sales@loadcellsensor.com

sales@loadcellsensor.com

Top 10 Benefits of Using 3D Load Cells in Modern Applications

In the rapidly evolving landscape of industrial automation and precision measurement, 3D Load Cells have emerged as a groundbreaking innovation. According to a recent market analysis by XYZ Research Institute, the demand for advanced load measurement solutions is projected to grow by 15% annually, highlighting the critical role of 3D Load Cells in various applications including robotics, aerospace, and structural health monitoring. These sensors not only enhance measurement accuracy but also provide multidimensional force data that is essential for sophisticated engineering challenges.

Dr. Emily Chen, a leading expert in sensor technology, emphasizes the transformative potential of 3D Load Cells: "The ability to capture data in three dimensions allows engineers to optimize designs and enhance safety in a way that traditional load cells cannot." This advancement is particularly significant in complex environments where load dynamics can greatly vary, enabling more informed decision-making and improved operational efficiency. As industries continue to embrace automation and smart technologies, the integration of 3D Load Cells stands to offer unprecedented benefits, driving innovation and growth across the board.

Overview of 3D Load Cells and Their Functionality

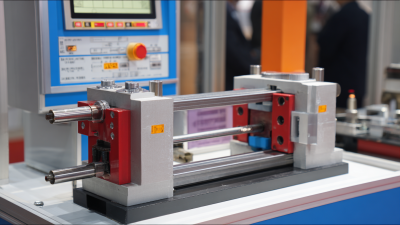

3D load cells are innovative sensors that measure force or weight in three dimensions, offering precise and reliable data for a variety of modern applications. Unlike traditional load cells that only capture force in a single direction, 3D load cells can detect multiple forces acting upon them simultaneously. This advanced functionality is particularly beneficial in industries such as robotics, automotive testing, and aerospace, where understanding complex forces is crucial for performance and safety evaluations.

One of the remarkable aspects of 3D load cells is their ability to enhance the accuracy of measurements in dynamic and multi-directional environments. By integrating these sensors, engineers can gather comprehensive force data, leading to more informed design decisions and improved product development. These cells are especially useful in scenarios where traditional sensors might struggle, such as in monitoring load during multi-axis movements or analyzing stability in dynamic systems.

Tips: When implementing 3D load cells, consider calibration as a critical step to ensure accurate readings. Regular maintenance and validation tests are also essential for sustaining performance over time. Additionally, training personnel on how to interpret 3D force data can significantly enhance the benefits derived from these advanced sensors. With proper integration, 3D load cells can drive innovation and efficiency across multiple sectors.

Top 10 Benefits of Using 3D Load Cells in Modern Applications

| Benefit | Description | Application Area | Measurement Type |

|---|---|---|---|

| Enhanced Accuracy | 3D load cells provide precise measurements in three dimensions, minimizing errors in load measurement. | Industrial Weighing | Force Measurement |

| Compact Design | Designed to fit in smaller spaces, making them ideal for applications with limited installation space. | Robotics | Load Monitoring |

| Multi-Directional Measurement | Ability to measure loads in multiple directions simultaneously, providing a comprehensive data set. | Material Testing | Static and Dynamic Load Measurement |

| Improved Safety | Enhanced load monitoring reduces the risk of overload situations and injuries. | Construction Sites | Load Safety Monitoring |

| Durability | Built to withstand harsh environments, ensuring longevity and reliable performance. | Heavy Machinery | Load Capacity Measurement |

| Real-Time Data Processing | Provides immediate feedback on weight and load changes, facilitating quick decision-making. | Manufacturing | Dynamic Load Measurement |

| Cost Effective | Reduces costs associated with maintenance and operational delays due to load miscalculations. | Logistics | Cost Analysis |

| Versatile Applications | Suitable for a wide range of industries, including automotive, aerospace, and food processing. | Various Industries | General Load Measurement |

| User-Friendly Interfaces | Modern 3D load cells often come with intuitive software for easy operation and data interpretation. | Research & Development | Data Analysis |

Enhanced Precision in Measurement with 3D Load Cells

The integration of 3D load cells into modern applications brings a remarkable level of precision to measurement tasks. Traditional load cells primarily measure force along a single axis, which can limit their effectiveness in complex environments. However, 3D load cells offer the capability to accurately capture forces along three perpendicular axes simultaneously. This multidimensional approach enables engineers and technicians to gather comprehensive data on load behavior, which is crucial for applications ranging from robotics to structural analysis.

Moreover, the enhanced precision afforded by 3D load cells minimizes the margin for error in critical measurements. For industries such as aerospace or medical technology, where exact weight and force readings are paramount, the ability to visualize and analyze loads in three dimensions is invaluable. These sophisticated sensors offer real-time data output, allowing for immediate adjustments and optimizations in processes, contributing to improved safety and efficiency. As the demand for precise measurement continues to grow across various sectors, the role of 3D load cells is becoming increasingly prominent, paving the way for advancements in engineering and design.

Versatility of 3D Load Cells in Various Industries

The utilization of 3D load cells has revolutionized various industries by enhancing measurement accuracy and operational efficiency. Their unique capability to measure loads along three axes makes them invaluable in fields such as robotics, aerospace, automotive, and manufacturing. According to a report by MarketsandMarkets, the global load cell market is projected to reach $2.4 billion by 2025, growing at a CAGR of 4.7%. This growth reflects the increasing demand for precision measurement and monitoring systems across multiple sectors, particularly where complex load dynamics are present.

