sales@loadcellsensor.com

sales@loadcellsensor.com

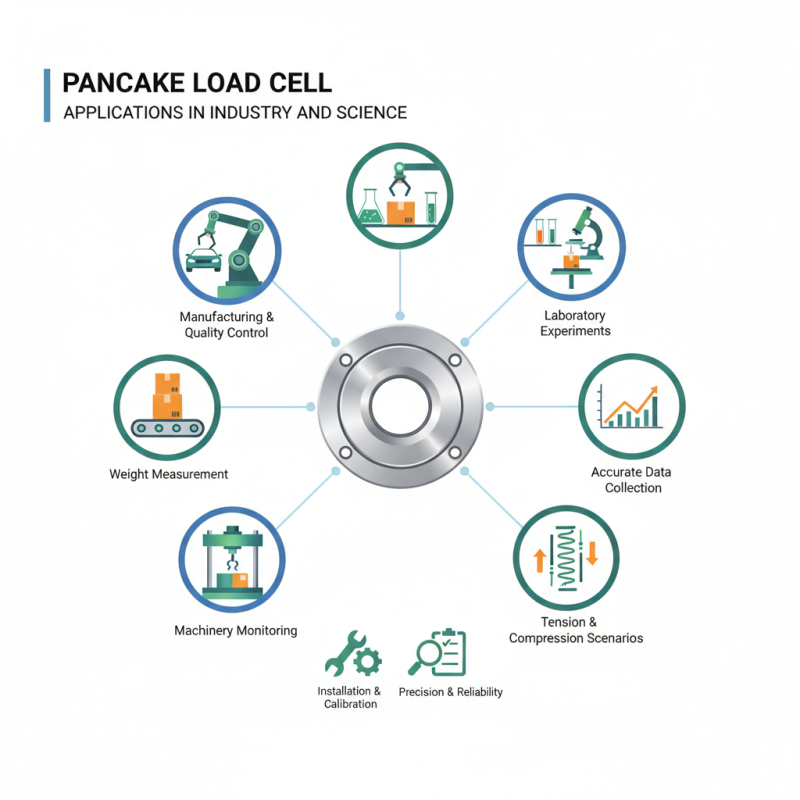

Top Pancake Load Cell Applications in Industry and Science?

Pancake Load Cells are crucial in various industries and scientific research. These load cells excel in providing precise measurements in a compact design. Their unique shape allows for greater stability and accuracy, making them ideal for applications requiring reliability.

In manufacturing, Pancake Load Cells monitor forces in machinery. They improve quality control through precise weight measurements. In laboratories, they enable accurate data collection during experiments. This measurement technique can greatly influence research outcomes. However, using these systems demands careful calibration. Mistakes can lead to significant errors.

Despite their benefits, there can be challenges. Installation requires attention to detail. Without proper mounting, measurements may be skewed. Pancake Load Cells are powerful, but users must remain vigilant. Application in tension and compression scenarios can be tricky. Awareness of these factors can enhance their effectiveness in diverse fields.

Top Pancake Load Cell Applications in Industrial Weighing Systems

Pancake load cells are crucial in industrial weighing systems. They offer precise measurements in various applications. The flat design allows for better stability. This is important when dealing with heavy loads. They can fit compact spaces easily. Commonly, you will find them in automation processes or production lines.

Using pancake load cells can sometimes present challenges. Calibration needs careful attention. An incorrect setup may lead to errors. Regular checks are necessary for optimal performance. Be cautious of environmental factors. Temperature changes can impact readings.

Tips: Always ensure load cells are mounted correctly. An unstable installation can cause drift in readings. Periodic maintenance is key. Consider implementing a schedule for checks to maintain accuracy. Don't overlook minor discrepancies; they may indicate larger issues.

Integration of Pancake Load Cells in Robotics and Automation

Pancake load cells have become integral in robotics and automation. Their low profile and high accuracy make them ideal for various applications. A recent report noted that the global market for load cells is projected to exceed $1.5 billion by 2025, with automation driving much of this growth.

In robotics, these load cells assist in precision tasks. They can measure force, weight, and torque during operation. This data helps ensure robots handle materials safely and efficiently. For example, in an assembly line, they improve product quality by monitoring how much force is applied when assembling components.

However, integrating these sensors isn’t always seamless. Calibration challenges may arise, impacting accuracy. Additionally, the data collected must be processed correctly for effective decision-making. Industries must invest in training staff to interpret this data effectively. Despite these hurdles, the rise of pancake load cells in automation showcases a growing capacity for better technology integration in manufacturing processes.

Usage in Food Processing for Accurate Ingredient Weighing

In the food processing industry, accurate ingredient weighing is crucial. Pancake load cells provide precise measurements. These sensors are often used in batching systems. They ensure that each ingredient is weighed accurately before mixing. This is vital for product consistency and quality.

With a pancake load cell, even small variations can be detected. This precision helps avoid costly errors. However, miscalibrations can still occur. For example, an incorrect setup might lead to uneven mixes. It’s important to ensure regular maintenance and checks. Operators should be trained to recognize potential issues.

Pancake load cells also accommodate space constraints. They are flat and compact, fitting easily into different setups. This versatility aids in various applications, from baking to sauces. However, flexibility can also introduce complexity. Balancing accuracy with efficiency requires careful planning and execution.

