sales@loadcellsensor.com

sales@loadcellsensor.com

Understanding the Key Technical Specifications of the Best Force Transducer and How to Choose the Right One

In the rapidly advancing technological landscape of 2025, the significance of precision measurement devices, such as force transducers, cannot be overstated. These devices are essential for accurately sensing and converting force into readable electrical signals, making them invaluable across various industries, from manufacturing to automotive engineering. As industries seek to enhance their automation processes and improve product quality, understanding the key technical specifications of the best force transducers becomes vital. This blog aims to delve into the critical aspects of selecting the right force transducer, highlighting the current trends in technology that influence their performance and application. By equipping yourself with this knowledge, you can make informed decisions that enable you to harness the full potential of force transducers in your operations.

Understanding the Functionality and Importance of Force Transducers in Industrial Applications

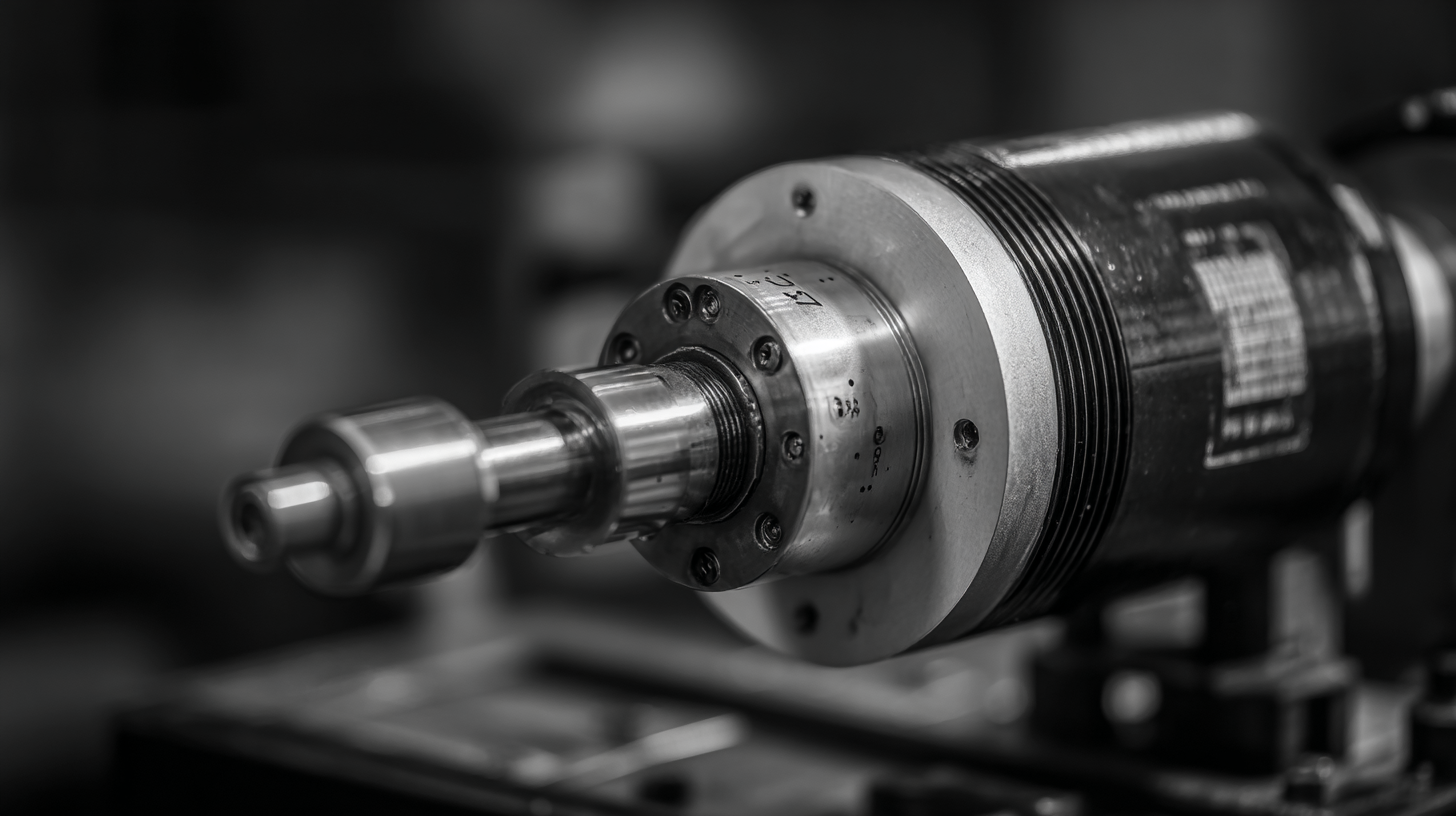

Force transducers play a vital role in various industrial applications by accurately measuring force, torque, and weight. Their functionality hinges on converting mechanical force into measurable electrical signals, enabling precise monitoring and control in manufacturing processes. Recent advancements in sensor data analysis highlight the importance of incorporating integrated force sensors, especially in critical areas like motor spindles, where real-time data is crucial for optimizing machining operations. A study published by CIRP underscores that implementing advanced monitoring systems can significantly enhance decision-making and operational efficiency in industry.

