sales@loadcellsensor.com

sales@loadcellsensor.com

Maximizing Precision: Key Techniques for Effective Torque Sensor Implementation

In the ever-evolving landscape of industrial automation, the significance of precise measurements cannot be overstated, especially when it comes to torque management. According to a recent report by MarketsandMarkets, the global torque sensor market is projected to reach USD 1.2 billion by 2025, driven by the increasing need for accurate torque measurements in various applications, including automotive, aerospace, and manufacturing. Implementing effective torque sensor techniques is crucial for optimizing performance and ensuring the reliability of mechanical systems. This tutorial aims to delve deep into the key methodologies for maximizing precision in torque sensor implementation, empowering engineers and technicians to harness the full potential of these indispensable devices in their operations.

Exploring Alternative Torque Sensor Technologies for Enhanced Performance

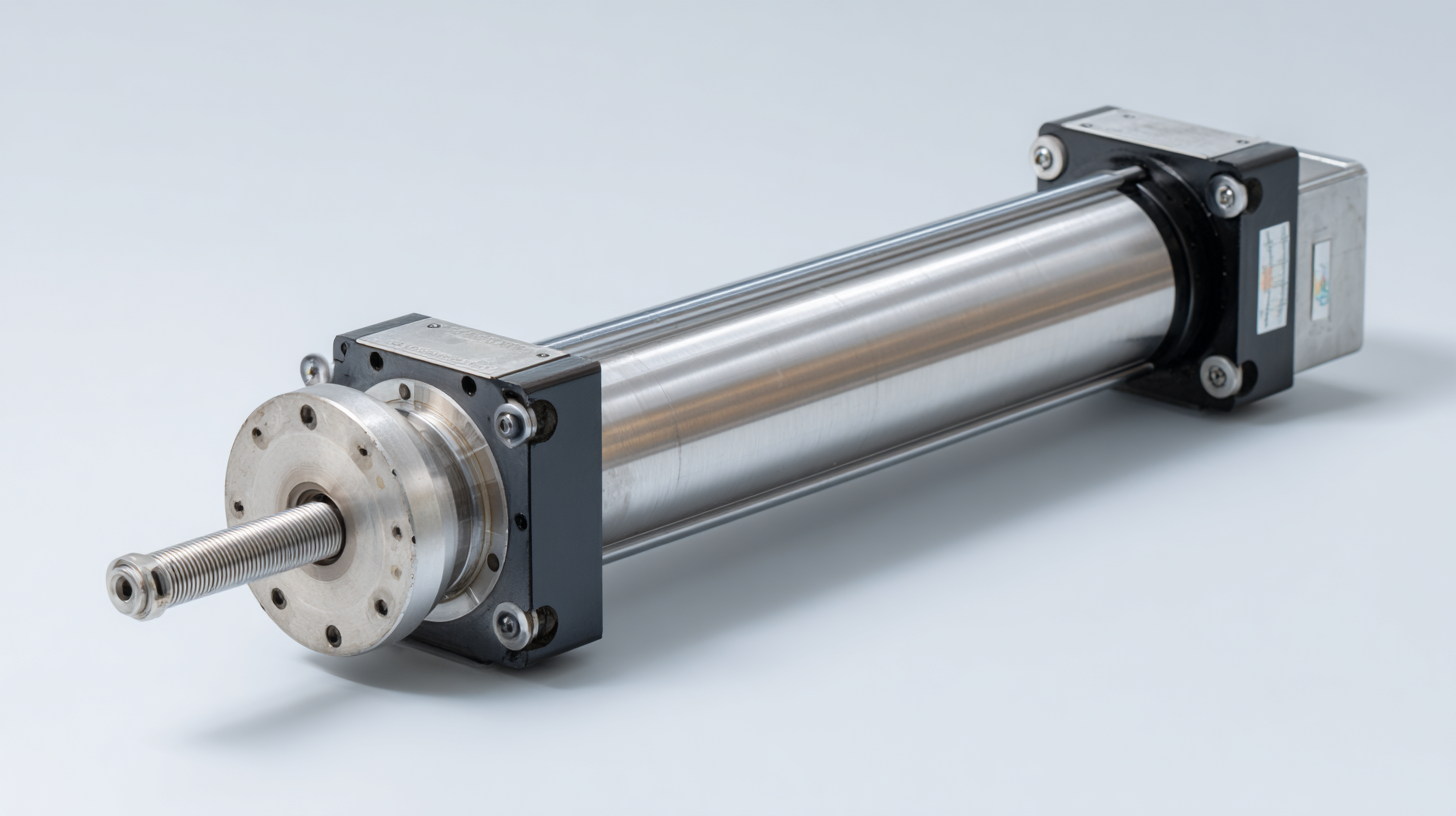

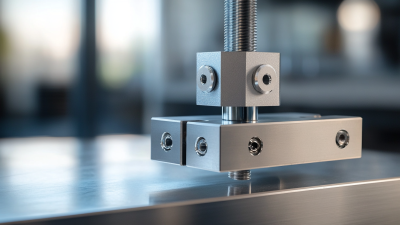

When it comes to enhancing the performance of torque sensors, exploring alternative technologies is vital. Traditionally, strain gauge-based torque sensors have been the go-to solution due to their robustness and accuracy. However, advancements in technology have paved the way for alternatives such as optical torque sensors, magnetic sensors, and solid-state devices.

