sales@loadcellsensor.com

sales@loadcellsensor.com

Understanding the Importance of Shaft Torque Sensors in Modern Engineering Practices

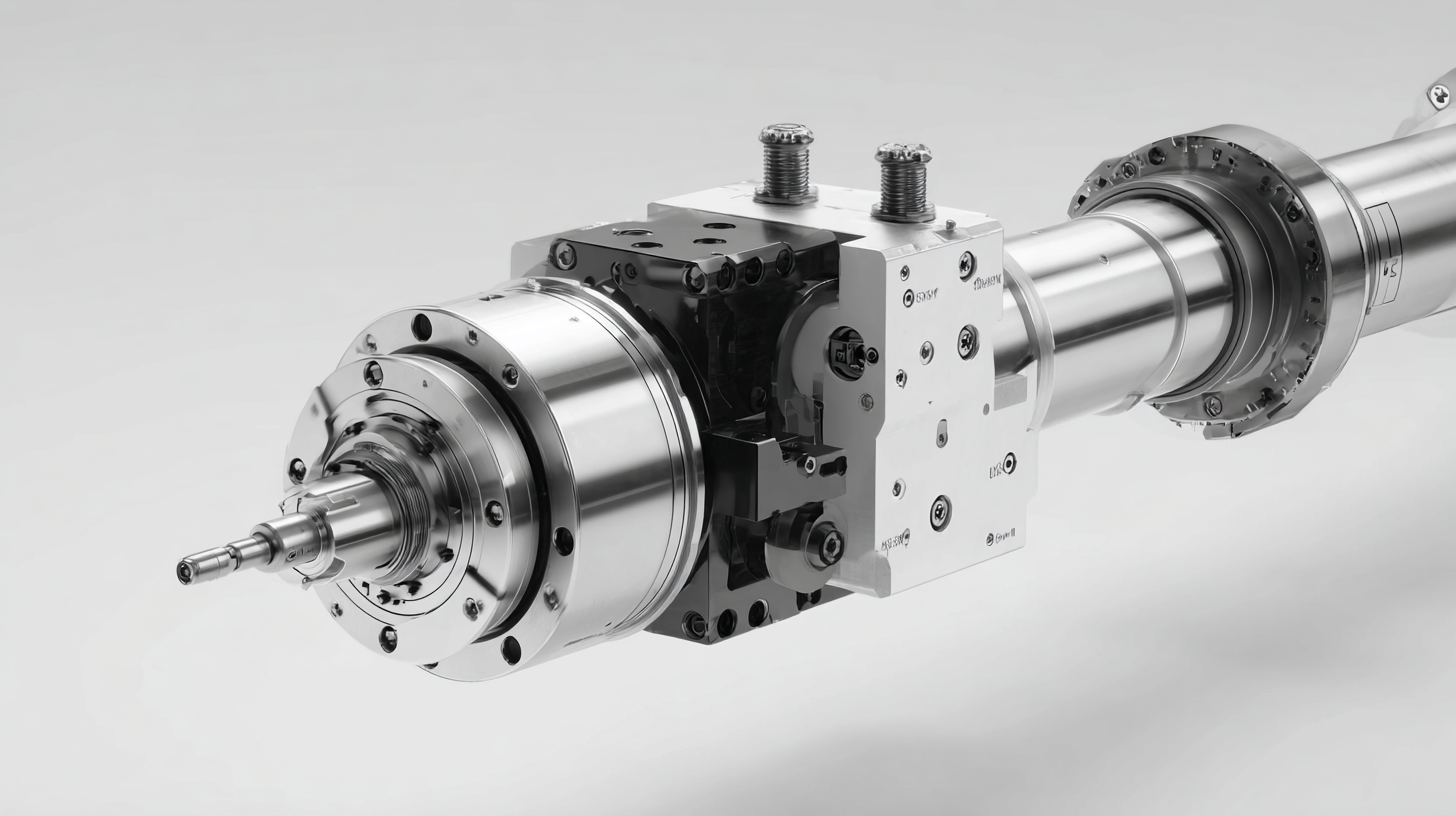

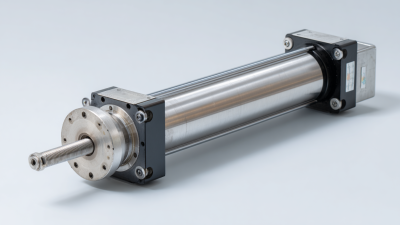

In contemporary engineering practices, the significance of precise measurements cannot be overstated, particularly when it comes to the performance and efficiency of machinery. One critical component that plays a pivotal role in this area is the Shaft Torque Sensor. By accurately measuring the torque transmitted through a shaft, these sensors enable engineers to monitor and optimize the performance of various systems, from automotive applications to industrial machinery.

The ability to gather real-time data on torque not only aids in diagnosing potential issues before they escalate into costly repairs but also enhances the overall safety and reliability of mechanical operations. As industries increasingly adopt automation and smart technologies, the relevance of Shaft Torque Sensors becomes even more pronounced, marking them as essential tools in the pursuit of innovation and operational excellence.

Understanding the importance of these sensors paves the way for advancements in both engineering design and application, ultimately leading to improved productivity and sustainability in modern engineering practices.

How to Identify the Right Shaft Torque Sensor for Your Application

