sales@loadcellsensor.com

sales@loadcellsensor.com

How to Select the Right Torque Sensor for Enhanced Precision in Industrial Applications

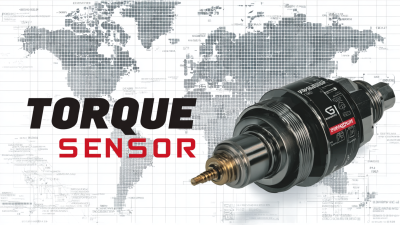

In modern industrial applications, the precision of mechanical systems is paramount, and selecting the right Torque Sensor is crucial for achieving optimal performance. According to a report by MarketsandMarkets, the torque sensor market is projected to grow from USD 421 million in 2020 to USD 595 million by 2025, with a compound annual growth rate (CAGR) of 7.1%. This growth is driven by the increasing demand for automation and the need for high-accuracy measurements in various sectors, including automotive, aerospace, and manufacturing. A Torque Sensor not only measures the torque applied to a rotating object but also provides essential feedback for system monitoring and preventive maintenance.

With a multitude of options available in the market, understanding the specific requirements of your industrial application is vital to select a Torque Sensor that enhances operational efficiency, accuracy, and reliability.

Understanding Torque Sensor Types and Their Applications

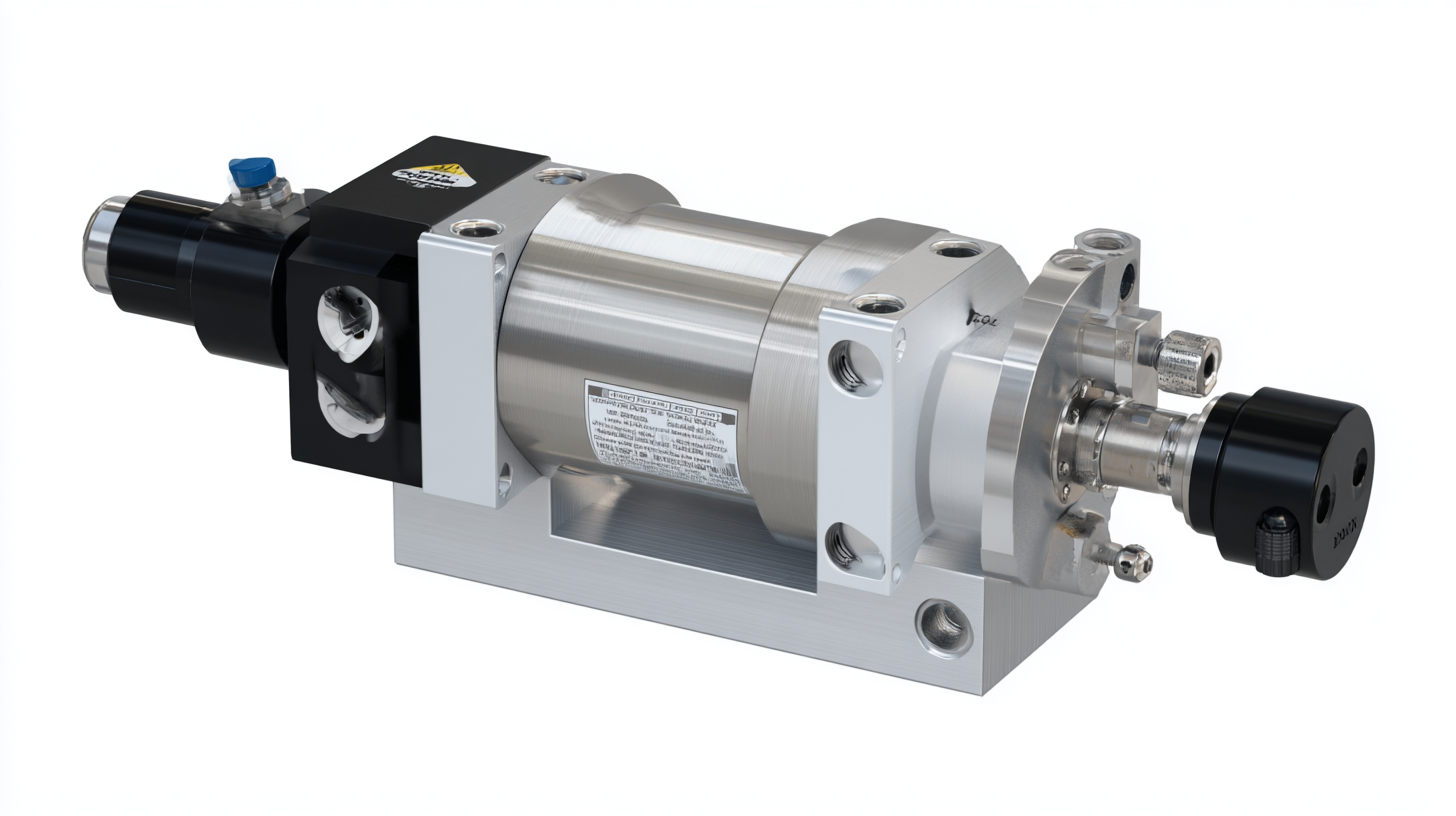

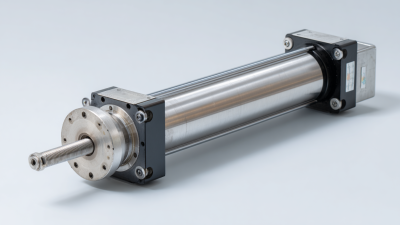

When selecting a torque sensor for industrial applications, it’s essential to understand the different types of sensors available and their specific applications. The most common types include strain gauge sensors, rotary torque sensors, and reaction torque sensors. Strain gauge sensors are often used for static measurements and provide high precision, making them ideal for testing and calibration in labs. In contrast, rotary torque sensors are designed for dynamic measurements, perfect for monitoring torque in rotating machinery such as motors and turbines.

Tips: When choosing a torque sensor, consider the measurement range and resolution required for your application. Ensure the sensor can handle the maximum torque expected during operation without sacrificing accuracy.

Another key aspect is the environment in which the sensor will be used. For instance, sensors designed with robust casings can withstand harsh operating environments, including extreme temperatures and vibrations. Reaction torque sensors are typically employed in applications like assembly lines, where a quick response time and durability are crucial for maintaining efficiency.

