sales@loadcellsensor.com

sales@loadcellsensor.com

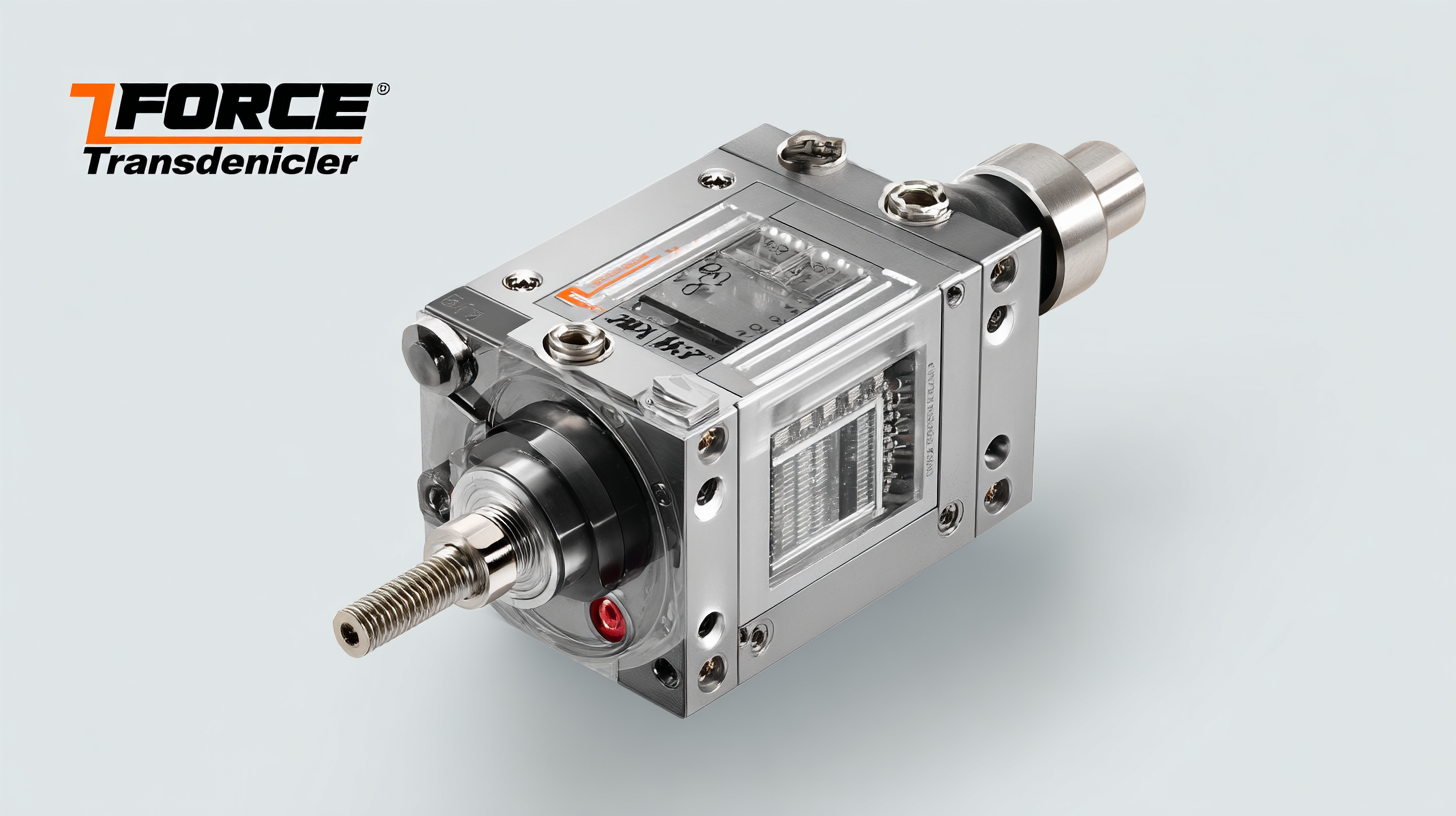

5 Key Advantages of Choosing the Best Force Transducer for Your Applications

In the rapidly evolving landscape of industrial applications, the significance of precision and reliability cannot be overstated. According to a report by MarketsandMarkets, the global force transducer market is expected to reach $1.2 billion by 2025, growing at a CAGR of 7.5%. This surge emphasizes the critical role of force transducers in various sectors, including automotive, aerospace, and manufacturing, where accurate force measurements are paramount for quality assurance and operational efficiency.

Choosing the best force transducer tailored to your specific applications not only enhances measurement accuracy but also contributes to improved process control and safety. As industries increasingly prioritize technological advancements and enhanced product performance, understanding the key advantages of these instruments becomes essential for engineers and decision-makers alike.