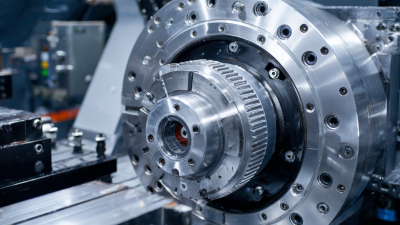

In the realm of modern engineering practices, selecting the appropriate shaft torque sensor for specific applications is crucial, as it can significantly impact performance and efficiency. With the increasing demand for precision in various industries—most notably in robotics—the marketplace is seeing a surge in innovative torque sensor technologies. Recent reports indicate that multi-axis force sensors and joint torque sensors are gaining traction, particularly in humanoid robotics, which underscores the necessity for advanced torque measurement capabilities.

When identifying the right shaft torque sensor, engineers must consider key factors such as the sensor's range, sensitivity, and compatibility with existing systems. For instance, high-precision torque sensors, such as those capable of measuring up to 50 Nm or more, have become essential in applications ranging from automotive manufacturing to robotics. Moreover, the emerging trend of integrating intelligent torque adaptation systems highlights the value of real-time data in optimizing operational performance, showcasing how sophisticated sensor technologies can enhance overall system responsiveness and accuracy. As the competition intensifies in the force sensor market, understanding these nuances is vital for making informed decisions that align with project requirements.

