sales@loadcellsensor.com

sales@loadcellsensor.com

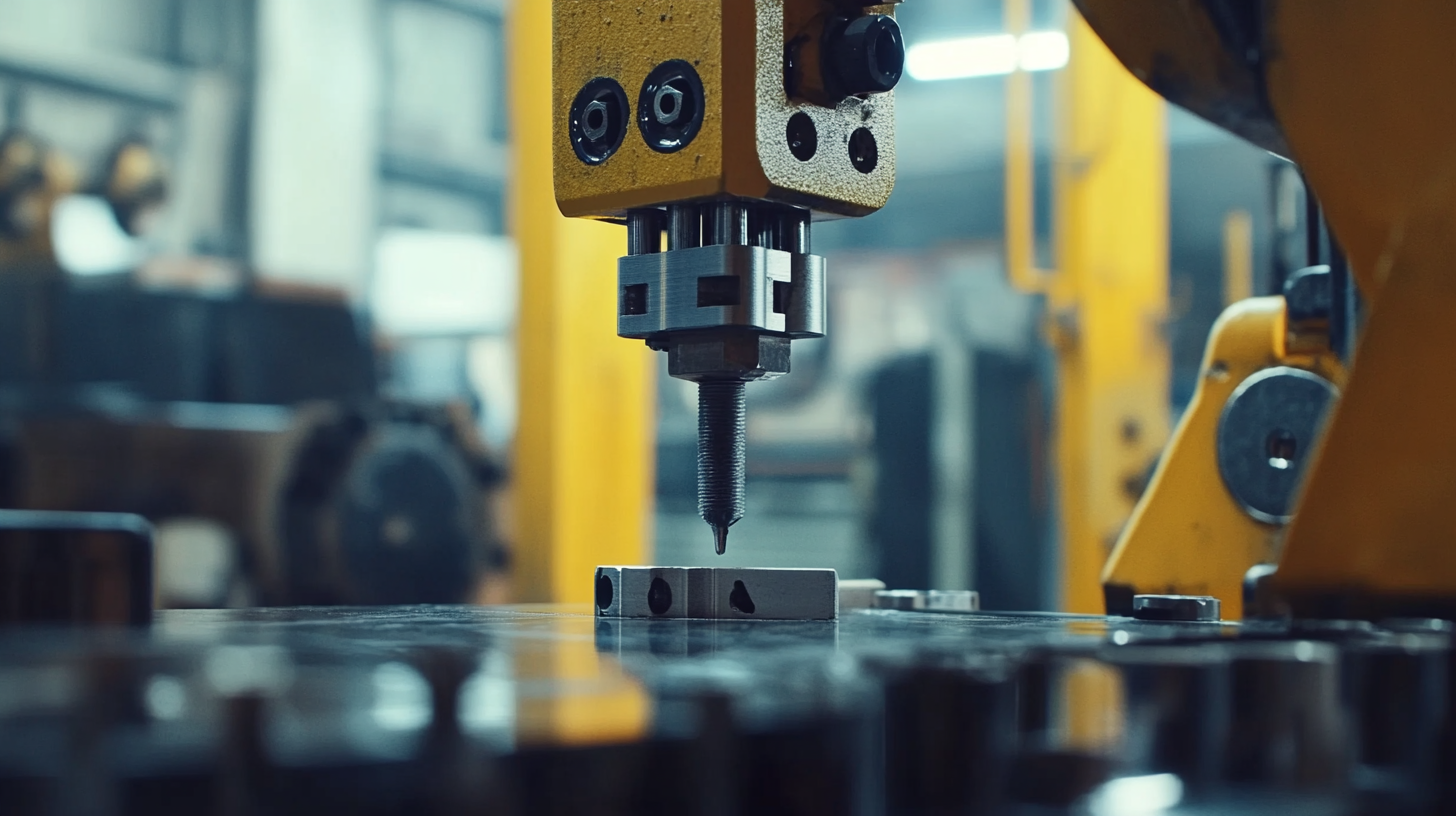

Exploring the Use of Thin Load Cells in Heavy Machinery and Challenges Faced in Precision Measurements

The incorporation of Thin Load Cells in heavy machinery has significantly transformed the approach to precision measurements within industries such as construction, manufacturing, and logistics. According to a recent report from MarketsandMarkets, the global load cell market is expected to reach $3.83 billion by 2025, driven by the increasing demand for accurate weight measurement and monitoring in industrial applications. Thin Load Cells, known for their compact design and high sensitivity, provide a key advantage in limited space environments where conventional load cells may not be feasible. Their accuracy and reliability play a crucial role in maintaining operational efficiency and safety in heavy machinery.

However, the adoption of Thin Load Cells is not without its challenges. Factors such as environmental conditions, calibration complexities, and compatibility with existing machinery and measurement systems can hinder their effectiveness. A study from the International Journal of Precision Engineering and Manufacturing highlighted that discrepancies in measurement can lead to significant financial losses, especially in sectors where precise weight measurement is imperative for quality control and inventory management. As industries continue to evolve, understanding the intricacies of implementing Thin Load Cells will be vital for overcoming these hurdles and enhancing the precision of heavy machinery operations.

