sales@loadcellsensor.com

sales@loadcellsensor.com

Top 10kg Load Cell Applications You Should Know About?

Load cells are essential in many industries. They measure weight with precision and offer various applications. The 10kg load cell stands out due to its versatility. From laboratory experiments to industrial scales, its importance cannot be overstated.

In some cases, users may overlook the impact of proper calibration. Without regular checks, readings can be inaccurate. This oversight leads to errors in important data. Industries relying on precision must address these potential pitfalls. The 10kg load cell can transform efficiency when used correctly.

Whether in shipping, packaging, or research, understanding its applications is crucial. Many people may not know how widespread the use of load cells is. Their significance in weighing systems is profound yet often unappreciated. Taking time to explore the top uses of a 10kg load cell reveals its hidden potential.

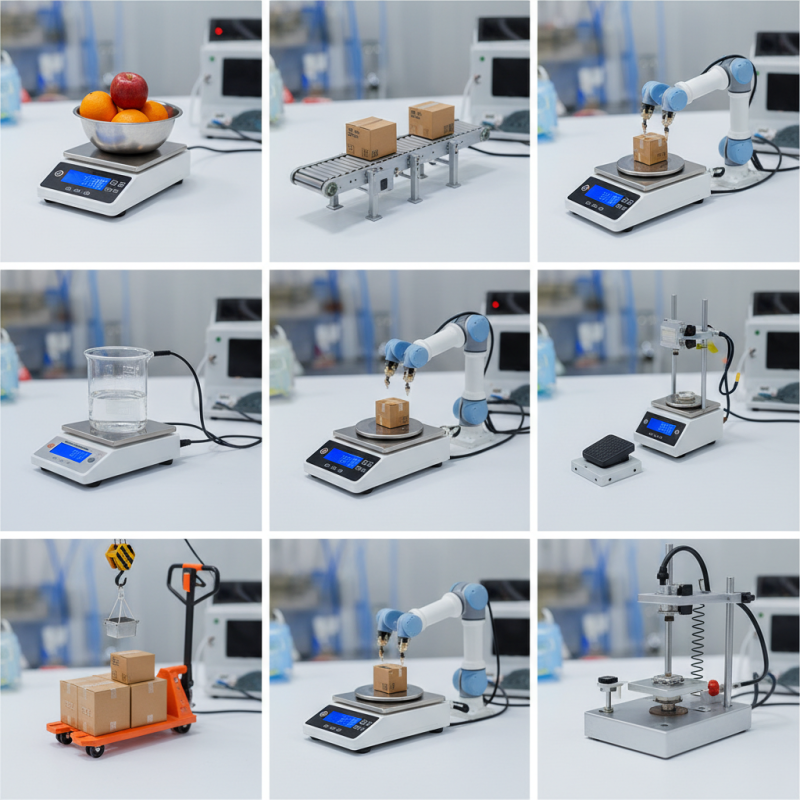

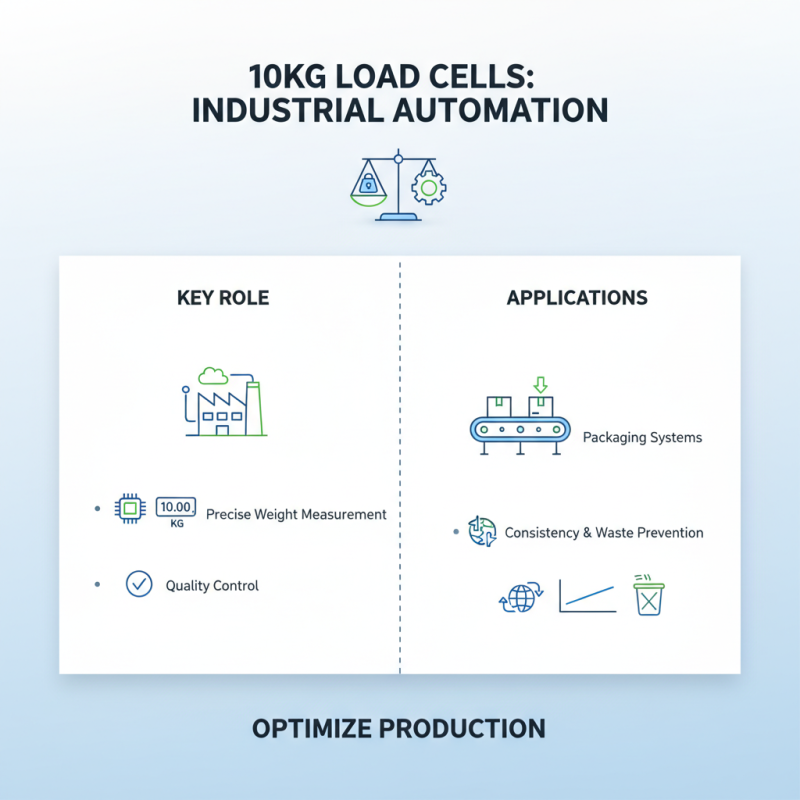

Top Applications of 10kg Load Cells in Industrial Automation

Load cells play a critical role in industrial automation, particularly the 10kg load cell. They offer precise weight measurements in various applications. One common use is in packaging systems. These systems require accurate weight data to ensure consistency and prevent waste. The 10kg load cell helps maintain quality control during production.

Another application is in conveyor systems. Here, 10kg load cells monitor the weight of products as they move along the line. This information can automate sorting and handling processes. It ensures that no load exceeds capacity, which can lead to equipment damage. However, calibration errors with load cells can occur, resulting in inaccurate readings.