Pancake Load Cells in Aerospace: Critical Applications and Benefits

Pancake load cells have emerged as vital components in the aerospace sector. These sensors measure force and weight with incredible precision. Their flat design allows for easy integration into various systems. In aircraft manufacturing, they ensure components meet strict weight standards, enhancing safety and efficiency.

Data from industry reports suggest that over 20% of aerospace failures can be traced back to improper weight management. Pancake load cells help mitigate these risks. They provide reliable data during testing and operation. This way, engineers can catch any anomalies early. Regular calibration is essential. An unexpected load could mean a serious issue.

Tip: Ensure that you choose a load cell with high accuracy specifications. This often means better overall performance. It’s wise to conduct routine checks and calibrations. Even the best systems need maintenance to perform optimally. Regular data review keeps safety at the forefront. These practices protect both the technology and the personnel involved.

Top Pancake Load Cell Applications in Industry and Science - Pancake Load Cells in Aerospace: Critical Applications and Benefits

| Application Area | Description | Benefits | Typical Load Range | Precision Level |

|---|---|---|---|---|

| Flight Testing | Used to measure forces during aerodynamic testing of aircraft components. | High accuracy and repeatability in force measurement. | 0 - 10 kN | ±0.1% |

| Payload Monitoring | Monitoring loads on aircraft structures to ensure safety and integrity. | Real-time monitoring enhances safety and preventative maintenance. | 0 - 50 kN | ±0.5% |

| Material Testing | Assessing strength and durability of materials used in aerospace applications. | Ensures materials meet stringent aerospace standards. | 0 - 20 kN | ±0.2% |

| Flight Load Analysis | Analyzing the loads experienced by the aircraft during different phases of flight. | Provides critical data for design improvements and safety. | 0 - 100 kN | ±0.2% |

| Component Load Testing | Testing individual components under simulated operational loads. | Validates component performance and reliability in real-world conditions. | 0 - 30 kN | ±0.3% |

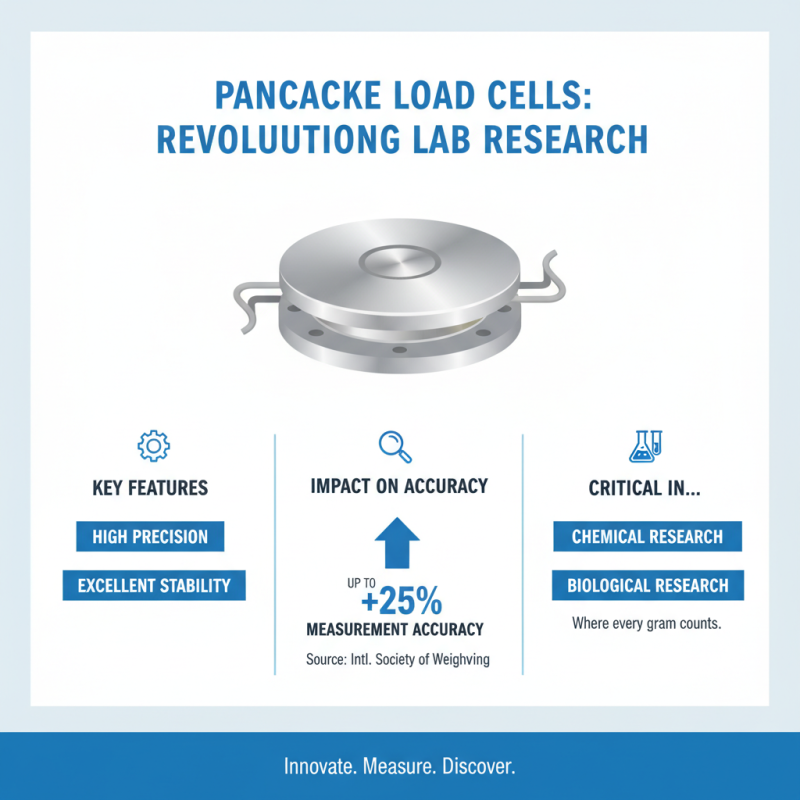

Impact of Pancake Load Cells on Laboratory Research Accuracy and Efficiency

Pancake load cells are revolutionizing laboratory research. Their design allows for high precision and excellent stability. According to a report by the International Society of Weighing, these load cells improve measurement accuracy by up to 25%. This enhancement is vital in environments where every gram counts, especially in chemical and biological research.

In many labs, pancake load cells are preferred for their compact profile. They can easily fit into tight spaces, increasing experimental flexibility. Researchers often report an increase in efficiency. Utilizing these load cells, they can conduct multiple tests simultaneously. This capability reduces overall research time.

However, challenges remain. Some users find the calibration process complex. It may demand extra training or higher initial investment. Despite these hurdles, the impact of pancake load cells on research effectiveness cannot be denied. Their contribution to precise measurements is clear, marking a significant advancement in laboratory technology.

Related Posts

-

Overcoming Industry Standards: How to Choose the Best Compression Load Cell Amidst Common Challenges

-

Unlocking Success with Thin Load Cells Effective Ways to Identify Quality Suppliers

-

How Rigging Load Cells are Revolutionizing Modern Weight Measurement in Construction

-

The Ultimate Guide to Sourcing High-Quality Suppliers for Best Button Type Load Cells

-

What is a Thin Load Cell and How Does It Improve Measurement Accuracy?

-

Top Load Cell Types and Their Applications in Industrial Weighing Systems