sales@loadcellsensor.com

sales@loadcellsensor.com

Understanding the Science Behind Torque Load Cells: Applications and Innovations

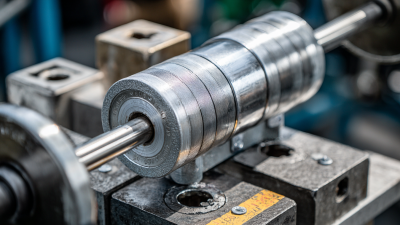

In the realm of force measurement technology, torque load cells stand out as critical instruments that facilitate accurate and reliable assessments of torque in various applications. These devices operate on the principle of converting the mechanical force exerted by a rotating object into an electrical signal, enabling precise quantification of torque levels. The importance of torque load cells spans across multiple industries, from automotive engineering to aerospace, where they play a pivotal role in quality control, testing, and research and development. Innovations in torque load cell design, such as enhanced sensitivity and miniaturization, have further propelled their utility, allowing for more straightforward integration into complex systems and devices. This article delves into the science behind torque load cells, exploring their fundamental principles, diverse applications, and the latest technological advancements that continue to shape their evolution in modern engineering practices.

Exploring the Fundamental Principles of Torque Load Cells in Modern Applications

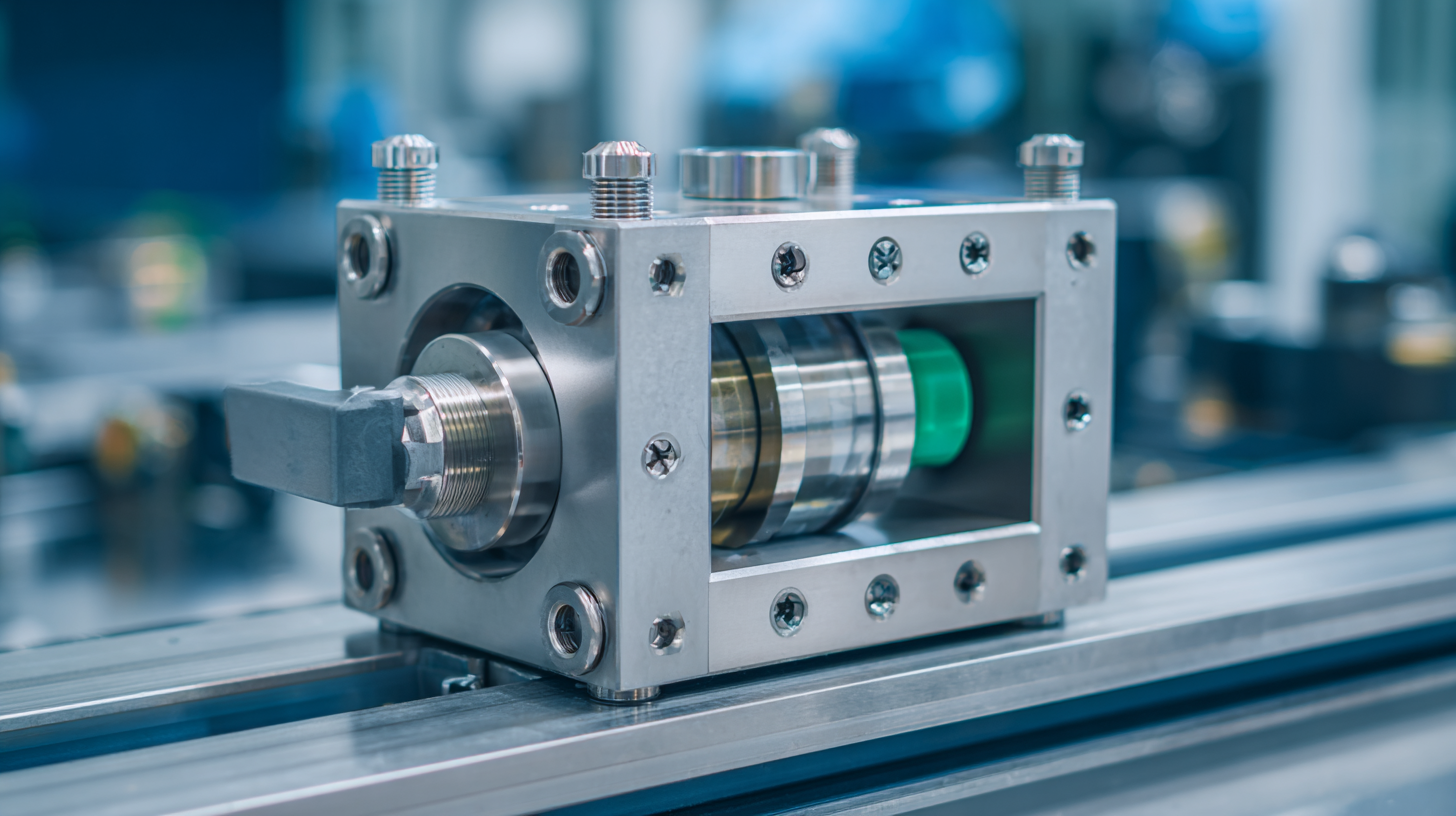

Torque load cells are essential devices that measure rotational force, highlighting their fundamental principles in various modern applications. These sensors operate on the principle of converting mechanical torque into an electrical signal, usually through the deformation of a strain gauge. The accurate measurement of torque is crucial in industries such as automotive, aerospace, and manufacturing, where precise engineering and quality control are paramount.

When implementing torque load cells, keep in mind a few tips to ensure optimal performance. First, always consider the installation position and orientation of the load cell, as misalignment can lead to inaccurate readings. Second, regular calibration is vital to maintain accuracy over time, especially in environments with fluctuating conditions. Additionally, choose a load cell with suitable sensitivity and range for your specific application to ensure reliable data collection.