In food processing, 10kg load cells are essential. They are used in batching ingredients for recipes. This requires not only precision but also compliance with safety standards. Improper use or failure to calibrate can affect product quality. Reflection on the integration of load cells urges manufacturers to implement regular checks. Incorporating these practices can enhance performance and reliability in automation systems.

Utilizing 10kg Load Cells in Packaging and Filling Machines

In the packaging and filling machines industry, 10kg load cells play a critical role. They are essential for accurate weight measurement in automated processes. According to a report by Market Research Future, the demand for load cells is projected to grow at a CAGR of 5.5% from 2021 to 2027. This trend reflects the industry's need for precise measurements during operations.

Utilizing 10kg load cells in filling machines enhances efficiency. These devices provide real-time feedback, ensuring that products are filled correctly. Even small discrepancies can lead to waste. An inaccurate fill can compromise product quality and result in financial losses. Some companies have reported errors of up to 3% without using high-quality load cells.

Another aspect to consider is the calibration of these load cells. They require regular checks to ensure accuracy. Neglecting maintenance can result in equipment failure or regulatory issues. The operational costs might rise if companies overlook this. Thus, investing in proper training for personnel is critical. Ultimately, the integration of 10kg load cells improves overall productivity but must be managed carefully.

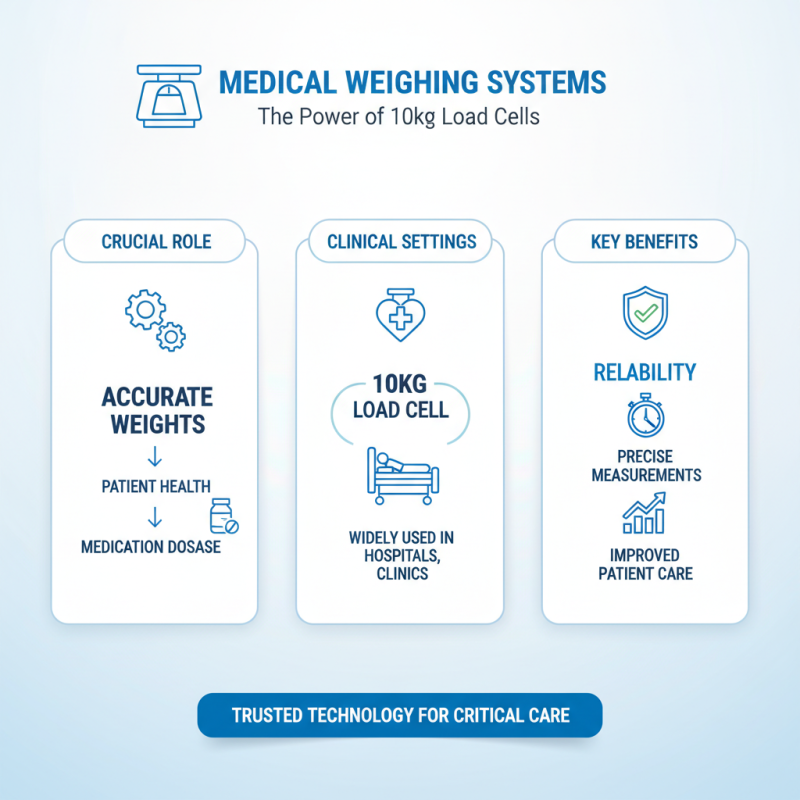

The Role of 10kg Load Cells in Medical Equipment Weighing Systems

Load cells play a crucial role in weighing systems for medical equipment. Specifically, the 10kg load cell is widely used in clinical settings. These devices ensure accurate weight measurements for patients, which is vital for proper medication dosage and health assessments.