Top Applications of Force Transducers Across Various Industries

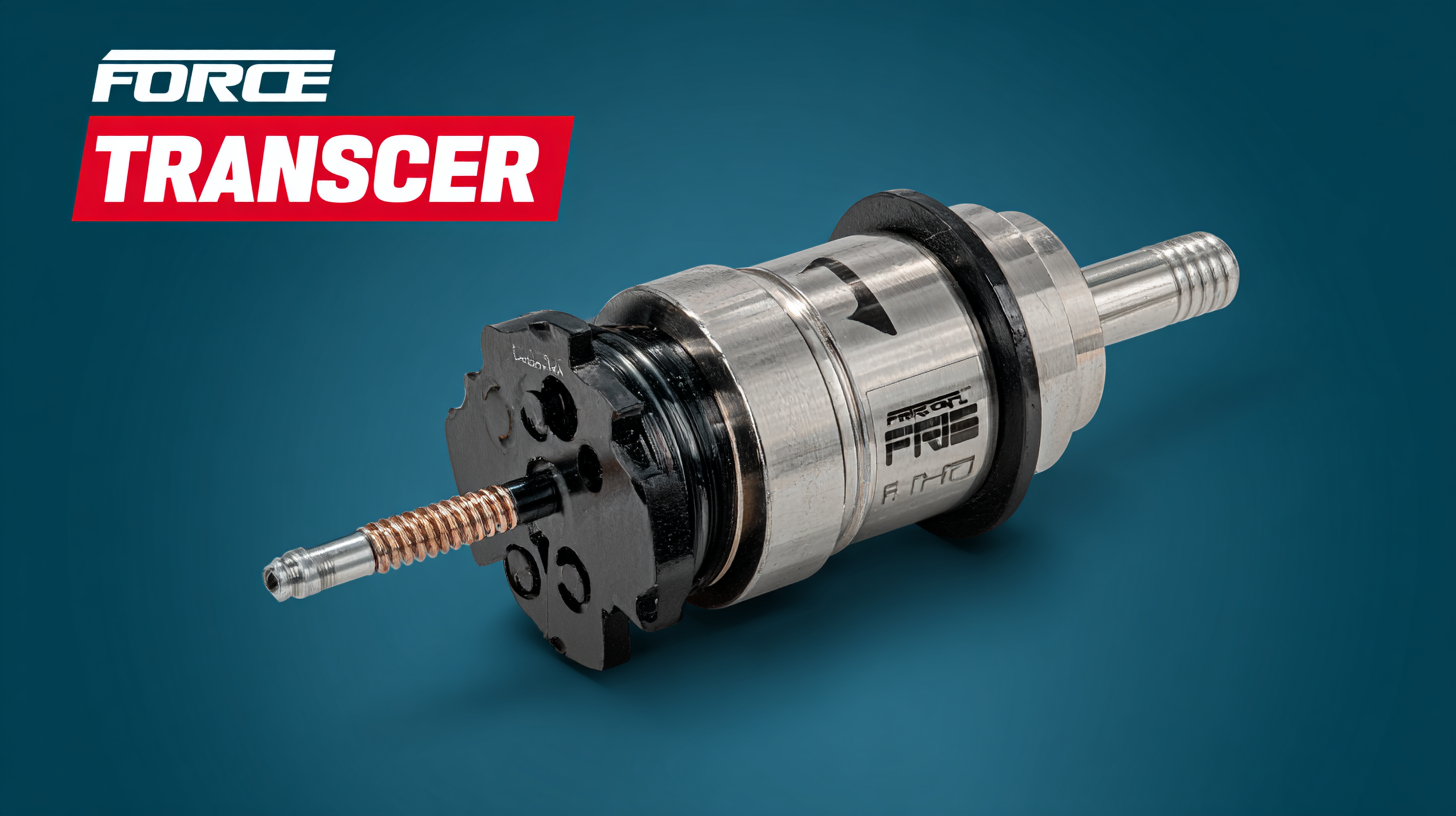

Force transducers play a pivotal role in various industries by accurately measuring force or weight. In manufacturing, they are crucial for quality control processes, ensuring products meet strict specifications. For instance, in automotive production, force transducers are used to test the strength of materials and components, ensuring safety and durability. They facilitate precise measurements during assembly, helping to prevent costly errors.

In the healthcare sector, force transducers are integral in medical devices, such as force-sensitive prosthetics that adapt to the user’s movement, providing enhanced mobility and comfort. These devices improve patient outcomes by allowing for real-time feedback and adjustments. Additionally, in research laboratories, force transducers enable scientists to measure the forces exerted during experiments, leading to significant advancements in material science and biomechanics. Their versatility and precision make them indispensable tools across industries, enhancing innovation and efficiency.

