sales@loadcellsensor.com

sales@loadcellsensor.com

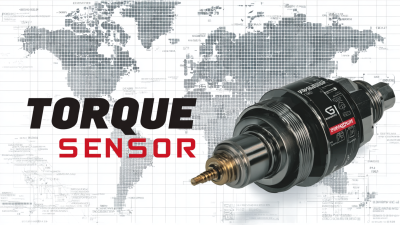

Understanding Motor Torque Sensors: Key Benefits and Applications Explained

In the realm of precision engineering and automation, the significance of monitoring mechanical parameters cannot be overstated. One such critical parameter is torque, a measure of rotational force that plays a pivotal role in the performance and efficiency of various machinery and systems. Enter the Motor Torque Sensor, a sophisticated device designed to measure torque in electric motors and related applications. Understanding the function and advantages of these sensors is vital for industries ranging from automotive to robotics, where accurate torque measurement is essential for optimizing performance and ensuring safety.

Motor Torque Sensors provide invaluable data that contribute to the effective management and control of motor functions. By offering real-time feedback, these sensors allow engineers and operators to fine-tune performance, improve energy efficiency, and extend the lifespan of equipment. Furthermore, their applications span various sectors, including manufacturing, aerospace, and renewable energy, highlighting their versatility and importance in modern technology. This article will delve into the core benefits of Motor Torque Sensors, exploring how they enhance operational capabilities and drive innovation across multiple disciplines.

Key Concepts of Motor Torque Sensors Explained

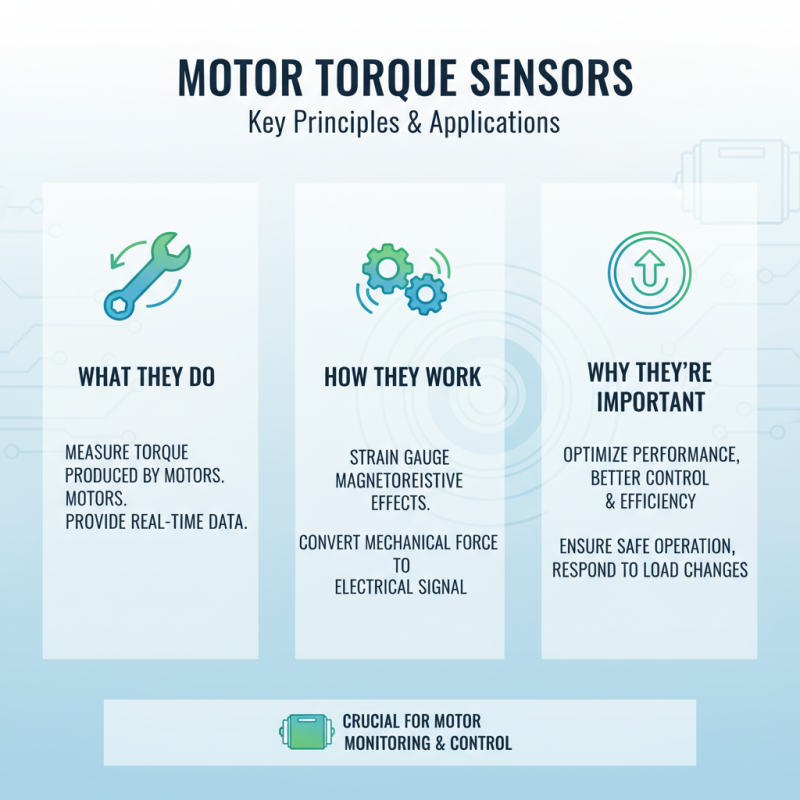

Motor torque sensors are crucial devices designed to measure the torque produced by motors. These sensors operate on various principles, including strain gauge technology and magnetoresistive effects, providing accurate real-time data that is essential for the monitoring and optimization of motor performance. By quantifying the torque, these sensors enable better control of motor functions, ensuring they operate within safe limits and respond appropriately to load changes.

The importance of understanding motor torque sensors lies in their wide range of applications across various industries. For instance, in electrical and mechanical engineering, these sensors are used to enhance system efficiency and performance in automotive and aerospace sectors. They assist in precision engineering tasks, ensuring that machinery operates optimally and reduces the risk of mechanical failure. Additionally, motor torque sensors play a vital role in research and development, aiding in the design of more efficient motors and drivetrains. By providing crucial feedback, they enable engineers to make informed decisions, ultimately leading to advancements in technology and innovation.

