sales@loadcellsensor.com

sales@loadcellsensor.com

7 Key Tips to Maximize the Accuracy of Beam Type Load Cells for Optimized Performance

In the realm of industrial weighing and measurement, the accuracy of Beam Type Load Cells is paramount for ensuring operational efficiency and product quality. According to a recent report by the International Society of Automation, precision in load cell measurements can improve overall productivity by up to 30%, significantly reducing costs attributed to overloading or underloading. As industries increasingly rely on advanced load measurement technologies, optimizing the performance of Beam Type Load Cells becomes critical. This guide will explore seven key tips designed to enhance their accuracy, providing valuable insights for engineers and technicians seeking to implement best practices in load measurement systems. By optimizing your load cells, not only can you achieve consistent results, but you can also extend the lifespan of your equipment and minimize errors that could lead to costly disruptions.

Understanding Beam Type Load Cells and Their Applications

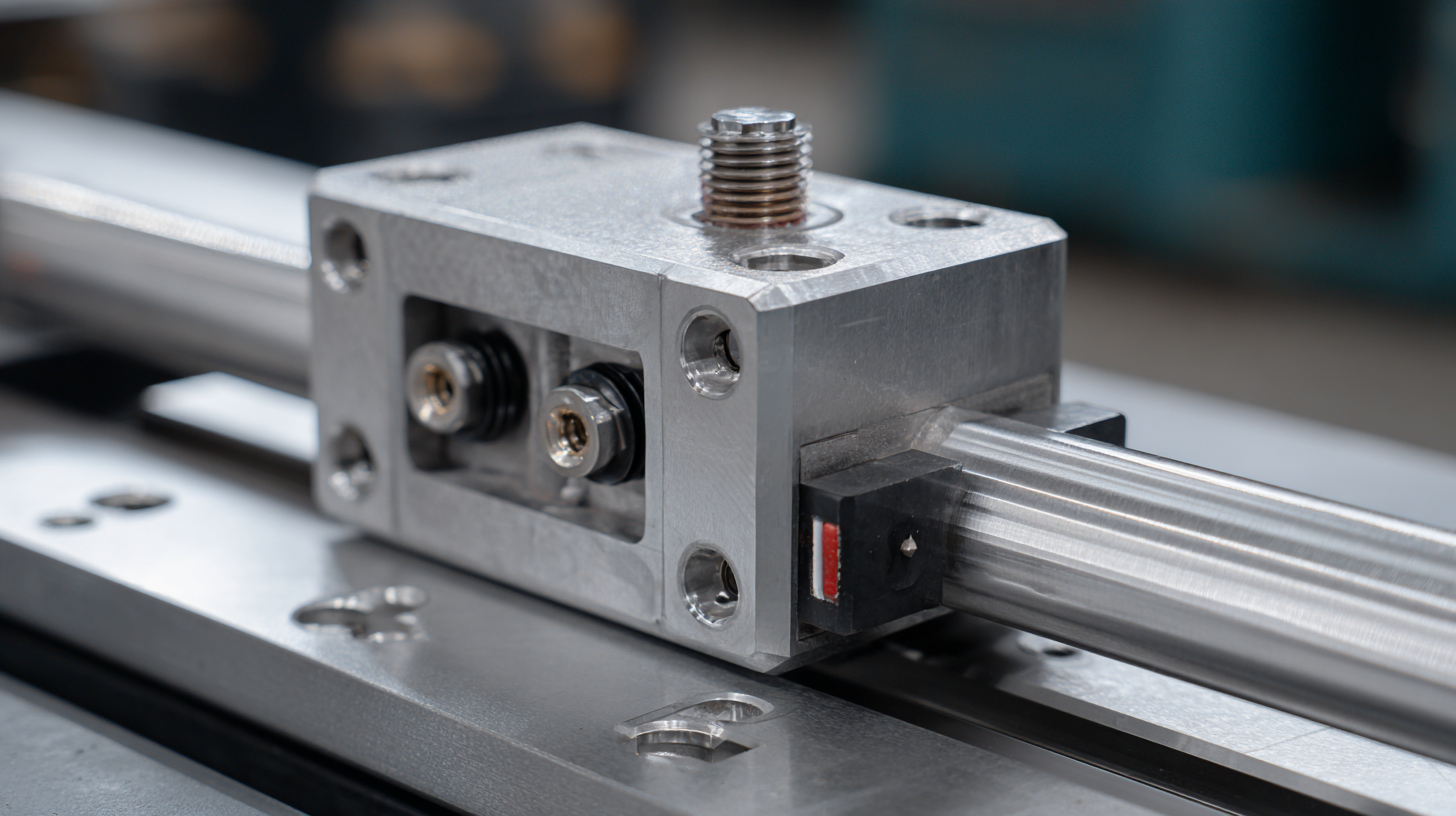

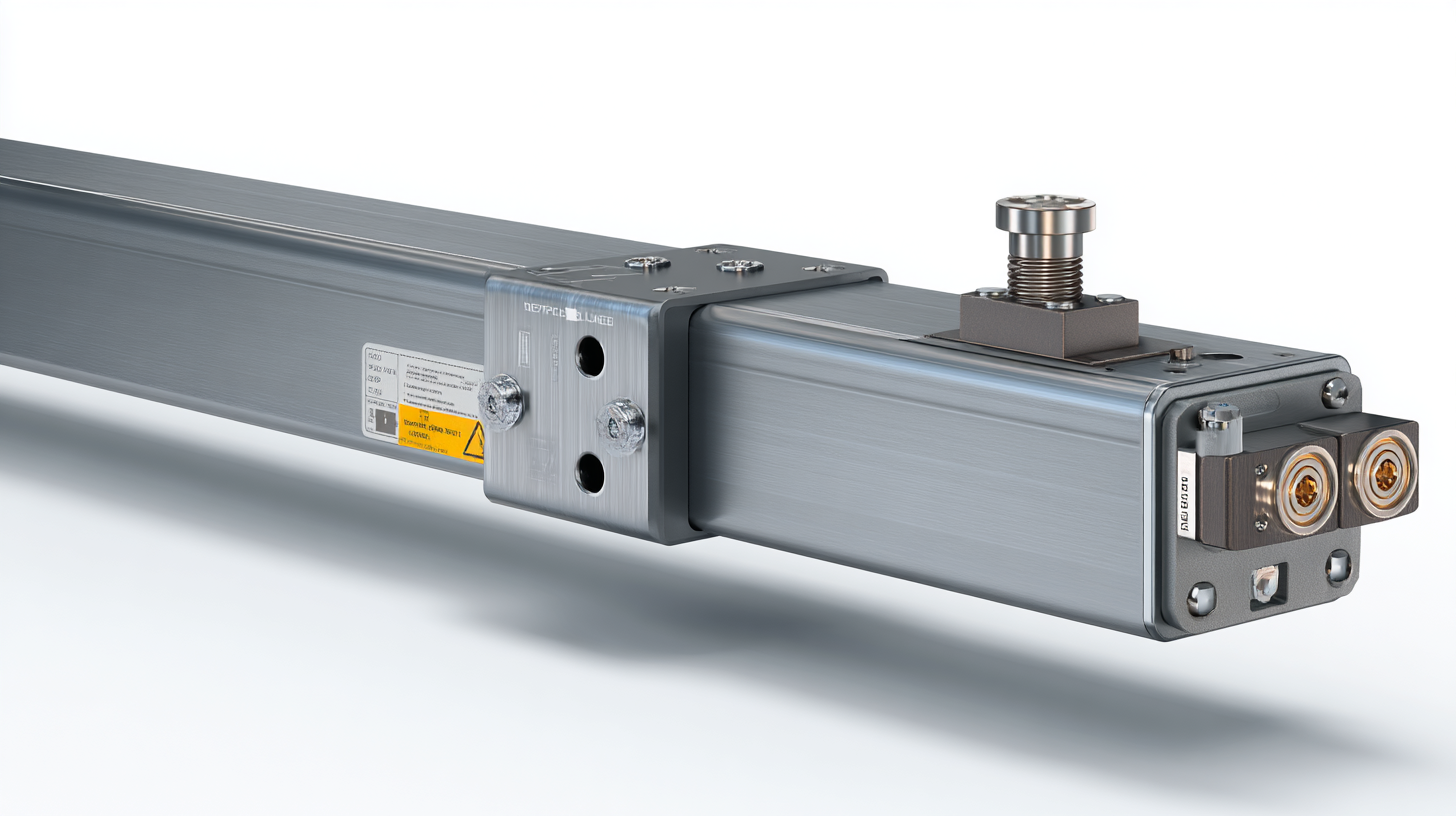

Beam type load cells are essential components in various industrial applications, providing precise measurements of force or weight. Typically constructed from materials such as aluminum or stainless steel, these load cells utilize the principles of strain gauge technology to detect deformation when a load is applied. Their design allows for high accuracy and durability, making them suitable for tasks ranging from platform scales to load monitoring systems in manufacturing environments.