Tips: Always check for compatibility with your existing machinery and consider the ease of integration. Engaging with the sensor manufacturer for specific application guidelines can significantly enhance the selection process.

Key Factors to Consider When Choosing a Torque Sensor

When selecting a torque sensor for industrial applications, several key factors must be considered to ensure enhanced precision and reliability. First, it’s essential to evaluate the sensor’s range and accuracy. Industrial settings often involve varying torque levels, so a sensor with a wide measurement range and high resolution will be more versatile and effective. Furthermore, the accuracy specifications should align with the operational requirements to maintain quality control and minimize errors in manufacturing processes.

Another crucial aspect is the sensor's durability and environmental resistance. Industrial applications can expose sensors to harsh conditions such as extreme temperatures, humidity, and mechanical vibrations. Therefore, choosing a torque sensor that is designed to withstand these factors is vital for long-term performance. Additionally, the type of output signal (analog vs. digital) and the compatibility with existing systems should be assessed to ensure seamless integration. By carefully considering these factors, industries can enhance their operational precision and efficiency through the right choice of torque sensors.

Evaluating Precision Requirements for Industrial Use Cases

Selecting the right torque sensor requires a thorough evaluation of the precision requirements specific to your industrial application. Different use cases demand varying levels of accuracy, which can significantly impact performance and product quality. For instance, in applications where precise torque measurement is crucial, such as in assembly processes of critical components, a high-resolution torque sensor is essential. On the other hand, less sensitive applications may allow for more tolerance, enabling the use of more cost-effective options.