Furthermore, the evolution of capacitive sensors has had a profound impact on force transducer technology. The latest reviews indicate that high-performance capacitive sensors, enhanced by innovative materials and microstructure designs, are pivotal for developing force transducers with improved sensitivity and reliability. These technological advancements allow for better adaptability to varying operational conditions, thus ensuring consistent performance across diverse industrial applications. According to recent data, businesses that leverage these advanced sensors can achieve substantial reductions in downtime and improve overall productivity, illustrating the critical nature of selecting the right force transducer for operational success.

Understanding the Key Technical Specifications of the Best Force Transducer and How to Choose the Right One

| Specification | Details |

|---|---|

| Force Range | 0 to 500N |

| Accuracy | ±0.5% of Reading |

| Output Type | Analog Voltage / Current |

| Dimensions | 100mm x 50mm x 25mm |

| Temperature Range | -20°C to 80°C |

| Material | Aluminum Alloy |

| Calibration | Factory Calibration Certificate Provided |

| Response Time | < 1 ms |

Key Technical Specifications to Consider When Selecting a Force Transducer for Optimal Performance

When selecting a force transducer, understanding the key technical specifications is crucial for ensuring optimal performance in various applications. One of the most important specifications to consider is the transducer's measuring range, which should align with the maximum expected load. According to a report by

MarketsandMarkets, the global force sensor market size is projected to grow from USD 2.95 billion in 2020 to USD 4.38 billion by 2025, emphasizing the increasing demand for accurate and reliable force measurement across industries such as automotive and aerospace.

Another critical specification is the transducer’s accuracy and precision. Many industry leaders recommend looking for devices with an accuracy of at least 0.1% of the full-scale output. Additionally, the rise of digital force sensors has introduced parameters like signal-to-noise ratio (SNR), which should ideally exceed 60 dB for enhanced performance. A study published in the Journal of Experimental Mechanics found that utilizing transducers with high SNRs significantly reduces measurement uncertainty, leading to more dependable data for critical applications.

Another critical specification is the transducer’s accuracy and precision. Many industry leaders recommend looking for devices with an accuracy of at least 0.1% of the full-scale output. Additionally, the rise of digital force sensors has introduced parameters like signal-to-noise ratio (SNR), which should ideally exceed 60 dB for enhanced performance. A study published in the Journal of Experimental Mechanics found that utilizing transducers with high SNRs significantly reduces measurement uncertainty, leading to more dependable data for critical applications.

Temperature sensitivity is also a key consideration; transducers should be stable over the operating temperature range to prevent measurement drift. The American Society for Testing and Materials (ASTM) advises that for high-precision applications, temperature coefficients should be lower than 0.05%/°C. This ensures that the transducer maintains accurate readings despite environmental changes, which is a common challenge in various industrial settings.

Comparative Analysis of Top Global Manufacturers of Force Transducers and Their Unique Offerings

When exploring the market for force transducers, a comparative analysis of the leading global manufacturers reveals intriguing insights into their unique offerings. Each manufacturer embraces distinct technologies and applications, which can significantly influence the performance and reliability of force measurement solutions. For instance, companies like Load Cell Central have established a reputation for producing high-precision transducers that cater especially to industrial applications, emphasizing robustness and accuracy under demanding conditions. Their advanced calibration techniques set them apart, ensuring consistent performance in fluctuating environments.

On the other hand, manufacturers such as Honeywell focus on integrating cutting-edge digital technology into their force transducers. Their offerings often include features like wireless data transmission and advanced signal processing capabilities, which enhance usability and allow for real-time monitoring. This is particularly useful in sectors that require immediate feedback, such as aerospace and automotive testing. By understanding the unique strengths and innovations of these manufacturers, buyers can make informed decisions that align with their specific application needs and operational requirements.

Emerging Trends in Force Transducer Technology and Their Impact on Manufacturing Efficiency

Emerging trends in force transducer technology are reshaping the landscape of manufacturing efficiency. With advancements in materials science and digital integration, new force transducers are now more accurate, responsive, and versatile than ever before. These technologies not only enhance performance but also reduce operational costs by streamlining processes and minimizing errors. As industries increasingly adopt these innovations, the ability to measure and analyze forces in real-time offers unprecedented insights, allowing for smarter decision-making and improved product quality.

When selecting a force transducer, consider the specific applications within your manufacturing process. **Tip:** Evaluate the operating environment; factors like temperature and humidity can significantly influence performance. Additionally, assess the required accuracy and range to ensure the transducer meets your operational needs without compromising reliability.

Another important trend is the integration of IoT capabilities into force transducers. This connectivity allows for remote monitoring and data collection, which can further enhance efficiency and maintenance planning. **Tip:** Look for models that offer customizable data outputs and interfaces that easily integrate with your existing systems, ensuring seamless communication and data utilization across your operations.