The applications of beam type load cells are diverse, spanning across industries such as food and beverage, pharmaceuticals, and logistics. In the food industry, for example, accurate weight measurement is crucial for ensuring proper portions and compliance with regulatory standards. Similarly, in manufacturing, these load cells help optimize production processes by providing real-time data on material usage. As businesses seek to enhance efficiency and maintain quality control, understanding the functional capabilities and proper implementation of beam type load cells becomes vital for achieving sustained operational performance.

7 Key Tips to Maximize the Accuracy of Beam Type Load Cells for Optimized Performance

| Tip | Description | Impact on Accuracy | Recommended Practices |

|---|---|---|---|

| 1. Proper Installation | Ensure load cells are installed in accordance with manufacturer guidelines. | Critical for maintaining the integrity of measurements. | Use alignment tools and check for levelness. |

| 2. Environmental Considerations | Protect load cells from extreme temperatures and humidity. | Prevents drift and ensures consistent readings. | Install in climate-controlled environments if possible. |

| 3. Regular Calibration | Perform routine calibration checks to ensure accuracy. | Essential for identifying and correcting drift. | Schedule annual or bi-annual calibration with a certified technician. |

| 4. Load Cell Selection | Choose load cells suitable for the specific application. | Directly influences accuracy and performance. | Consult with experts to match capacity with expected loads. |

| 5. Minimize Mechanical Stress | Avoid applying accidental loads or forces beyond design limits. | Prevent physical damage and measurement errors. | Implement safety limits and overload protection systems. |