Tips:

1. Assess Your Application's Sensitivity: Understand the level of precision needed based on the operational environment and the consequences of potential discrepancies.

2. Consider Environmental Factors: Evaluate how temperature, humidity, and vibrations may impact sensor performance, and select a sensor that can withstand these conditions.

3. Compatibility with Existing Systems: Ensure that the selected torque sensor can seamlessly integrate with your existing data acquisition systems for optimal performance.

By focusing on these evaluation criteria, you can make an informed decision that enhances precision and reliability in your industrial applications.

Integration Considerations for Torque Sensors in Existing Systems

When integrating torque sensors into existing systems, several factors must be considered to ensure optimal performance and accuracy. The first aspect to evaluate is the compatibility of the torque sensor with the current machinery. According to a report by MarketsandMarkets, torque sensors are expected to grow at a CAGR of 6.8% from 2020 to 2025, highlighting the increasing need for efficient integration in industrial settings. Choosing a sensor that aligns with the system’s operational limits, including range, sensitivity, and environmental conditions, is crucial for achieving desired precision levels.

Tips: Always assess the mounting requirements of the torque sensor, as improper installation can lead to misalignment and inaccurate readings. Additionally, consider the data acquisition systems already in place, ensuring that the output signals from the sensor are compatible with existing interfaces.

Another key consideration is the calibration process. A study from the International Journal of Advanced Manufacturing Technology emphasizes that accurate calibration is essential for maintaining the integrity of torque measurements. Regular calibration intervals should be established based on usage patterns to adapt to wear and potential drift in measurement accuracy. Engaging with suppliers that offer support for both installation and calibration can greatly enhance the integration experience and ensure long-term reliability.

Torque Sensor Performance in Industrial Applications

Maintenance and Calibration Tips for Long-lasting Accuracy

Regular maintenance and calibration of torque sensors are crucial for ensuring long-lasting accuracy in industrial applications. To maintain optimal performance, it is essential to establish a routine inspection schedule. This should include checking for physical wear and damage, such as loose connections or worn components, which can compromise accuracy. Additionally, dust and debris can accumulate on sensors, affecting their functionality, so keeping them clean is paramount. Implementing a cleaning protocol that adheres to the manufacturer’s recommendations can greatly prolong the life of the sensor and maintain its precision.

Calibration is another critical component in preserving the accuracy of torque sensors. It involves comparing the sensor's output to a known standard and adjusting it as necessary to ensure precise readings. Regular intervals for recalibration should be determined based on the specific application and level of use; high-demand environments may require more frequent checks. Moreover, employing automated calibration systems can streamline the process, minimizing human error and providing consistent results. By prioritizing maintenance and calibration, industries can achieve enhanced precision and reliability from their torque sensors, ultimately leading to improved operational efficiencies.

How to Select the Right Torque Sensor for Enhanced Precision in Industrial Applications - Maintenance and Calibration Tips for Long-lasting Accuracy

| Sensor Type | Application | Capacity (Nm) | Accuracy (%) | Calibration Frequency (months) |

|---|---|---|---|---|

| Strain Gauge | Automotive Assembly | 0-100 | 0.5 | 12 |

| Rotational Torque | Manufacturing | 0-200 | 1.0 | 6 |

| Reaction Torque | Quality Control | 0-500 | 0.8 | 12 |

| Digital Torque | Research and Development | 0-50 | 0.2 | 24 |

| Mechanical Torque | Heavy Machinery | 0-1000 | 1.5 | 12 |

Related Posts

-

Unleashing China's Manufacturing Excellence: A Deep Dive into the Best Torque Sensor Innovations

-

Navigating the Global Standards for Best Torque Sensor Imports and Exports

-

Maximizing Precision: Key Techniques for Effective Torque Sensor Implementation

-

Understanding the Basics of Torque Sensor Functionality and Applications

-

Revolutionizing Measurements An Insight into the 2025 Trends for Best Rotary Torque Transducers

-

Exploring Innovative Torque Sensor Types: Real-World Applications and Benefits