How to Install Shaft Torque Sensors for Optimal Performance

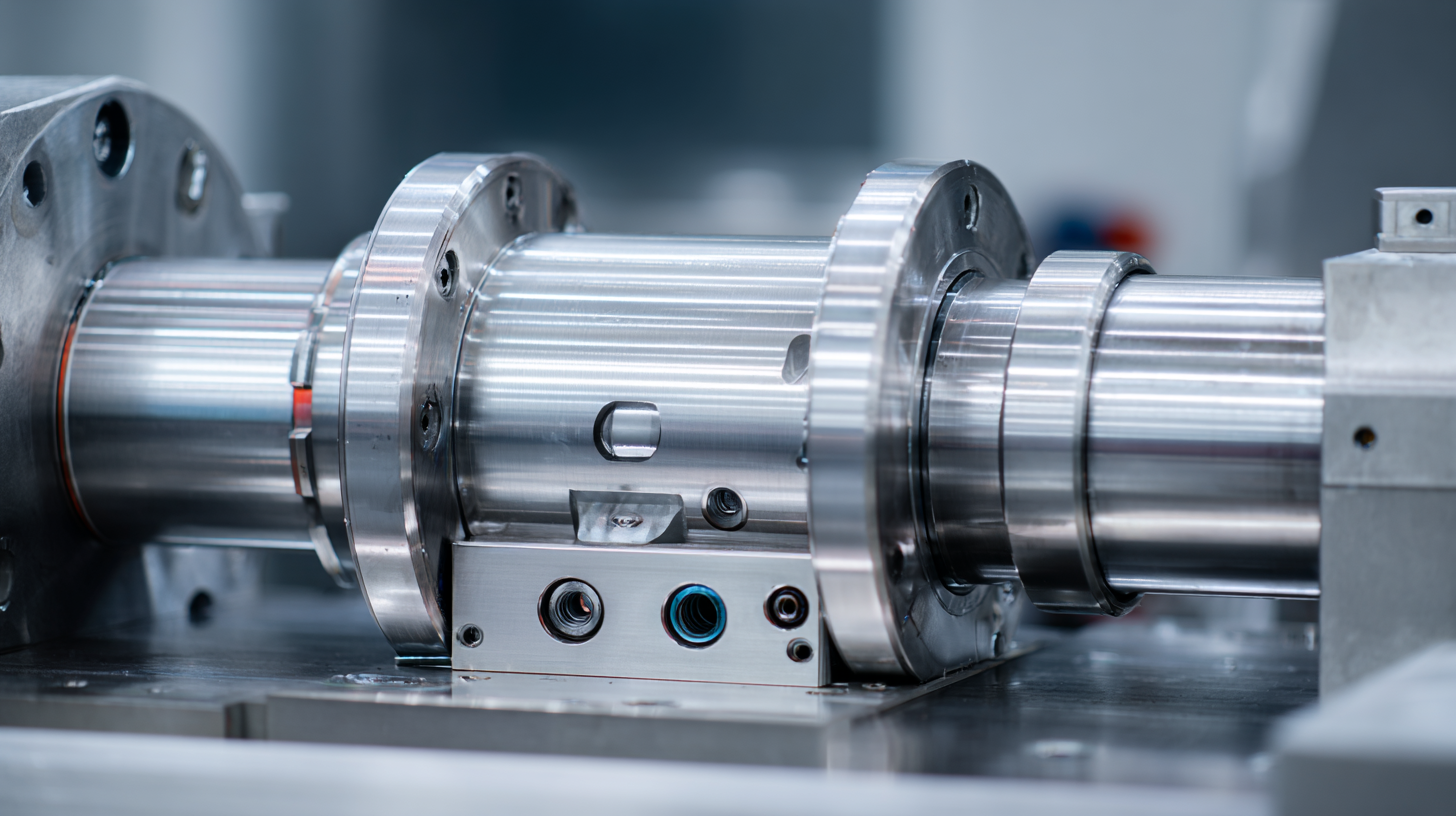

Shaft torque sensors play a crucial role in modern engineering practices, particularly in enhancing the performance of robotic systems. Installing these sensors correctly is essential for optimal functionality. When positioning shaft torque sensors, it is crucial to ensure they are aligned properly with the shaft to accurately capture torque measurements. According to industry reports, the demand for precise torque measurements has surged, especially in applications involving collaborative robots, which require sensitive feedback to optimize their interactions with human operators.

To install shaft torque sensors effectively, consider these tips: First, ensure that the sensor is securely mounted on a sturdy surface to prevent any vibrations that can lead to inaccuracies in measurement. Second, use the appropriate torque settings specified by the manufacturer for mounting, ensuring a tight fit without over-tightening. Lastly, connect the sensor to a reliable data acquisition system to monitor the readings accurately and make real-time adjustments as needed.

As robotics and automation technologies evolve, the integration of torque sensors becomes increasingly significant. For example, the emerging market for six-dimensional force sensors highlights the necessity for real-time feedback and control in robotic operations, emphasizing that proper installation and calibration of shaft torque sensors are vital to achieving desired performance levels and preventing potential system failures.