Innovations in torque load cell technology, such as wireless communication and advanced data analytics, are enhancing their functionality and usability. These advancements allow for real-time monitoring and remote access to data, increasing efficiency and improving decision-making processes in various fields. As industries continue to evolve, understanding the application of torque load cells will undoubtedly play a significant role in driving progress and innovation.

Innovative Techniques for Measuring Torque: Advancements in Load Cell Technology

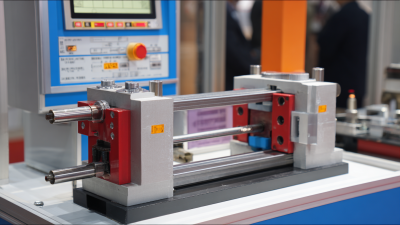

Innovative techniques for measuring torque have evolved significantly with advancements in load cell technology. Torque load cells are now equipped with high-precision sensors that facilitate real-time data collection, enabling engineers and technicians to monitor torque in various applications, from automotive manufacturing to aerospace engineering. These advancements allow for greater accuracy and reliability, which are crucial in maintaining safety standards and enhancing operational efficiency.

Recent innovations include the integration of wireless technology with torque load cells, providing seamless data transfer and remote monitoring capabilities. This development not only reduces the need for physical connections but also enhances mobility in testing applications. Additionally, the implementation of smart algorithms and artificial intelligence in data analysis offers deeper insights into torque patterns, helping in predictive maintenance and reducing the risk of equipment failures. As these technologies continue to evolve, the potential for torque load cells to improve industrial processes and product quality remains immense.

Understanding the Science Behind Torque Load Cells: Applications and Innovations

This bar chart illustrates the various applications of torque load cells across different industries, showcasing the torque measurement values in Newton-meters (Nm). Each sector demonstrates unique torque requirements, highlighting the innovative techniques applied in load cell technology.

