sales@loadcellsensor.com

sales@loadcellsensor.com

Top Strategies for Enhancing Accuracy with Miniature Load Cells

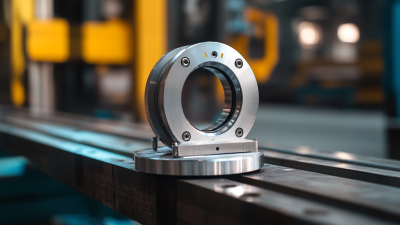

In the realm of precision measurement, Miniature Load Cells have emerged as essential components for various applications ranging from medical devices to aerospace engineering. The benefits of integrating these compact sensors into your systems are manifold, not only enhancing accuracy but also improving reliability and efficiency. As industries demand more advanced solutions, the need to optimize the performance of Miniature Load Cells becomes critical. This blog will delve into top strategies for enhancing the accuracy of these sensors, exploring innovative techniques and best practices that can help you achieve superior measurement outcomes. By implementing these strategies, you can unlock the full potential of Miniature Load Cells, ensuring that your projects meet the highest standards of performance and precision.

Best Practices for Choosing the Right Miniature Load Cell for Your Project

When selecting the right miniature load cell for your project, several factors can significantly enhance measurement accuracy. First, it's essential to consider the load cell's design and its sensitivity. According to a report by the National Institute of Standards and Technology (NIST), choosing a load cell with a high sensitivity rating can improve accuracy by up to 20% in certain applications. This is particularly vital in sectors such as aerospace and automotive testing, where minute measurements can lead to substantial differences in performance assessments.

Another crucial element is the calibration of the miniature load cell. The International Society of Automation (ISA) emphasizes the importance of regular calibration, stating that cells should be calibrated at least once a year to maintain their accuracy within 0.1% of the full scale. Additionally, environmental conditions play a significant role in the performance of load cells. A study published in the Journal of Mechanical Engineering found that temperature variations could cause drift in measurements, highlighting the need for temperature compensation features in the chosen load cell. By prioritizing these best practices, engineers can ensure that they achieve optimal results in their projects, maximizing both reliability and performance.

Understanding the Importance of Calibration for Accurate Measurements

Calibration is a critical aspect of ensuring the accuracy of measurements taken with miniature load cells. According to research, effective calibration methods significantly enhance the reliability of data gathered from these precision instruments. For instance, in the field of seismic analysis, studies have evaluated calibration methods that utilize realistic loading histories, which outperform traditional incremental cyclic loading approaches. Such insights underline the necessity of employing advanced calibration techniques to maintain measurement integrity, particularly in demanding environments.

Furthermore, calibration plays a pivotal role across various sectors, including healthcare, where accurate measurements are paramount. Recent discussions highlighted how proper calibration in healthcare ensures precision in diagnostics and treatment, emphasizing that reliable care starts with accurate medical measurements. This is not only important for industrial applications but also for ensuring optimal performance in laboratory settings, such as with analytical balances. Ensuring that these balances are accurately calibrated allows for minimal systematic errors, which is crucial as even slight discrepancies can lead to significant data inaccuracies. Thus, understanding and implementing robust calibration strategies remains essential for enhancing the accuracy of measurements with miniature load cells.

Top Strategies for Enhancing Accuracy with Miniature Load Cells

This chart illustrates the accuracy improvement in measurements of miniature load cells through various calibration techniques. Data shows the percentage accuracy achieved through five different calibration methods.

Tips for Minimizing Environmental Influences on Load Cell Performance

To enhance the accuracy of miniature load cells, it is essential to consider environmental influences that can affect their performance. Factors such as temperature fluctuations, humidity, and electromagnetic interference can significantly impact measurement precision. Therefore, creating a controlled environment for load cell operation is crucial.

One effective tip is to use environmental enclosures that shield the load cells from dust, moisture, and temperature variations. This can help maintain consistent conditions and ensure reliable performance. Additionally, regular calibration can mitigate the effects of environmental changes, aligning the load cell readings with standard measurements.

Another strategy involves the selection of appropriate materials and coatings that enhance the load cell's durability against environmental stressors. For instance, employing corrosion-resistant materials can prolong the lifespan of the load cell, especially in harsh settings. Furthermore, integrating IoT-enabled smart sensors can facilitate real-time monitoring, allowing for immediate adjustments to counteract any adverse environmental impacts, thereby optimizing load cell accuracy.

Common Installation Mistakes to Avoid for Improved Accuracy

When it comes to maximizing the accuracy of miniature load cells, avoiding common installation mistakes is crucial. One of the most prevalent errors is neglecting the proper mounting surface. It’s essential to ensure that the load cell is installed on a stable and level platform. An uneven surface can introduce significant measurement errors, affecting the load cell's performance.

Another critical tip is to pay attention to environmental factors. Excessive temperature fluctuations and humidity can impact the load cell’s accuracy. Installing the load cell in a climate-controlled area and away from sources of vibration can greatly enhance its reliability. Additionally, check that all electrical connections are secure and free from corrosion, as loose or damaged connections can lead to inaccurate readings.

Finally, always calibrate the load cell before use. Calibration compensates for any installation variances and ensures that the load cell provides precise measurements. Regular re-calibration is also necessary to maintain accuracy over time. By focusing on these installation practices, you can significantly enhance the performance and accuracy of your miniature load cells.

Top Strategies for Enhancing Accuracy with Miniature Load Cells - Common Installation Mistakes to Avoid for Improved Accuracy

| Installation Mistake | Impact on Accuracy | Recommended Strategy | Notes |

|---|---|---|---|

| Incorrect Load Application | Leads to erroneous readings | Use a load guide to ensure proper application | Verify load alignment regularly |

| Poor Electrical Connections | Causes signal interference | Ensure tight and secure connections | Regularly inspect for corrosion |

| Insufficient Calibration | Results in inaccurate measurements | Calibrate using certified weights | Perform calibration at regular intervals |

| Improper Mounting Orientation | Affects load cell performance | Mount according to manufacturer's guidelines | Utilize level indicators during setup |

| Excessive Environmental Vibrations | Can distort readings | Isolate load cells from vibrating sources | Use shock mounts if necessary |

Regular Maintenance Routines to Ensure Long-term Precision of Load Cells

Regular maintenance routines are essential for ensuring the long-term precision of miniature load cells. According to a recent report from the International Society of Automation, approximately 60% of load cell inaccuracies can be attributed to insufficient maintenance practices. Regular calibration checks and adjustments can mitigate drift in measurements and enhance accuracy, helping organizations avoid costly errors in applications such as aerospace and medical device manufacturing.

Implementing a structured maintenance schedule is crucial. This involves routine cleaning to prevent debris accumulation, which can affect sensor performance, and performing periodic calibrations at intervals recommended by manufacturers. Data from the Load Cell Manufacturers Association indicates that companies that adopt stringent maintenance protocols see a 30% improvement in measurement accuracy compared to those that neglect these practices. Additionally, training personnel on proper handling and environmental factors affecting load cell performance can further enhance reliability and lifespan, ultimately leading to more precise and trustworthy measurements in critical operations.

Related Posts

-

Rise of Chinese Manufacturing in Micro Load Cells Amidst US China Tariff Challenges

-

Top 10 Pancake Load Cell Manufacturers from China at the 137th Canton Fair

-

Unlocking Efficiency: Key Advantages of Utilizing Compression Load Cells in Industrial Applications

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide

-

Advantages of Using Low Profile Load Cells for Precision Measurement

-

Ultimate Checklist for Choosing the Best Compression Type Load Cell for Your Business Needs