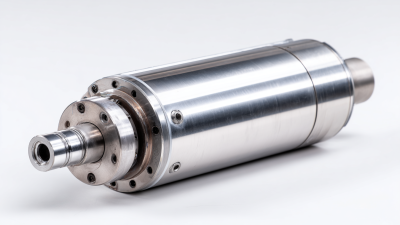

How to Calibrate and Maintain Shaft Torque Sensors Effectively

Calibrating and maintaining shaft torque sensors is essential for ensuring accurate measurements and reliable performance in modern engineering practices. Proper calibration involves adjusting the sensor's output to reflect its true performance under specific conditions. This process typically includes defining the operational parameters, performing reference measurements, and applying adjustments as needed. Regular recalibration, especially after significant workload changes or sensor replacements, is vital to maintain precision.

Tip: Always document the calibration date and results in a maintenance log to keep track of when recalibration is due. This practice not only helps in maintaining accuracy but also aids in compliance with industry standards.

Maintenance is equally crucial for extending the lifespan of shaft torque sensors. Regular inspections for wear or damage, along with ensuring proper installation, can prevent costly failures. It’s important to clean the sensors routinely, keeping them free from contaminants that could affect performance.

Tip: Create a maintenance schedule that includes routine inspections, cleaning, and testing to ensure your sensors are operating optimally. This proactive approach significantly reduces downtime and enhances overall productivity.

How to Interpret Data from Shaft Torque Sensors in Engineering Projects

Interpreting data from shaft torque sensors is crucial in modern engineering projects, as these sensors provide real-time insights into the performance and efficiency of mechanical systems. The data collected includes torque values, which can be analyzed to assess the load conditions under which a machine operates. Engineers can utilize this information to optimize design parameters, thereby enhancing the reliability and longevity of components. The ability to pinpoint abnormal torque fluctuations can also help diagnose potential issues early in the machinery's lifecycle.

Moreover, effective data interpretation involves correlating the torque readings with other performance metrics, such as speed and power output. This integration allows engineers to establish a comprehensive understanding of the operational efficiency of a system. For example, by analyzing torque data during varying load conditions, engineers can identify peak performance zones and determine the ideal operational range, ultimately leading to better decision-making in design and maintenance strategies. Engaging with this data not only aids in improving current designs but also informs future engineering innovations, showcasing the indispensable role of shaft torque sensors in enhancing modern engineering practices.

How to Integrate Shaft Torque Sensors into Existing Systems for Improved Control

The integration of shaft torque sensors into existing systems is gaining traction in modern engineering practices, as their role in improving control and performance is increasingly recognized. These sensors offer real-time data, allowing for precisely tuned responses in various applications. For instance, in systems such as electric drives or robotics, utilizing advanced control strategies like Adaptive Sliding Mode Control can significantly mitigate torque ripple, enhancing overall system efficiency. By coupling torque sensors with intelligent controllers, engineers can achieve a more responsive and adaptive system that meets the demands of higher performance and reliability.

In automotive applications, the deployment of contactless torque sensing technology is revolutionizing steering mechanisms. By accurately measuring both angular position and applied torque, these sensors facilitate improved vehicle dynamics and safety. The integration process involves aligning the sensors with existing electronic systems, ensuring seamless communication and feedback loops. These advancements underscore the importance of shaft torque sensors, not only in enhancing existing technologies but also in paving the way for innovative designs, such as automated assembly systems for complex machinery. As the field continues to evolve, the potential applications and benefits of integrating these sensors are poised to expand, driving further advancements in engineering practices.

Torque Measurement in Modern Engineering Practices

Related Posts

-

Understanding the Basics of Torque Sensor Functionality and Applications

-

Exploring Innovative Torque Sensor Types: Real-World Applications and Benefits

-

Precision Engineering: Chinese Manufacturing Innovating Global Torque Transducer Solutions

-

How to Select the Best Rotary Torque Transducer for Your Industrial Needs

-

Revolutionizing Measurements An Insight into the 2025 Trends for Best Rotary Torque Transducers

-

Maximizing Precision: Key Techniques for Effective Torque Sensor Implementation