sales@loadcellsensor.com

sales@loadcellsensor.com

Understanding Inline Load Cells: Revolutionizing Weight Measurement in Modern Industries

In the rapidly evolving landscape of modern industries, accurate weight measurement stands as a cornerstone for operational efficiency and quality control. The Inline Load Cell has emerged as a game-changing technology, enabling real-time weight monitoring directly within production processes. According to a recent market report by Grand View Research, the global load cell market is projected to reach USD 4.64 billion by 2025, underscoring the growing demand for precise and reliable weight measurement solutions.

As industries such as manufacturing, pharmaceuticals, and logistics increasingly embrace automation, Inline Load Cells provide not only improved accuracy but also significant enhancements in speed and integration capabilities. This innovative approach is poised to revolutionize how businesses manage weight metrics, offering a robust solution to meet the escalating demands of quality assurance and regulatory compliance in various sectors.

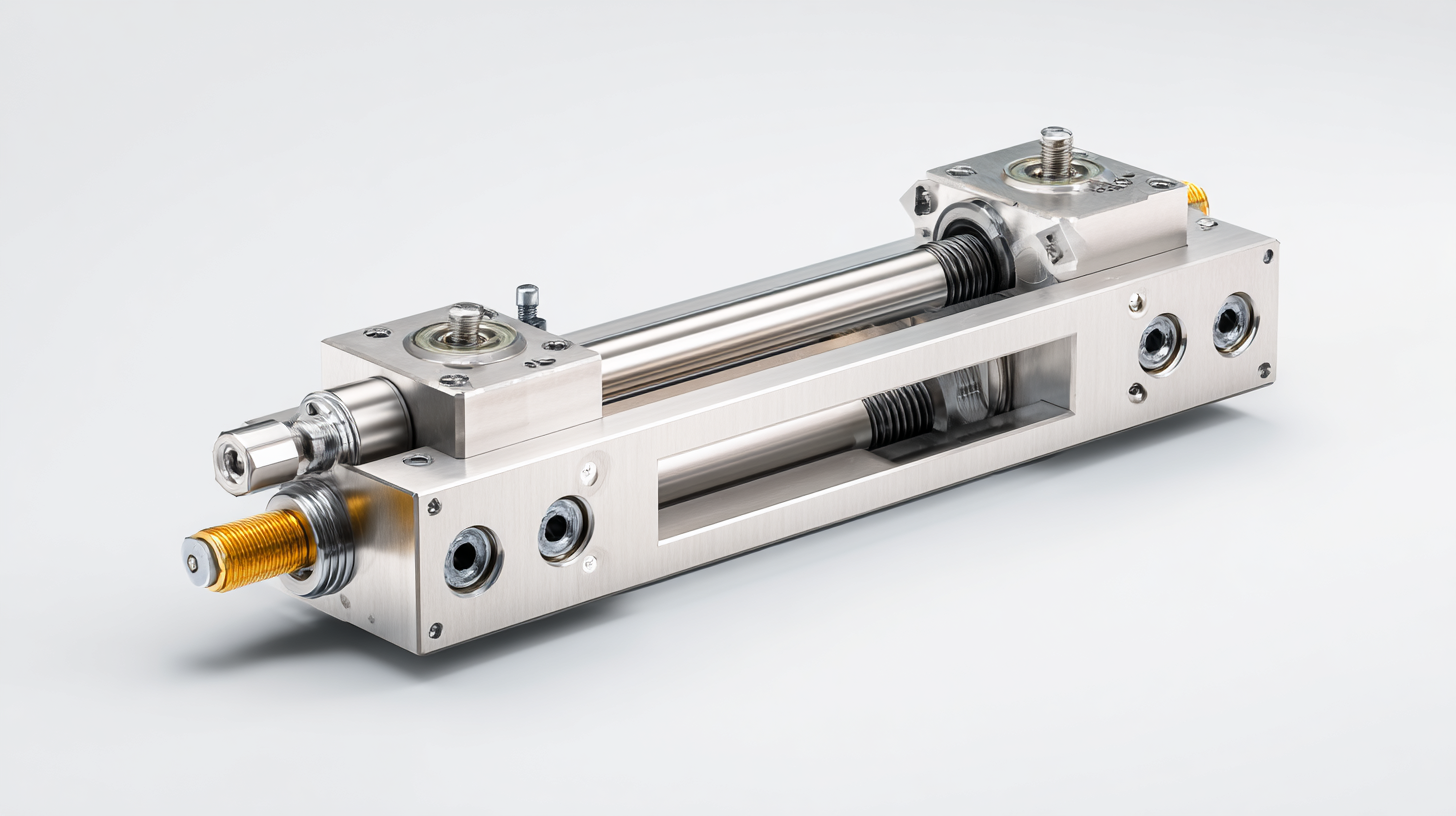

The Principles of Inline Load Cells and Their Operational Mechanisms

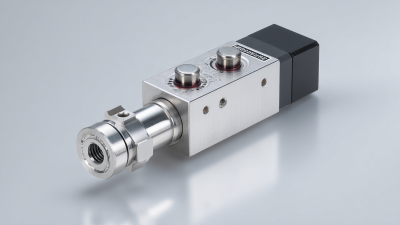

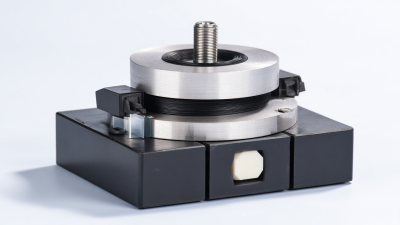

Inline load cells are transforming the weight measurement landscape across various industries, leveraging advanced operational mechanisms to enhance precision and efficiency. These sensors operate based on strain gauge technology, where the deformation of the material translates into an electrical signal proportional to the weight applied. This mechanism allows for real-time monitoring and data collection, which is crucial in applications ranging from manufacturing to logistics.

Recent insights highlight that effective monitoring systems, including inline load cells, significantly mitigate risks associated with material degradation such as corrosion or wear. For instance, studies indicate that monitoring tools can detect installation damages and manufacturing flaws early on, thus ensuring optimal mooring integrity and performance over time. The ability to measure weight and load dynamically also contributes to improved management of dense suspensions in various processes, directly addressing high shear rate applications in industries like polymers and food processing.

Recent insights highlight that effective monitoring systems, including inline load cells, significantly mitigate risks associated with material degradation such as corrosion or wear. For instance, studies indicate that monitoring tools can detect installation damages and manufacturing flaws early on, thus ensuring optimal mooring integrity and performance over time. The ability to measure weight and load dynamically also contributes to improved management of dense suspensions in various processes, directly addressing high shear rate applications in industries like polymers and food processing.