The Role of Thin Load Cells in Enhancing Heavy Machinery Performance

Thin load cells are becoming increasingly pivotal in enhancing the performance of heavy machinery. Their compact design and high sensitivity allow for precise weight measurements, which is crucial in minimizing the risk of overloads and ensuring that machines operate within safe limits. This not only prolongs the life of the equipment but also enhances overall efficiency in operations. One of the primary advantages of integrating thin load cells into heavy machinery is their ability to provide real-time data. This data enables operators to monitor load conditions accurately, facilitating better decision-making and operational adjustments. For instance, in industries such as construction and mining, knowing the precise load distribution can significantly affect stability and performance. As machinery works under varying loads, incorporating thin load cells can lead to optimized performance and improved safety procedures. However, there are challenges associated with incorporating thin load cells into heavy machinery. One significant issue is ensuring precision in harsh environments, where vibrations and temperature fluctuations can impact measurements. Furthermore, the installation process requires careful calibration to ensure accuracy, which can be resource-intensive. Despite these challenges, the benefits of using thin load cells in heavy machinery are undeniable, paving the way for innovative solutions that enhance operational efficiency and safety in demanding industrial settings.

Benefits of Precision Measurements in Industrial Applications

Precision measurements play a critical role across various industrial applications, enhancing operational efficiency and product quality. In sectors like agriculture, the integration of technologies such as GPS and automation exemplifies the shift towards precision methods. Precision agriculture enables farmers to optimize crop management by closely monitoring environmental conditions and soil variability. This focused approach not only boosts yield but also conserves resources, making it vital for sustainable farming practices.

The evolution of measurement technologies is equally significant in industrial settings. For instance, advancements in metrology, including the application of generative AI, are redefining accuracy standards. These innovations facilitate dynamic data analytics that enhance quality control and precision, which is essential for manufacturing processes. As industries increasingly adopt these cutting-edge tools, the need for consistent and accurate measurements becomes paramount, particularly in fields like construction and aerospace where margins for error are minimal.

Moreover, the development of precision sensing technologies, such as silicon temperature sensors and Coriolis flow meters, underscores the importance of meticulous measurement in optimizing equipment performance. Companies that prioritize precision in their measurement systems can expect not only improved operational efficiency but also enhanced compliance with evolving industry standards. The focus on precision measurements thus represents a significant avenue for innovation and growth in modern industrial sectors.

Common Challenges in Achieving Accurate Measurements with Thin Load Cells

Thin load cells have increasingly become essential components in heavy machinery due to their capability to provide accurate weight readings in limited spaces. However, achieving precise measurements with these sensors is not without its challenges. One prominent issue is the susceptibility to environmental factors such as temperature fluctuations and humidity. These conditions can cause variations in the measurements, leading to discrepancies that can compromise the integrity of the data collected.

Another challenge arises from the mechanical setup and alignment of the load cells within the machinery. Improper installation can result in load misalignment, which significantly affects the cell's accuracy. Furthermore, the delicate nature of thin load cells means they can be prone to damage from excessive force or vibration, which are common in heavy machinery operations. Regular calibration and careful monitoring are thus critical to maintaining measurement accuracy.

Electrical noise and signal interference also pose challenges when integrating thin load cells into complex machinery systems. The precision of the readings can be distorted by electromagnetic interference, making it difficult to obtain consistent data. Implementing effective shielding and grounding techniques, alongside using high-quality signal conditioners, can help mitigate these issues, allowing for more reliable performance in demanding environments.

Innovative Solutions to Overcome Precision Measurement Issues

In the realm of heavy machinery, precision measurements are crucial for ensuring safety and efficiency. Thin load cells have emerged as a practical solution for weight measurement in these demanding environments. However, the inherent challenges in achieving accuracy with these sensors can lead to significant operational hurdles. Factors such as environmental conditions, load distribution, and the mechanical structure of the machinery itself can all impact the precision of measurements.

To address these challenges, innovative solutions are being developed that enhance the capabilities of thin load cells. For instance, integration with advanced digital signal processing technologies allows for real-time calibration and error correction, which helps mitigate the effects of external variables. Additionally, the use of advanced materials and designs can increase the robustness of load cells, enabling them to perform reliably under extreme conditions. These enhancements not only boost measurement accuracy but also extend the lifespan of the sensors in heavy-duty applications.

Furthermore, the implementation of smart sensors equipped with IoT capabilities is revolutionizing how measurements are monitored. By leveraging data analytics and machine learning algorithms, operators can gain insights into performance trends and potential anomalies. This proactive approach allows for more informed decision-making and maintenance scheduling, ultimately leading to improved precision in measurements and enhanced operational efficiency in heavy machinery applications.

Future Trends in Thin Load Cell Technology for Heavy Equipment

Thin load cells are increasingly becoming essential components in heavy machinery, driven by the need for enhanced precision in weight measurements and data acquisition. As industries push for greater efficiency and accuracy, future trends in thin load cell technology are likely to pivot around advancements in materials and design innovations. Lightweight yet robust materials such as composites and advanced alloys can reduce the overall size of load cells while maintaining, if not enhancing, their sensitivity and durability under extreme conditions typical of heavy equipment operation.

Moreover, the integration of smart technology into thin load cells is set to revolutionize the industry. With the rise of the Internet of Things (IoT), load cells equipped with wireless connectivity and advanced data analytics capabilities can provide real-time monitoring, predictive maintenance alerts, and seamless integration into broader equipment management systems. This technological leap not only helps in tracking operational metrics but also assists in optimizing machinery performance and resource utilization.

As manufacturers respond to the growing demand for precision in heavy machinery, we can expect further innovations that will address current challenges. These may include improved calibration methods, enhanced resistance to environmental factors, and better shock absorption features. The push for sustainability may also lead to the development of load cells that consume less energy while delivering unparalleled performance, ultimately making thin load cell technology a key element in the evolution of heavy equipment manufacturing.