Key Industrial Applications of Torque Load Cells Across Various Sectors

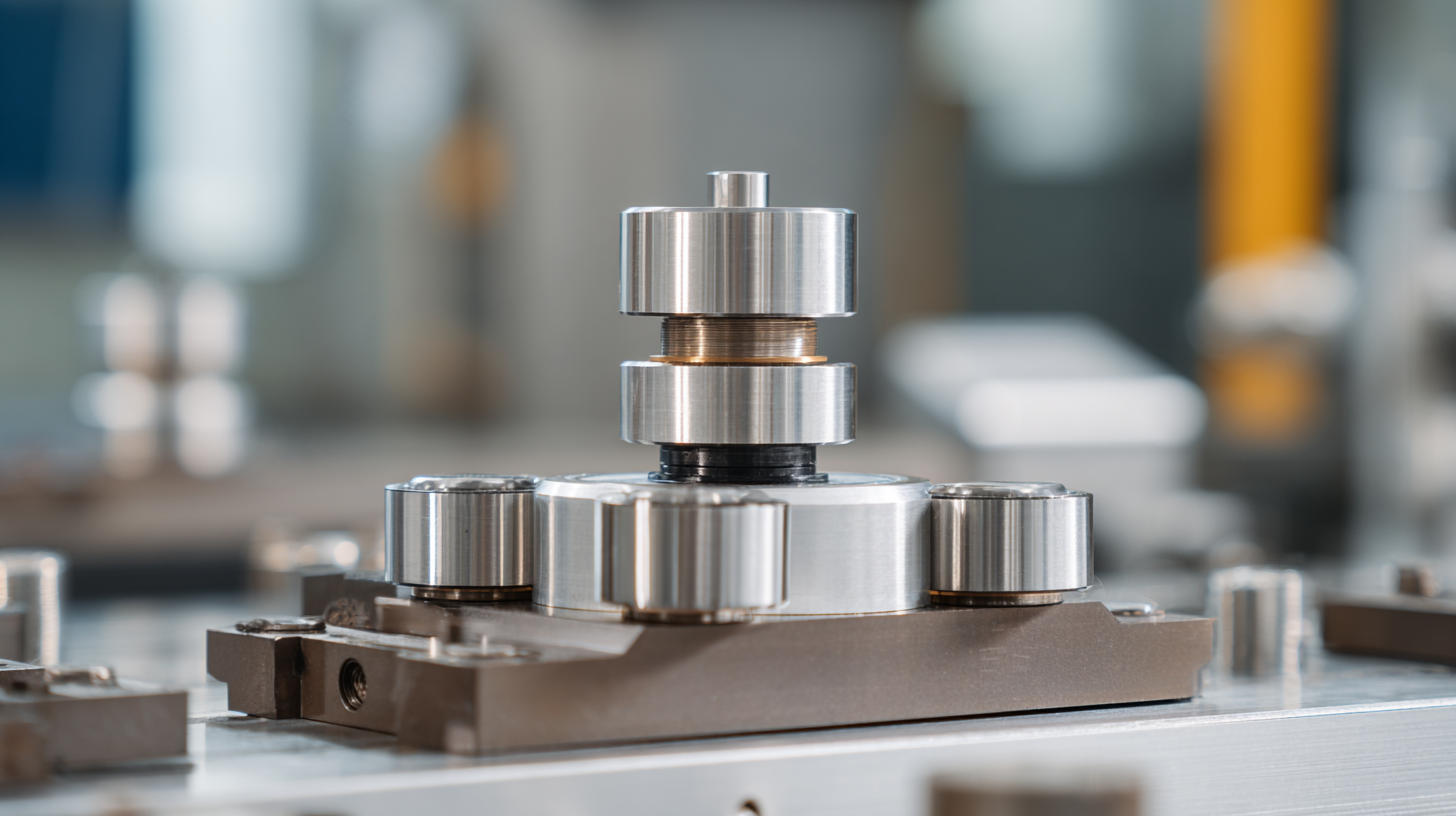

Torque load cells are instrumental in a wide array of industrial sectors, enhancing efficiency and precision in torque measurement and monitoring. In the automotive industry, these load cells are often used in testing scenarios, such as evaluating the performance of engines and ensuring that assembly processes maintain the correct torque specifications. By providing accurate feedback, torque load cells help prevent over-tightening or under-tightening, leading to improved safety and reliability of vehicles.

Torque load cells are instrumental in a wide array of industrial sectors, enhancing efficiency and precision in torque measurement and monitoring. In the automotive industry, these load cells are often used in testing scenarios, such as evaluating the performance of engines and ensuring that assembly processes maintain the correct torque specifications. By providing accurate feedback, torque load cells help prevent over-tightening or under-tightening, leading to improved safety and reliability of vehicles.