Tips: When implementing inline load cells, ensure calibration is performed regularly to maintain accuracy. Additionally, consider the environmental conditions, as temperature and humidity can affect sensor performance. Lastly, always opt for high-quality materials to minimize the risk of fatigue and enhance sensor longevity.

Key Benefits of Inline Load Cells for Real-Time Weight Measurement

Inline load cells are transforming weight measurement across various modern industries by offering real-time capabilities that significantly enhance operational efficiency. According to a recent report by MarketsandMarkets, the global load cells market is projected to reach $1.5 billion by 2026, driven by the increasing demand for automation and precise monitoring in manufacturing, logistics, and food processing sectors. This growth underscores the critical role of inline load cells in ensuring accurate weight measurement during production processes, thereby minimizing errors and waste.

One of the key benefits of inline load cells is their ability to provide continuous weight data, facilitating immediate adjustments in manufacturing lines. For instance, the Food and Agriculture Organization (FAO) notes that accurate weight measurement can reduce packaging errors by up to 30%, thereby increasing profitability. Inline load cells enable businesses to monitor weight variations in real-time, allowing for swift interventions that enhance productivity and reduce material costs. Additionally, their integration into automated systems leads to a reduction in labor costs and lower operational risks, making inline load cells an essential component for industries aiming to improve their efficiency and accuracy in weight measurement.

Industry Applications: How Inline Load Cells Enhance Production Efficiency

Inline load cells have emerged as a transformative technology in various industries, enhancing production efficiency through precise weight measurements. In the manufacturing sector, for example, the global market for load cells is projected to grow at a CAGR of 6.5%, reaching approximately $8 billion by 2027, according to a report by MarketsandMarkets. This growth underscores the integral role of inline load cells in automating processes, reducing errors, and ensuring consistent product quality. Their ability to provide real-time feedback on weight measurements allows industries to optimize operations and minimize waste, leading to significant cost savings.