Optical torque sensors utilize light transmission to measure torsion, providing high fidelity for dynamic applications. Meanwhile, magnetic torque sensors leverage variations in magnetic fields to deliver reliable measurements in harsh environments.

Adopting these alternative technologies can significantly improve performance in specific applications. For instance, in environments with extreme temperature fluctuations, solid-state devices offer durability and resilience, ensuring consistent performance. Furthermore, these innovative sensors contribute to reduced maintenance costs and increased operational efficiency, making them a smart choice for industries demanding high precision in torque measurement.

By investigating these alternatives, engineers and designers can optimize their systems and achieve greater accuracy and reliability in torque monitoring, ultimately leading to improved overall performance.

Comparative Analysis of Digital and Analog Torque Sensors

When implementing torque sensors, understanding the differences between digital and analog options is crucial for achieving optimal precision. Digital torque sensors offer enhanced accuracy and the ability to process signals more effectively, making them ideal for applications where data integrity and analysis are paramount. On the other hand, analog torque sensors are often simpler and more affordable, providing reliable readings in less complex environments.

**Tip:** When selecting between digital and analog torque sensors, consider the specific requirements of your application, including the need for real-time data processing and the operating conditions. Digital sensors may excel in high-demand environments due to their superior data fidelity.

Another key factor to consider is the calibration process. Digital sensors usually come with advanced software that aids in calibration, which can significantly reduce setup time and errors. Conversely, analog sensors may require more manual adjustments, which can introduce variability.

**Tip:** Regularly assess the calibration of your torque sensors, regardless of type. Consistent checks can ensure that your measurements remain accurate and your operations efficient, preventing costly errors down the line.

Innovative Applications of Wireless Torque Sensors in Modern Industry

In modern industry, the innovative application of wireless torque sensors is transforming operational practices, particularly in automotive engineering. As the automotive sector integrates hybrid systems and electric vehicle innovations, the demand for precision measurement technologies is surging. The global torque sensor market is projected to reach USD 13.0 billion by 2033, reflecting the increasing reliance on advanced sensors to improve vehicle performance and safety features. These sensors enable real-time monitoring of rotary torque, leading to enhanced efficiency in production and the development of smarter vehicles.

Furthermore, the advent of Industry 4.0 is set to revolutionize production plants, with wireless torque sensors playing a crucial role in this transformation. As companies strive for higher quality and productivity, the implementation of these sensors can significantly contribute to the manufacturing process. The Force & Torque Sensor Market is anticipated to reach USD 35.13 billion by the end of 2032, underscoring the rapid adoption of such technologies across various industries, including aerospace and industrial sectors. This trend demonstrates a collective shift towards smarter technologies that not only optimize production but also align with eco-friendly practices.