| 6. Signal Conditioning | Use proper signal conditioning to enhance measurement accuracy. | Improves resolution and reduces noise in readings. | Employ high-quality amplifiers and filtering techniques. |

| 7. Load Distribution | Ensure that loads are evenly distributed across the load cell. | Minimizes localized stress that can skew readings. | Use spreader beams or platforms for even load distribution. |

Key Factors Influencing the Accuracy of Beam Type Load Cells

When it comes to beam type load cells, accuracy is paramount for ensuring optimal performance in various applications. Several key factors contribute to the accuracy of these devices, starting with proper installation. Ensuring that the load cell is aligned correctly and securely mounted is essential, as misalignment can introduce errors in measurement. Furthermore, the load must be evenly distributed across the cell to avoid stress concentrations that can skew results.

Environmental conditions also play a critical role in the performance of load cells. Factors such as temperature fluctuations and humidity can affect the materials of the load cell, leading to drift or hysteresis in measurements. Regular calibration is vital to mitigate these effects, and utilizing a well-designed loading frame can help maintain a stable environment around the load cell. Lastly, selecting the appropriate load cell for the specific application is crucial, as different designs and materials are suited for different types of loads and conditions, ultimately impacting the accuracy of the readings obtained.

Key Factors Influencing the Accuracy of Beam Type Load Cells

This chart illustrates the impact of different factors on the accuracy of beam type load cells. The data highlights the significance of calibration, temperature stability, mechanical design, and environmental factors.

