sales@loadcellsensor.com

sales@loadcellsensor.com

Navigating Industry Standards for Best Weight Transducer and Its Challenges

In the rapidly evolving landscape of industrial applications, the significance of weight transducers cannot be overstated. According to the latest report from the International Society of Automation (ISA), the demand for precise weight measurement in various sectors, including manufacturing, logistics, and pharmaceuticals, is projected to grow by over 7% annually through 2025. This increase underscores the urgent need for manufacturers and businesses to navigate the complex industry standards associated with weight transducers effectively. However, understanding these standards poses significant challenges due to the diverse applications and technologies involved.

This blog aims to provide a comprehensive guide on selecting the best weight transducer while overcoming prevalent industry hurdles. By delving into the intricacies of compliance, accuracy, and compatibility, we will empower stakeholders to make informed decisions that enhance operational efficiency and quality control.

Understanding the Importance of Industry Standards for Weight Transducers

In the realm of weigh transducers, adhering to industry standards is paramount for ensuring accuracy, reliability, and interoperability. These standards not only elevate the quality of measurements but also facilitate the integration of weight transducers into the growing Internet of Things (IoT) ecosystem. According to research, about 75% of companies implementing IoT solutions cite adherence to industry standards as critical to their success. Protocols such as MQTT and CoAP enable seamless communication between devices, which is essential when weight transducers are utilized in applications ranging from logistics to manufacturing.

Furthermore, the significance of industry standards extends beyond mere compliance; it enhances safety and operational efficiency. For instance, in the transportation sector, standardized weight transducers help ensure that vehicles remain within legal weight limits, thereby promoting safety on the roads. Data shows that improper weight management contributes to approximately 30% of transportation-related accidents, underscoring the need for precise weight measurement solutions. By navigating these industry standards, manufacturers can mitigate challenges and deliver products that meet both regulatory requirements and customer expectations, ultimately driving innovation in the weight transducer market.

Key Features to Consider When Comparing Different Weight Transducer Models

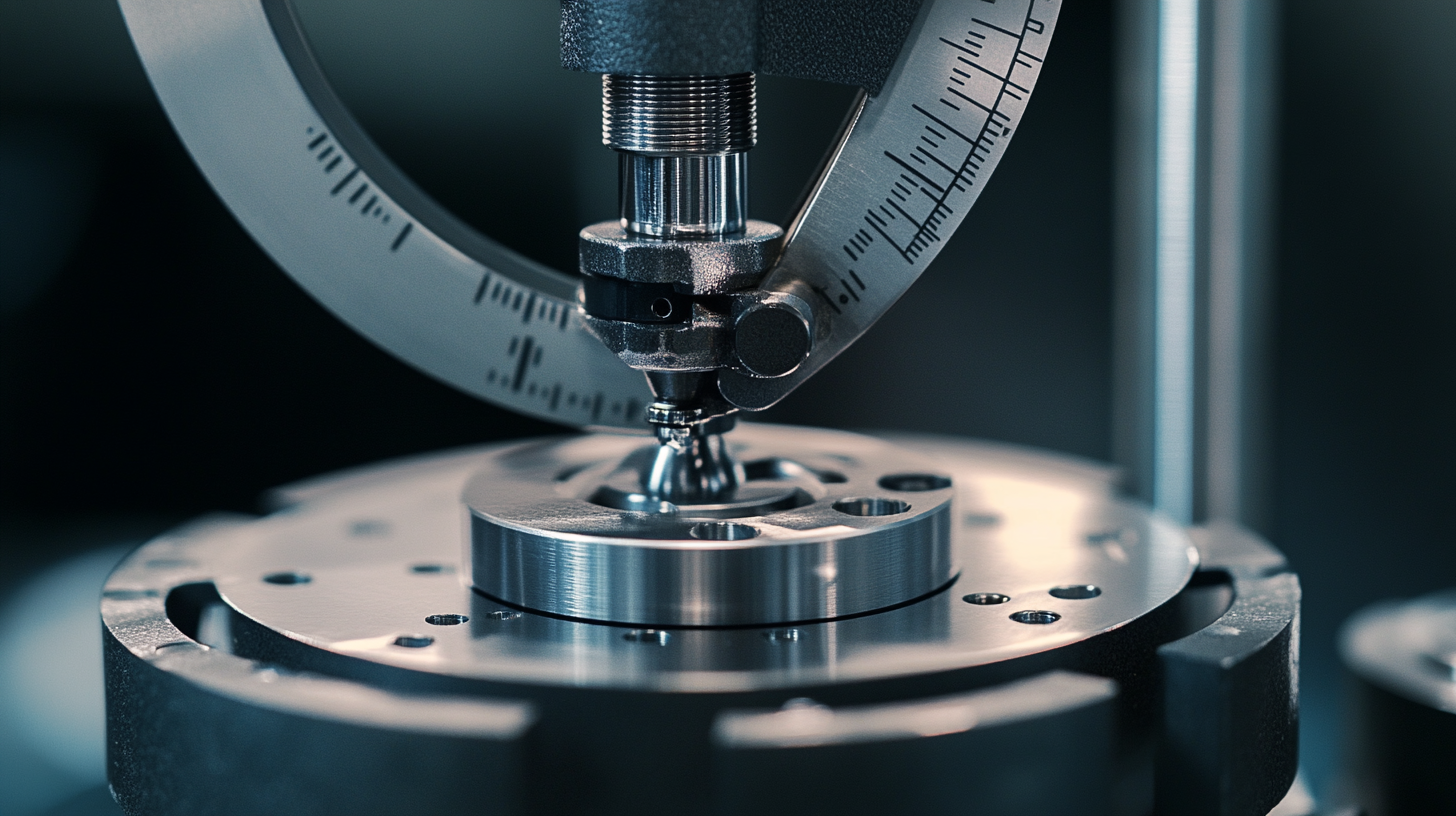

When comparing different weight transducer models, it's crucial to consider key features that impact performance and user experience. One primary aspect is the accuracy and precision of the transducer. High-quality models often feature advanced sensing technologies that optimize weight measurements, making them essential for applications requiring strict adherence to industry standards. Additionally, look for models that boast a high capacity and durability, ensuring they can handle various loads while withstanding harsh environments.