Types of Motor Torque Sensors and Their Functionality

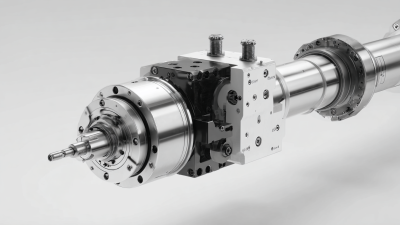

Motor torque sensors are essential devices that measure the torque output of a motor, providing critical data for various applications. There are several types of torque sensors available, each designed with unique functionalities to cater to specific needs. One common type is the strain gauge sensor, which utilizes the principle of deformation to measure torque. When a force is applied, the material changes shape, and this deformation is converted into an electrical signal that correlates with the torque level.

Another popular type is the magnetoelastic torque sensor. This device measures the magnetic properties of a material that change under stress. When torque is applied, these properties shift, allowing the sensor to provide accurate readings. These sensors are especially useful in environments that require high precision and reliability, maintaining performance under challenging conditions.

Additionally, rotary torque sensors offer continuous measurement capabilities, making them ideal for real-time monitoring in automated systems. Each type of motor torque sensor plays a vital role in enhancing operational efficiency and ensuring the longevity of machinery across various industries.

Advantages of Using Torque Sensors in Motor Applications

Torque sensors play a crucial role in motor applications, providing valuable insights that enhance performance and reliability. One of the main advantages of using torque sensors is their ability to offer real-time data on the torque output of motors. This immediate feedback is essential for optimizing motor control strategies, which can lead to improved efficiency and reduced energy consumption. By continuously monitoring the torque, engineers can adjust parameters to ensure that the motor operates within its optimal range, minimizing wear and tear and extending the lifespan of the equipment.

Another significant benefit of torque sensors is their capacity to enhance the safety of motor systems. By accurately measuring torque, these sensors can help detect abnormalities such as overloads, which might indicate a malfunction or impending failure. Addressing these issues before they escalate not only protects the motor but also safeguards the entire system and prevents costly downtime. Furthermore, torque sensors are critical in applications where precise control is necessary, such as robotics and automation, where even slight variations in torque can lead to performance discrepancies. This capability makes them indispensable in modern engineering solutions, ensuring both operational excellence and reliability.

Common Applications of Motor Torque Sensors in Industry

Motor torque sensors play a crucial role in various industrial applications, providing accurate measurements for optimizing performance and ensuring safety. One of the primary applications of these sensors is in the automotive industry, where they are integral to electric vehicles (EVs) and hybrid systems. According to a recent market analysis, the global automotive torque sensor market is projected to grow at a CAGR of 7.5% between 2023 and 2030, driven by the increasing demand for advanced driver assistance systems (ADAS) and the rising adoption of EVs. By measuring the torque output of motors, manufacturers can enhance energy efficiency and improve vehicle dynamics.

Another significant application is in robotics and automation, where precise torque measurements are essential for effective motion control. In this sector, torque sensors facilitate better force feedback in robotic arms, enabling them to perform intricate tasks with high accuracy. Data from industry reports suggest that the robotics market is expected to reach $210 billion by 2025, illustrating a strong trend towards automation across various sectors. Implementing motor torque sensors in these systems can lead to enhanced performance and reduced wear on mechanical components.

Tips for integrating motor torque sensors include ensuring proper calibration to enhance the accuracy of measurements and regularly assessing the sensor's performance to anticipate maintenance needs. Additionally, selecting the appropriate type of torque sensor, whether it be rotary or static, based on the specific application requirements can significantly impact overall system efficiency. Understanding these factors can lead to better results and reduced downtime in operations.