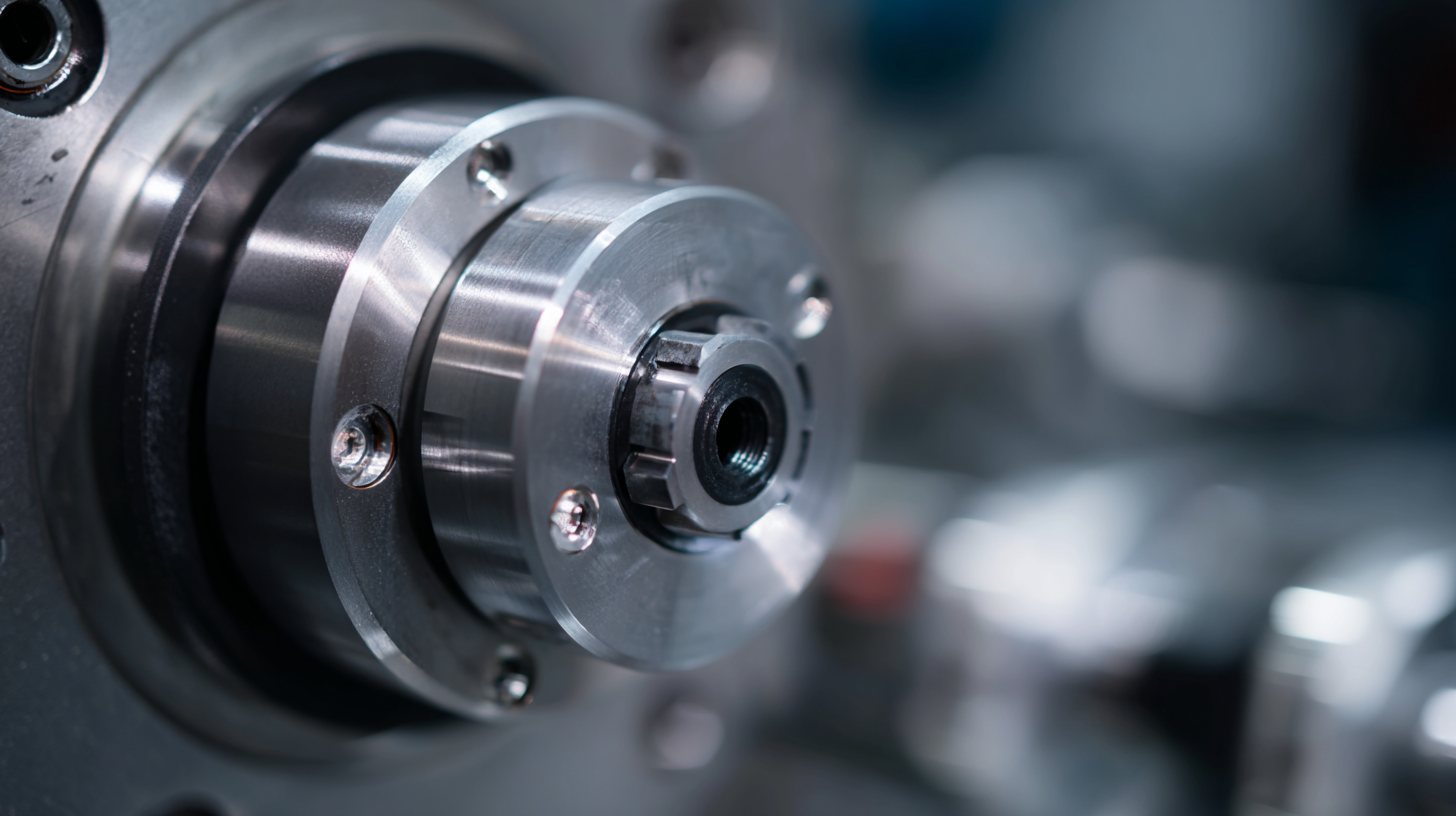

Selecting the Right Sensor: Key Factors to Consider in Alternative Technologies

When selecting the right torque sensor for your application, several key factors must be considered to ensure optimal performance. First, assess the type of load and the range of torque that will be experienced during operation. Different technologies, such as strain gauge, piezoelectric, and magnetoresistive sensors, each offer distinct advantages based on their sensitivity, accuracy, and measurement range. Understanding the specific requirements of your application will guide you toward the best technology.

Another critical factor is the environmental conditions in which the sensor will operate. Factors such as temperature, humidity, and exposure to chemicals can significantly impact sensor performance. For instance, piezoelectric sensors might excel in dynamic applications but may not be suitable in harsh environments where temperature fluctuations are prevalent. Additionally, consider the ease of integration into your existing systems. The compatibility of the sensor with your data acquisition system and the availability of necessary signal conditioning equipment can greatly influence your selection process, ensuring seamless implementation and effective data collection.

Maximizing Precision: Torque Sensor Performance Comparison

This chart compares the performance of various torque sensor technologies based on precision, response time, and cost. The data highlights the trade-offs necessary in selecting the right sensor for specific applications.

Cost-Effectiveness of Alternative Torque Sensors: Balancing Quality and Budget

When implementing torque sensors, balancing cost and quality is essential for achieving optimal performance in various applications. According to a recent market analysis by MarketsandMarkets, the torque sensor market is projected to reach $1.75 billion by 2026, reflecting a growing demand for accurate measurement tools in industries such as automotive, aerospace, and manufacturing. However, not all torque sensors are created equal, and choosing the right type—be it strain gauge, piezoelectric, or optical—can significantly impact both operational efficiency and budget allocation.

Cost-effective alternatives to traditional torque sensors often feature advanced materials and designs that enhance their durability and accuracy while reducing manufacturing expenses. A report by Technavio highlights that adopting these innovative sensors can lead to a 20% reduction in overall operational costs without compromising data reliability. Furthermore, the integration of IoT technology with cost-efficient torque sensors enables real-time monitoring and data analysis, providing organizations with actionable insights while maintaining a strict budget. By understanding the available options and their implications on both quality and cost, companies can make informed decisions that align with their fiscal goals.

Related Posts

-

Navigating the Global Standards for Best Torque Sensor Imports and Exports

-

Unleashing China's Manufacturing Excellence: A Deep Dive into the Best Torque Sensor Innovations

-

Leading Factory in China Innovating Torque Transducers for Global Markets

-

Precision Engineering: Chinese Manufacturing Innovating Global Torque Transducer Solutions

-

Explore Cutting-Edge Weight Sensors at the Record-Breaking 137th Canton Fair!

-

2025 Trends: How to Choose the Best 5kg Load Cell for Global Sourcing Success