Another significant factor is connectivity and integration capabilities. Many modern weight transducers offer additional features such as wireless connectivity, allowing for seamless data transfer to other devices for analysis and monitoring. This can greatly enhance operational efficiency and accuracy, particularly in environments where real-time tracking of weight data is crucial. Furthermore, users should evaluate the ease of installation and maintenance, as these aspects can influence the overall functionality and longevity of the transducer. By keeping these key features in mind, you can make informed decisions when selecting the best weight transducer for your specific needs.

Navigating Industry Standards for Best Weight Transducer

This chart compares various weight transducer models in terms of accuracy percentage and cost. It allows for an easy evaluation of how different models stack up against each other in critical performance and affordability metrics.

Analyzing the Accuracy and Reliability Metrics of Weight Transducers

When evaluating weight transducers, accuracy and reliability are paramount metrics that cannot be overlooked. According to a recent industry report by the National Institute of Standards and Technology (NIST), precision in weight measurement can significantly impact various sectors, from pharmaceuticals to manufacturing. The report highlights that high-quality load cells can achieve an accuracy rate of up to 0.01%, making them essential for applications where even minimal errors can lead to costly repercussions.

Moreover, the reliability of weight transducers is equally critical. A reliability study published by the American Society for Testing and Materials (ASTM) indicates that the failure rate of low-quality transducers can reach up to 15% within the first year of use. This underscores the need for robust quality assurance processes during the manufacturing phase. Advanced features such as temperature compensation and digital signal processing have emerged as essential mechanisms to enhance reliability, ensuring that transducers maintain their performance under varying environmental conditions. As industries continue to evolve, selecting the right weight transducer based on these accuracy and reliability metrics will be crucial for operational success.

Exploring Common Challenges in Adhering to Weight Transducer Standards

Adhering to industry standards for weight transducers can often present a multitude of challenges for manufacturers and users alike. One of the primary obstacles is the rapid pace of technological advancements, which can render current standards obsolete almost overnight. As new materials and technologies emerge, regulators may struggle to keep up, leaving stakeholders navigating a patchwork of outdated guidelines. This discrepancy can lead to inconsistencies in product quality and reliability, complicating compliance efforts and potentially jeopardizing safety.

Furthermore, the diversity of applications for weight transducers across different industries complicates standardization efforts. Each sector—be it food and beverage, pharmaceutical, or industrial—has unique requirements and environmental conditions that affect the design and functionality of transducers. As a result, a one-size-fits-all standard can be ineffective, forcing manufacturers to create custom solutions that still align with foundational principles. This need for specialization not only increases costs but also requires a deep understanding of both the technical specifications and industry-specific regulations, creating additional hurdles for those striving to meet compliance.

Navigating Industry Standards for Best Weight Transducer and Its Challenges

| Challenge | Description | Impact on Standards | Potential Solutions |

|---|---|---|---|

| Calibration Issues | Difficulties in maintaining correct calibration over time due to environmental factors. | Can result in inaccurate weight measurements, compromising data integrity. | Regular calibration checks and using calibration weight standards. |

| Environmental Sensitivity | Weight transducers can be affected by humidity and temperature changes. | May lead to drift in readings and non-compliance with standards. | Use of environmental enclosures and controlled monitoring. |

| Material Degradation | Certain materials used in transducers may degrade over time or react with substances. | Can impact the longevity and reliability of the measurements. | Regular inspection and using durable, non-reactive materials. |

| Interference from Nearby Equipment | Electrical noise or physical interference from other equipment can affect readings. | May lead to inconsistent data and disrupt regulatory compliance. | Proper spacing and using shielding methods for equipment. |

| Data Management | Challenges in collecting, analyzing, and maintaining data integrity. | Poor data management can lead to failure in audits and inspections. | Implementing robust data management systems and regular training. |

Evaluating Cost-Benefit Analysis of Compliant vs. Non-Compliant Transducers

When evaluating weight transducers, a crucial aspect is the cost-benefit analysis of compliant versus non-compliant models. Compliant transducers often offer enhanced flexibility and adaptability, essential for applications requiring precision under varying load conditions. Their ability to accommodate different shapes and weights may justify higher upfront costs, especially in industries where accuracy directly impacts safety and performance. This characteristic is particularly important in sectors like aerospace, where every gram counts and any discrepancy in weight measurement can have significant repercussions.

On the other hand, non-compliant transducers, while potentially more affordable, may present challenges in dynamic environments. Their rigid designs could lead to inaccuracies if the application involves varying forces or environmental conditions. However, recent technological advancements, such as lightweight microsensor systems developed for real-time monitoring, highlight a shift in how compliance can be achieved without compromising performance. By integrating innovative designs and materials, industries can find a middle ground that balances cost efficiency with the reliability of compliant transducers, ultimately enhancing operational effectiveness while managing budget constraints.