5 Reasons to Invest in High-Quality Force Transducers

When investing in high-quality force transducers, you gain significant advantages that can elevate your application results. Firstly, improved accuracy is a crucial benefit. High-quality models minimize errors, providing reliable data essential for critical applications, from industrial manufacturing to research environments. With precise measurements, you can ensure greater consistency and reliability, ultimately enhancing your operational efficiency.

Secondly, durability plays a vital role in selecting a force transducer. High-quality sensors are designed to withstand extreme conditions, including pressure, temperature fluctuations, and environmental factors. This durability not only extends the lifespan of the equipment but also reduces replacement costs and maintenance, leading to substantial long-term savings.

Tips: Always evaluate the specifications of force transducers against your application requirements. Look for features like temperature compensation and response time. Additionally, consider the manufacturer’s reputation and customer support services, as these can provide valuable assistance in the event of issues or inquiries.

Case Study: Enhancing Precision in Manufacturing with Force Sensors

The use of force sensors in precision manufacturing has seen significant advancements, particularly as industries strive for improved accuracy and efficiency. In a recent case study, integrating advanced force transducers allowed manufacturers to monitor machining processes in real-time, drastically minimizing tool wear and enhancing output quality. By employing physics-based modeling alongside information-theoretic approaches, operators gain insights that enable them to make informed decisions about tool settings and adjustment needs.

Moreover, the implementation of tri-axis force sensing technology further exemplifies the shift towards smart manufacturing. This system captures multi-directional forces acting on tools during machining, optimizing performance by maintaining the integrity of both the machinery and the materials being processed. Such innovations not only lead to higher product quality but also drive sustainability in operations by reducing energy consumption. As the industry evolves, the introduction of these precision sensors is crucial in navigating the complexities of modern manufacturing challenges, reinforcing the need for continual adaptation and technological integration in order to remain competitive.

5 Key Advantages of Choosing the Best Force Transducer for Your Applications

| Advantage | Description | Impact on Manufacturing | Example Application |

|---|---|---|---|

| High Accuracy | Ensures precise force measurements critical for quality control. | Reduces defects and increases product quality. | Calibration of robotic arms in assembly lines. |

| Wide Range of Measurement | Can measure both low and high forces, providing flexibility. | Accommodates various manufacturing processes. | Testing tensile strength of materials. |

| Compact Design | Easily integrates into various machinery without taking up much space. | Facilitates retrofitting older equipment. | Incorporation into small assembly devices. |

| Durability | Withstands harsh manufacturing environments. | Minimizes downtime due to sensor failures. | Usage in high-temperature processes. |

| Cost-Effectiveness | Provides a good balance of features versus cost. | Enables smart budgeting in equipment investments. | Choosing sensors for production line automation. |

The Economic Benefits of Choosing the Right Force Transducer

Selecting the right force transducer for your specific applications can lead to significant economic benefits. First and foremost, an accurate and reliable force transducer minimizes the risk of errors in measurements. This precision ensures that the processes relying on these measurements are optimized, reducing costly mistakes that can arise from incorrect data. When organizations utilize appropriate transducers, they are more likely to increase efficiency and maintain high-quality standards, ultimately translating to better product performance and increased customer satisfaction.

Moreover, investing in a high-quality force transducer can result in long-term savings. While budget constraints might tempt businesses to opt for cheaper alternatives, this often leads to frequent replacements and maintenance costs. A durable and precise force transducer requires less frequent servicing and has a longer lifespan, making it a wise investment. In addition, improved measurement performance can lead to enhanced process control and reduced waste, driving down operational costs and increasing profit margins. By prioritizing the selection of the best force transducer, organizations position themselves for economic success and sustainable growth.

Maximizing Performance: How Force Transducers Improve Data Accuracy

Force transducers play a crucial role in various applications by providing precise measurements of force, which directly enhances data accuracy. When selecting a force transducer, it is vital to choose one that aligns with the specific requirements of your application. High-quality transducers utilize advanced materials and technology, resulting in improved sensitivity and reduced measurement error. This ensures that the data collected is reliable and reflective of real-world conditions, which is essential for industries like aerospace, automotive, and robotics.

Moreover, the integration of force transducers into your systems creates opportunities for better performance and efficiency. By maximizing the accuracy of force measurements, these devices help engineers fine-tune their designs, optimize processes, and minimize waste. Such precision prevents the costly repercussions of errors during both development and production stages, ultimately leading to higher quality end products. As a result, investing in the best force transducer pays dividends in performance improvement and operational reliability.