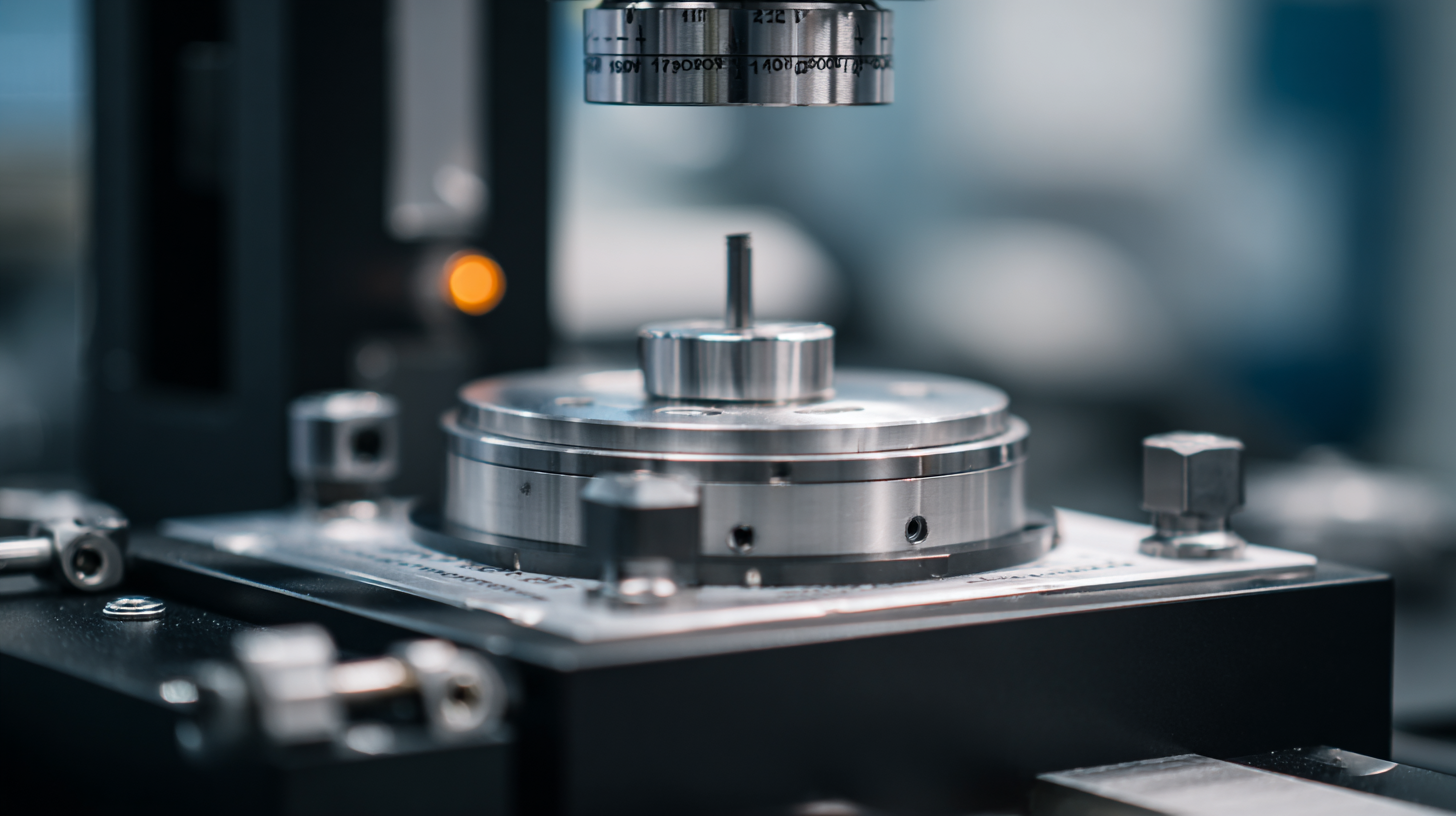

Best Practices for Maintaining and Calibrating Force Transducers in High-Volume Production Settings

In high-volume production settings, maintaining and calibrating force transducers is crucial for ensuring precision and consistency in measurements. Regular calibration intervals should be established based on manufacturers’ recommendations and production demands; studies show that environments with significant temperature variations can cause deviations in readings. According to a report by the Metrology Society, up to 25% of measurement errors in production can be attributed to improper calibration and maintenance practices. To minimize these errors, companies should implement standardized calibration protocols, leveraging benchmark scales and certified reference materials to validate the performance of transducers regularly.

Additionally, the optimal performance of force transducers relies heavily on environmental control. In a high-volume setting, dust, moisture, and temperature fluctuations can affect transducer readings, leading to inconsistent results. Industry guidelines suggest maintaining a controlled environment where humidity levels are kept below 60% and temperatures are stable within ±2°C of the operational range. Moreover, implementing routine maintenance checks, including visual inspections and functionality tests, can significantly reduce downtime and prolong the lifespan of force transducers. This proactive approach not only enhances product quality but also leads to cost savings, as highlighted in a study by the International Journal of Production Research, which reported that systematic maintenance can improve equipment reliability by up to 40%.