Calibration Techniques for Enhanced Precision in Load Cells

Calibration is a critical process that significantly impacts the performance and accuracy of beam type load cells. By employing precise calibration techniques, users can ensure that their load cells operate at peak efficiency. One effective method involves using standardized weights to calibrate the load cell, allowing for direct comparison between measured and actual loads. This step not only fine-tunes the load cell's response but also helps to identify any potential discrepancies in readings.

Calibration is a critical process that significantly impacts the performance and accuracy of beam type load cells. By employing precise calibration techniques, users can ensure that their load cells operate at peak efficiency. One effective method involves using standardized weights to calibrate the load cell, allowing for direct comparison between measured and actual loads. This step not only fine-tunes the load cell's response but also helps to identify any potential discrepancies in readings.

Another tip for enhancing precision is to frequently check the calibration at regular intervals or after any substantial environmental changes. Load cells can drift over time due to factors such as temperature fluctuations and mechanical stress. Setting up a routine calibration schedule can help mitigate these issues and maintain reliable data. Additionally, utilizing software that can track calibration history and performance metrics can lead to informed decision-making for future calibrations.

Finally, ensuring that the load cell is properly installed and configured is vital for accurate operation. Misalignment or improper mounting can lead to erroneous measurements. Before finalizing the installation, double-check the alignment and make necessary adjustments to minimize parallax errors. By following these calibration techniques, the accuracy of beam type load cells can be maximized, ultimately optimizing overall performance.

Common Mistakes to Avoid for Optimal Load Cell Performance

When it comes to ensuring the optimal performance of beam type load cells, avoiding common mistakes is essential. One prevalent error is improper load framing, which can lead to inaccurate readings. According to a report by the International Society of Automation, misalignment can cause measurement errors up to 5%, significantly compromising the reliability of data. Ensuring that the load cell is perfectly aligned with the applied load is crucial for accurate measurements.

Another mistake involves insufficient calibration checks. Regular calibration is vital to maintaining load cell accuracy. A study conducted by the National Institute of Standards and Technology recommends calibrating load cells at least once every six months to account for drift and environmental changes. This proactive approach guarantees that you're working with precise measurements tailored to your applications.

Tip: Consistently monitor the environmental conditions surrounding your load cell installation. Variations in temperature and humidity can affect performance and lead to biases in measurement. Moreover, employing adequate shielding against electromagnetic interference can enhance load cell accuracy. By prioritizing these considerations, you can significantly bolster the performance of your beam type load cells and minimize common pitfalls.

Maintenance Practices to Ensure Long-lasting Accuracy of Load Cells

To maintain the accuracy of beam type load cells, it's crucial to implement effective maintenance practices that ensure long-lasting performance. Regular calibration is one of the fundamental steps; studies indicate that annual calibrations can reduce measurement errors by up to 15%. Furthermore, maintaining an optimal environmental condition—such as controlling temperature and humidity—can prevent drift in measurements, which is essential for applications that demand precision. According to industry reports, environmental factors can impact accuracy by as much as 10% if not properly managed.

Another critical aspect of maintaining load cell accuracy is the inspection of connections and wiring. Loose or corroded connections can introduce erroneous readings. Data suggests that routine inspections can identify wiring issues before they lead to significant measurement errors, thus preserving performance integrity. Additionally, training operators to follow proper handling protocols can mitigate human error, which accounts for approximately 30% of inaccuracies in load measurement systems. By integrating these maintenance practices, businesses can leverage technology and improve the reliability of their load cells, ultimately optimizing operational efficiency.

Related Posts

-

Exploring Alternative Load Cell Solutions for Optimizing Tensile and Compressive Testing

-

Unlocking Success with Thin Load Cells Effective Ways to Identify Quality Suppliers

-

Top Strategies for Selecting the Best 5kg Load Cell for Your Business Needs

-

Ensuring Excellence: Global Industry Standards for the Best Single Point Load Cells

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide

-

Overcoming Industry Standards: How to Choose the Best Compression Load Cell Amidst Common Challenges