In sectors such as food and beverage, pharmaceuticals, and logistics, the implementation of inline load cells has demonstrated substantial advancements. A study by the International Society of Automation indicates that integrating inline load cells in production lines can improve measurement accuracy by up to 0.1%, resulting in better compliance with regulatory standards and enhanced product integrity. Furthermore, in automated packaging solutions, inline load cells facilitate precise dosage control, ensuring that packaging is neither over nor underfilled, which is crucial for maintaining customer satisfaction and reducing product loss. These innovations illustrate how inline load cells are essential for streamlining processes and boosting operational efficiency across modern industries.

Understanding Inline Load Cells: Revolutionizing Weight Measurement in Modern Industries - Industry Applications: How Inline Load Cells Enhance Production Efficiency

| Industry | Application | Benefits | Improvement in Efficiency (%) |

|---|---|---|---|

| Manufacturing | Automated Material Handling | Reduced waste and enhanced accuracy | 20% |

| Food Processing | Ingredient Weighing | Consistency in product quality | 15% |

| Pharmaceuticals | Batch Weighing | Regulatory compliance and accuracy | 25% |

| Logistics | Load Monitoring | Improved load validation and safety | 30% |

| Construction | Material Weight Distribution | Enhanced structural integrity | 22% |

Comparison of Inline Load Cells with Traditional Weighing Methods

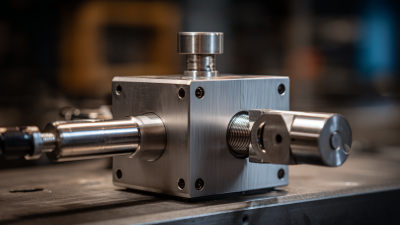

Inline load cells represent a significant advancement over traditional weighing methods, particularly in terms of precision, integration, and efficiency in various industries. Traditional weighing methods often involve the use of mechanical scales or balances, which can be bulky and less accurate under dynamic conditions. In contrast, inline load cells offer seamless integration into production lines, allowing for real-time weight measurement without interrupting the workflow. This technology is particularly beneficial in industries like food processing and pharmaceuticals, where precision is crucial for quality control and compliance.

According to industry reports, inline load cells can improve measurement accuracy by up to 0.01% compared to traditional methods, significantly reducing the risk of product loss due to over or underweight conditions. This level of precision is essential in maintaining operational efficiency and meeting regulatory standards. Additionally, inline load cells often feature advanced sensors that can monitor weight continuously, providing data that aids in predictive maintenance and optimization of manufacturing processes.

**Tips:** When considering the transition to inline load cells, it's vital to assess your specific operational needs and integration capabilities. Investing in high-quality load cells can provide long-term savings by enhancing productivity and reducing waste. Regular maintenance and calibration are also crucial to ensure continued accuracy and performance in your application.

Future Trends in Inline Load Cell Technology and Industry Adoption Rates

Inline load cells are transforming weight measurement across various industries, with a notable increase in their adoption rates. According to a recent report by MarketsandMarkets, the global load cell market, which includes inline models, is projected to reach USD 5.47 billion by 2026, growing at a CAGR of 5.4% from 2021. The push for automation and precision in sectors such as food and beverage, pharmaceuticals, and logistics is driving this surge, as inline load cells provide real-time data and enhanced reliability in weight measurement processes.

Future trends indicate an ongoing shift towards digital and smart technologies within inline load cells. A study by Grand View Research highlights that the integration of IoT capabilities into load cells is expected to create a more streamlined and connected measurement system, with the smart load cell segment anticipated to grow significantly. Furthermore, industries are increasingly recognizing the importance of data analytics, which enhances operational efficiency and reduces waste. As inline load cell technology evolves, we can expect broader adoption and innovation, reshaping traditional weight measurement practices and elevating industry standards.

Related Posts

-

Top 10 Micro Load Cell Manufacturers from China at the 137th Canton Fair

-

Exploring Innovative Alternatives to the Best Tension Compression Load Cell for Global Buyers

-

Solutions for Accurate Measurement with Micro Load Cells

-

Advantages of Utilizing Ring Load Cells for Precise Industrial Measurements

-

How to Maximize Efficiency in Your Operations with Bending Beam Load Cells

-

The Ultimate Guide to Sourcing High-Quality Suppliers for Best Button Type Load Cells