Understanding Motor Torque Sensors: Key Benefits and Applications Explained

| Application Area | Key Benefits | Typical Torque Range | Common Sensor Type |

|---|---|---|---|

| Automotive Industry | Improved vehicle performance monitoring and diagnostics | 0.1 - 1000 Nm | Strain Gauge |

| Aerospace Engineering | Enhanced safety through precise torque measurements | 0.01 - 500 Nm | Piezoelectric |

| Industrial Machinery | Increased equipment reliability and efficiency | 0.5 - 2000 Nm | Rotary Torque Sensor |

| Robotics | Precision control and feedback in robotic arms | 0.1 - 300 Nm | Bending Beam Sensor |

| Renewable Energy | Monitoring torsional loads in wind and solar energy systems | 1 - 1500 Nm | Wireless Torque Sensor |

Future Trends and Innovations in Torque Sensor Technology

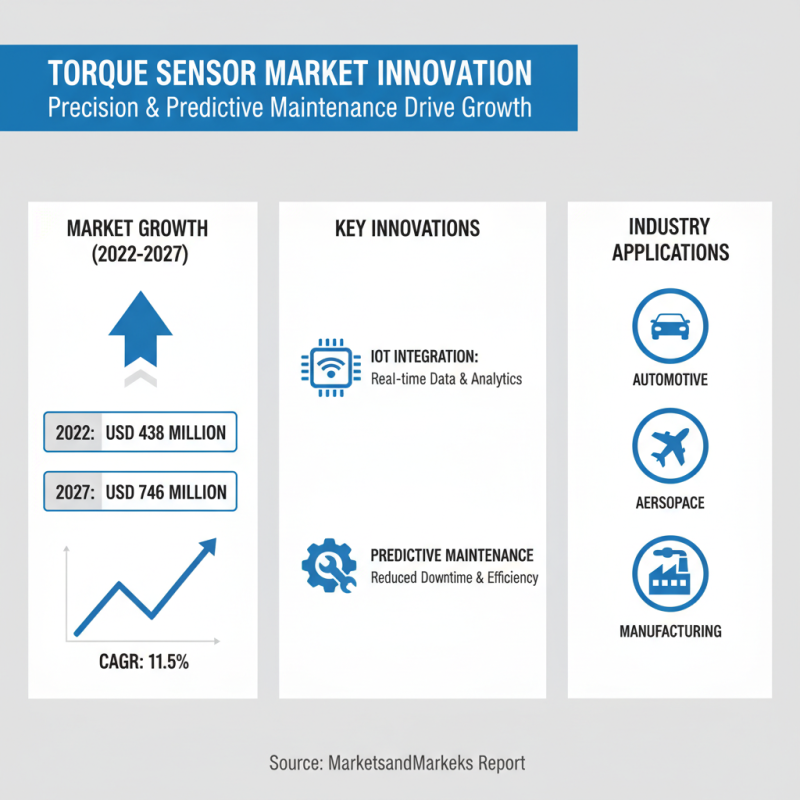

As the demand for precision in various industrial applications continues to rise, torque sensor technology is undergoing significant innovation. According to a report by MarketsandMarkets, the torque sensor market is projected to grow from USD 438 million in 2022 to USD 746 million by 2027, at a compound annual growth rate (CAGR) of 11.5%. This growth is largely driven by advancements in sensor technology, including the integration of IoT capabilities, which allow for real-time data collection and analysis. These innovations enable industries such as automotive, aerospace, and manufacturing to enhance their operational efficiency and reduce downtime through predictive maintenance.

Future trends in torque sensor technology are set to transform how these devices are utilized. The introduction of wireless sensors is particularly noteworthy, as they eliminate the need for cumbersome cabling, making installations easier and reducing wear and tear on equipment. Additionally, developments in materials science are leading to more robust and lightweight sensors that can withstand harsher environments without compromising accuracy. Reports highlight that by 2025, the adoption of wireless torque sensors may see a significant increase, reflecting a broader shift towards automation and remote monitoring in industrial processes. As these technologies evolve, they promise to unlock new applications and improve the accuracy and reliability of torque measurements across various sectors.

Related Posts

-

Revolutionizing Measurements An Insight into the 2025 Trends for Best Rotary Torque Transducers

-

Navigating the Global Standards for Best Torque Sensor Imports and Exports

-

Unleashing China's Manufacturing Excellence: A Deep Dive into the Best Torque Sensor Innovations

-

How to Select the Right Torque Sensor for Enhanced Precision in Industrial Applications

-

Understanding the Importance of Shaft Torque Sensors in Modern Engineering Practices

-

Navigating the 2025 Technology Trends in Load Cells Your Ultimate Guide to Best Miniature Load Cells