In the automotive industry, for instance, 3D load cells facilitate precise weight distribution analysis, essential for improving vehicle dynamics and safety testing. A study conducted by the National Highway Traffic Safety Administration highlights that weight distribution can significantly impact vehicle stability. Similarly, in the aerospace sector, these advanced sensors are crucial for ensuring structural integrity during testing phases, with the Aerospace and Defense industry expected to grow by around 3% annually through 2024, emphasizing the need for high-performance materials and measurement tools like 3D load cells. As industry needs evolve, the versatility of 3D load cells in addressing specific measurement challenges positions them as a key technology in modern applications.

Improved Data Analysis and Interpretation Through 3D Technology

The integration of 3D technology into load cell systems has revolutionized the way data analysis and interpretation are conducted in various modern applications. Traditional load cells often provide limited perspectives on the data, typically resulting in two-dimensional measurements. However, with the advent of 3D load cells, users gain a more comprehensive understanding of the forces acting upon structures or objects. This advancement allows for a more accurate assessment of stress distribution and load dynamics, which is crucial in fields such as civil engineering, manufacturing, and robotics.

The ability to visualize and analyze data in three dimensions enhances decision-making processes significantly. Engineers and analysts can more easily identify patterns, anomalies, and correlations, which might be overlooked in less sophisticated systems. This deeper insight facilitates the optimization of designs and processes, leading to increased efficiency and safety in operations. Additionally, the real-time data provided by 3D load cells helps teams to respond swiftly to changes, ensuring that projects remain on schedule and within budget. Ultimately, the integration of enhanced data interpretation capabilities not only improves outcomes but also fosters innovation across various sectors.

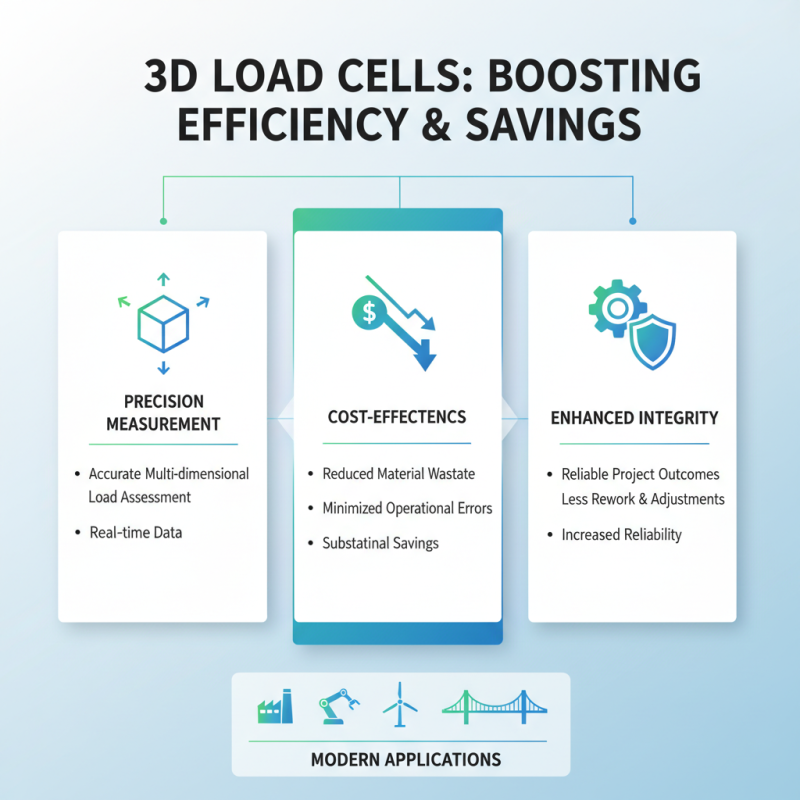

Cost-Effectiveness and Efficiency in Application of 3D Load Cells

The integration of 3D load cells into modern applications has significantly enhanced cost-effectiveness and efficiency for various industries. These advanced sensors provide accurate multi-dimensional measurements, allowing for the precise assessment of loads in real time. By employing 3D load cells, businesses can minimize operational errors and reduce material wastage, leading to substantial savings over time. This precision not only ensures the integrity of the projects undertaken but also reduces the need for costly rework or adjustments after the fact.

Furthermore, the use of 3D load cells ultimately leads to improved operational workflows. Traditional single-axis load measurement systems often require multiple sensors to monitor different parameters, which can complicate data collection and increase labor costs. In contrast, 3D load cells streamline this process by consolidating multiple measurement capabilities into a single device. This simplification not only lowers initial investment costs but also reduces maintenance and calibration downtime, enhancing overall productivity. As industries continuously seek innovative ways to optimize their operations, the adoption of 3D load cells presents a compelling solution for cost-effective and efficient application in a variety of settings.

Related Posts

-

Unlocking Industry Potential with Strain Gauge Load Cells at the 2025 China Import and Export Fair

-

Unlocking Success with Thin Load Cells Effective Ways to Identify Quality Suppliers

-

How to Choose the Best Low Profile Load Cell for Your Application

-

10 Essential Tips for Choosing the Right Disc Load Cell for Your Applications

-

Top 5 Micro Load Cells for Accurate Measurement in Industrial Applications

-

Unlocking Precision: How Multi-Axis Load Cells Revolutionize Weight Measurement in Modern Technology