In the aerospace sector, where precision is paramount, torque load cells aid in the assembly of critical components, ensuring that fasteners are tightened to exact specifications. This is crucial for the integrity of aircraft structures and systems, as even minor variations can lead to significant safety concerns. Furthermore, in the manufacturing and process industries, torque load cells are integrated into automated systems for conveyor belts, packaging, and various machinery, enabling real-time monitoring and adjustments to optimize operations. The innovations in torque load cell technology continue to expand their applications, reinforcing their importance across these diverse industries.

The Role of Digital Technology in Enhancing Torque Load Cell Performance

The emergence of digital technology has significantly transformed the performance of torque load cells, enhancing their precision and functionality across various applications. By integrating advanced digital signal processing techniques, modern torque load cells can offer real-time data transmission and improved accuracy. The incorporation of microprocessors allows for complex algorithms to analyze torque measurements instantly, providing users with highly reliable data that can be utilized for monitoring and control in industrial settings.

Additionally, digital technology has facilitated the development of user-friendly interfaces and cloud connectivity for torque load cells. This allows operators to easily access and manage data remotely, ensuring that critical parameters are consistently monitored. Moreover, innovations like wireless communication have enabled torque load cells to be integrated into automated systems, improving workflow efficiency and minimizing human error. The combination of these advancements paves the way for smarter applications in fields such as manufacturing, automotive, and aerospace, where precision and reliability are paramount.

Future Trends in Torque Load Cells: Innovations Shaping the Industry Landscape

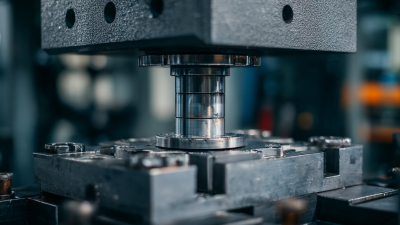

The torque load cell industry is experiencing significant advancements as technology evolves. Innovations are not only enhancing the accuracy of torque measurements but also improving the versatility of these devices across various applications. For instance, the integration of IoT capabilities allows real-time data monitoring and analysis, enabling engineers to optimize performance and troubleshoot issues effectively. As industries increasingly rely on automation and data-driven insights, we can anticipate a surge in demand for smart torque load cells that provide advanced analytics and connectivity features.

Tip: When selecting a torque load cell, consider its compatibility with existing systems and the extent of its data reporting capabilities. This foresight can save time and resources during implementation, ensuring that you choose a solution that aligns with future technological developments.

Another trend shaping the torque load cell landscape is the miniaturization of devices. As industries lean towards compact designs, manufacturers are developing smaller, lighter load cells without compromising performance. This shift opens new avenues in automotive and aerospace sectors, where space is at a premium.

Tip: Always assess the environmental conditions in which the load cell will operate. The right choice can enhance durability and accuracy, making your investment more sustainable in the long run.

Understanding the Science Behind Torque Load Cells: Applications and Innovations - Future Trends in Torque Load Cells: Innovations Shaping the Industry Landscape

| Dimension | Description | Current Application | Future Trends |

|---|---|---|---|

| Accuracy | Precision levels in measurement | Industrial machinery monitoring | Advanced algorithms for real-time data analysis |

| Load Capacity | Maximum load cell capacity | Torque testing in automotive applications | Lighter materials and higher capacities |

| Response Time | Time taken to measure changes | Dynamic torque applications | Instantaneous feedback mechanisms |

| Size & Integration | Physical dimensions affecting placement | Compact designs in robotics | Miniaturization and IoT integration |

| Cost Efficiency | Price-performance ratio analysis | Sensory overload in manufacturing processes | Affordable smart torque solutions |

Related Posts

-

Unlocking Industry Potential with Strain Gauge Load Cells at the 2025 China Import and Export Fair

-

How to Maximize Efficiency in Your Operations with Bending Beam Load Cells

-

The Ultimate Guide to Choosing the Best Load Cell for Your Needs

-

Common Issues Faced When Using Best Small Load Cells

-

Ultimate Checklist for Choosing the Best Compression Type Load Cell for Your Business Needs

-

Exploring the Future of Load Cells: Innovations Beyond the Best Bending Beam by 2025