In hospitals, load cells are integrated into scales. They help in monitoring changes in patient weight over time. This data can be essential for tracking health conditions, such as weight loss or gain. However, inaccuracies can occur. Calibration errors or mechanical wear may lead to false readings. Regular maintenance is necessary to mitigate these issues.

Moreover, load cells contribute to the efficiency of portable medical devices. Lightweight and compact, they are easily incorporated into home healthcare systems. This convenience allows patients to monitor their weight without visiting a clinic. It fosters independence, yet reliance on the device’s accuracy raises concerns. Users must remain vigilant to verify results regularly.

Integrating 10kg Load Cells into Robotics for Precision Measurement

Integrating 10kg load cells into robotics offers unmatched precision. These sensors measure force and weight accurately, which is crucial for robotic applications. A recent study shows that precision in robotics can improve efficiency by up to 30%. This statistic highlights the importance of load cell integration.

In robotics, load cells provide real-time feedback. This helps robots adjust their actions based on the weight they handle. For example, a robot arm equipped with a 10kg load cell can detect changes in load and respond instantly. Such responsiveness enhances operational safety and reduces the risk of damage to both the robot and its environment.

However, challenges remain. Calibration of load cells can be complex. In some cases, sensors may deliver inconsistent readings if not maintained correctly. Regular checks on sensor performance are vital. A 2022 industry report indicated that nearly 15% of load cell failures are linked to poor calibration practices. This calls for greater attention to detail in maintenance routines.

Top 10kg Load Cell Applications You Should Know About

| Application | Description | Key Benefits | Industry |

|---|---|---|---|

| Robotics & Automation | Integrating load cells to ensure precise measurement of robotic arm movements and force application. | Enhanced accuracy, improved efficiency, better force control. | Manufacturing |

| Weighing Systems | Used in scales for accurate weight measurement in retail and industrial settings. | Precision in weight measurement, reliability, user-friendly interfaces. | Retail, Logistics |

| Load Monitoring | Monitor loads on structures to prevent overload and ensure safety. | Increased safety, real-time monitoring, damage prevention. | Construction, Engineering |

| Research & Development | Utilized in R&D for testing material strength and product performance. | Accurate data collection, supports innovation, versatile application. | Academic, Industrial R&D |

| Medical Devices | Incorporated into medical scales and diagnostic devices for accurate patient measurements. | Improved patient care, accuracy in diagnostics, compliance with healthcare standards. | Healthcare |

| Material Testing | For testing tensile strength and load capacity of various materials. | Supports quality control, identifies material properties, enhances product design. | Manufacturing, Construction |

| Industrial Automation | Used in automated production lines for real-time weight feedback. | Boosts productivity, minimizes human error, ensures quality control. | Manufacturing, Food & Beverage |

| Force Measurement | Measures the specific force applied in various applications. | Accurate force data, aids in research, diverse application scope. | Engineering, Testing |

| Agricultural Equipment | Used in electronic scales for farming inputs and produce. | Improved accuracy, better farm management, and resource allocation. | Agriculture |

| Packaging Industry | Ensuring accurate weights during packaging processes. | Reduces wastage, ensures compliance with regulations, enhances quality assurance. | Manufacturing, Retail |

10kg Load Cells in Load Testing and Structural Analysis Applications

Load cells are essential for precise measurements in load testing and structural analysis. A 10kg load cell provides accurate data essential for evaluating the integrity of various structures. In construction, engineers rely on these devices to assess material strength. A report from the International Society for Structural Engineering indicates that over 30% of structural failures are linked to improper load calculations.

Using 10kg load cells ensures that the limits of material strength are not exceeded. This is crucial in industries where safety is paramount. In laboratory settings, load tests simulate real-world conditions. These tests can reveal faults not visible to the naked eye. According to a recent study, nearly 25% of material testing cases either over or underutilize load capacity, leading to possible failures.

Implementing load cells can sometimes feel monotonous. Yet, the data they provide is invaluable. Engineers face challenges ensuring that their testing methods are consistently accurate. Instructive feedback from past tests can guide future practice. It's vital for professionals to remain vigilant. An unexpected failure can lead to significant consequences.

Related Posts

-

5 Essential Tips for Choosing the Right Thin Load Cell

-

Understanding Import Export Certifications for Best Thin Load Cells with a Comprehensive Tutorial Guide

-

Advantages of Using Low Profile Load Cells for Precision Measurement

-

Top Pancake Load Cell Applications in Industry and Science?

-

2025 How to Choose the Right Hollow Load Cell for Accurate Measurements

-

Understanding Inline Load Cells: Revolutionizing Weight Measurement in Modern Industries