widely used due to their accuracy and reliability, representing over 70% of the market share. For applications requiring lower profiles, many manufacturers now offer miniaturized load cells that maintain these performance standards while fitting within confined space constraints.

Tip: Always match the load cell’s capacity with your application’s requirements to avoid overloading, which can lead to damage. Additionally, environmental considerations such as temperature and humidity can affect performance, so consult the specifications thoroughly before making a decision. By understanding these fundamentals, you can ensure optimal performance and longevity of your load cell in various applications.

Key Specifications That Impact Load Cell Performance

When selecting a low profile load cell for your application, understanding key specifications that impact performance is crucial. One of the primary factors to consider is the load cell's accuracy and sensitivity. These metrics define how well the load cell can measure the applied force, and even a slight deviation can lead to significant errors in high-precision applications. For optimal performance, look for load cells with a high resolution and minimal hysteresis.

Tip: Always check the manufacturer's specifications to ensure the load cell meets your accuracy requirements for your specific application. This can prevent unwanted discrepancies in your measurements.

Another important specification is the environmental ratings, particularly if your application involves exposure to dust, moisture, or chemicals. Low profile load cells are available with various sealing options, and choosing one with the appropriate ingress protection (IP) rating can enhance durability and performance.

Tip: Consider your application’s environment carefully. For instance, if you're operating in a wet area, opt for a load cell that has a high IP rating to ensure longevity and reliability in adverse conditions.

Load Cell Performance Comparison

This chart compares the key specifications of three different low profile load cells. Each specification impacts their performance and suitability for various applications.

Factors to Consider for Low Profile Load Cells in Specific Applications

When selecting the best low profile load cell for your specific application, several key factors come into play. One of the primary considerations is the capacity of the load cell. According to recent studies, advancements in load cell technologies have enabled significant improvements in performance, particularly in terms of accuracy and resolution. For instance, modern low profile load cells can achieve measurement accuracies of up to 0.01%, making them suitable for applications ranging from industrial weighing to medical equipment.

Another crucial factor to consider is environmental compatibility. As industries move towards sustainable practices, the materials used in load cells are being scrutinized. Recent assessments indicate that the integration of sustainable building materials and innovative production technologies is influencing the development of load cells that are not only efficient but also environmentally friendly. This shift not only enhances performance but also positions companies favorably in the market where eco-conscious practices are becoming paramount. Hence, choosing a load cell that balances performance with sustainability is essential for long-term application success.

Evaluating Accuracy and Sensitivity in Low Profile Load Cells

When selecting a low profile load cell for your specific application, understanding the nuances of accuracy and sensitivity is paramount.

Accuracy refers to how close a load cell's measurements are to the true value, while sensitivity denotes the amount of change in output for a given change in input.

In essence, a sensitive load cell will respond more robustly to minor weight changes, making it ideal for applications requiring precise measurements, such as in laboratory settings or quality control processes.

Recent advancements in measurement technologies, paralleling developments in areas like metagenomic analysis and molecular diagnostics, highlight the importance of both accuracy and sensitivity.

For instance, new methods in bacterial strain quantification and droplet digital PCR illustrate how enhanced sensitivity can dramatically improve results.

Similarly, when choosing a low profile load cell, you should assess its performance metrics, including both statistical accuracy and sensitivity ratings.

This ensures that you are not only obtaining reliable measurements but also capturing subtle changes that could be critical to your application’s success.

Investing in a high-quality load cell with proven performance characteristics will ultimately yield better data integrity and operational efficiency.

Comparative Analysis: Costs vs. Benefits of Popular Low Profile Load Cells

When selecting a low profile load cell, understanding the balance between costs and benefits is crucial for optimal performance in your application. Popular models vary significantly in price, but this doesn't always reflect their utility. For instance, while some budget-friendly load cells may save initial investment costs, they can compromise on accuracy and durability. Conversely, higher-priced options often incorporate superior technologies that enhance their reliability and precision, making them a worthwhile investment for long-term use.

Comparative analysis reveals that the most well-regarded low profile load cells, despite their higher upfront costs, frequently provide enhanced features such as better temperature compensation and lower hysteresis. These benefits reduce operational errors and increase the longevity of the equipment, translating to cost savings in maintenance and replacements. Ultimately, weighing these costs against the potential benefits helps ensure that your choice aligns with both your budget and the specific demands of your application.

Related Posts

-

Exploring Alternative Load Cell Solutions for Optimizing Tensile and Compressive Testing

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide

-

Top 10 Pancake Load Cell Manufacturers from China at the 137th Canton Fair

-

Top Strategies for Selecting the Best 5kg Load Cell for Your Business Needs

-

Ensuring Excellence: Global Industry Standards for the Best Single Point Load Cells

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs