sales@loadcellsensor.com

sales@loadcellsensor.com

Why Torque Sensors Are Essential for Accurate Force Measurement?

In modern engineering, precision is essential. Torque sensors play a crucial role in achieving accurate force measurement. These devices monitor torque levels in various applications. They ensure the integrity and performance of machines. Without them, discrepancies can arise, leading to costly errors.

The importance of torque sensors cannot be overstated. For instance, in automotive testing, even the smallest miscalculation can lead to failure. Engineers rely heavily on these sensors to calibrate components effectively. A faulty measurement can undermine trust in data. It is vital to reflect on how often we overlook their importance.

Torque sensors are integral to innovation. They evolve with technology, adapting to new challenges. However, their complexity can lead to errors if not properly managed. Understanding the limits of these devices is necessary. We must appreciate their contribution while recognizing potential shortcomings in measurements.

Importance of Torque Sensors in Industrial Applications

Torque sensors play a critical role in various industrial applications. They provide precise measurements of torque. This is vital for ensuring that machines operate effectively. Accurate force measurement helps prevent equipment failure. It can also increase safety in the workplace.

In manufacturing, torque sensors monitor the assembly of products. They ensure that parts are tightened correctly. This reduces the risk of malfunction and costly recalls. Many industries depend on these tools for quality control.

**Tips:** When selecting a torque sensor, consider the environment. Temperature extremes can affect accuracy.

Proper installation is equally important. Misalignment can lead to incorrect readings. Regular calibration is necessary to maintain precision.

Ensure data shows real-time monitoring. This allows for quick response to potential issues. By understanding these factors, industries can optimize their operations.

Key Technologies Behind Torque Sensor Accuracy

When it comes to torque sensors, precision is everything. Various technologies contribute to accurate torque measurement. Strain gauge technology, for example, is widely used for its reliability. According to a recent industry report, sensors incorporating strain gauges can achieve an accuracy of up to 0.1%. This level of precision is crucial in industries where even minor discrepancies can lead to significant operational issues.

Another important technology is the capacitive method. This method works by measuring the change in capacitance caused by torque. It offers less sensitivity to environmental factors, which is a notable advantage. Reports suggest that sensors using this technology can maintain accuracy even under extreme conditions. However, one must consider the potential for drift over time with capacitive sensors.

Tips: Regular calibration can enhance the accuracy of torque sensors. Additionally, monitoring ambient conditions helps mitigate measurement errors. It's also essential to choose the right sensor based on the specific application to ensure optimal performance. A poorly matched sensor can lead to unreliable data, so careful selection is necessary. Keeping an eye on technological advancements can also guide you towards improved solutions in torque measurement.

Why Torque Sensors Are Essential for Accurate Force Measurement? - Key Technologies Behind Torque Sensor Accuracy

| Parameter | Value | Unit |

|---|---|---|

| Torque Range | 0 - 100 | Nm |

| Accuracy | ±0.5 | % |

| Resolution | 0.01 | Nm |

| Operating Temperature | -20 to 80 | °C |

| Output Signal Type | Analog | |

| Sensor Type | Strain Gauge | |

| Power Supply | 5-15 | V |

Quantifying Force Measurement: Torque Sensors vs. Alternative Methods

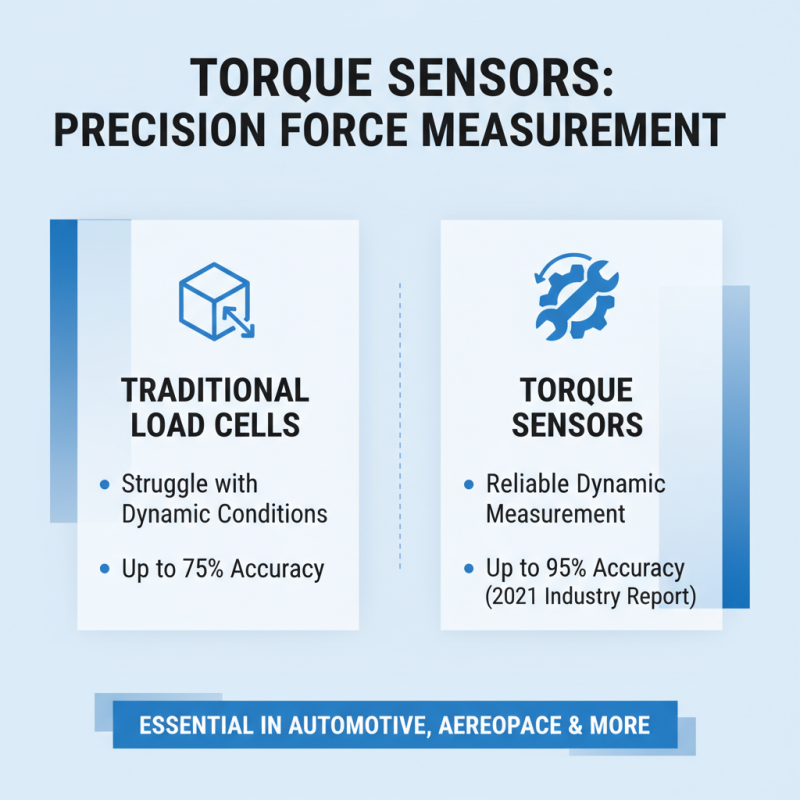

Torque sensors play a crucial role in force measurement. They provide reliable data that is essential in various applications, from automotive to aerospace. Traditional methods, such as load cells, often struggle with precise measurements during dynamic conditions. According to a 2021 industry report, torque sensors can offer up to 95% accuracy in measurements compared to 75% with load cells.

Moreover, torque sensors excel in capturing data in real-time. Their ability to measure torque directly makes them more effective. Studies indicate that using torque sensors can reduce the risk of measurement errors associated with indirect methods. This shift in measurement strategy can lead to a significant reduction in product failures, which cost industries millions annually.

Despite their advantages, torque sensors are sometimes underutilized. Some manufacturers remain hesitant due to cost and complexity. Yet, the benefits they provide can outweigh the initial investment. Understanding how to integrate these sensors into existing systems can enhance overall measurement accuracy. Embracing advancements in torque sensing technology could be the key to improving operational efficiency and safety across various industries.

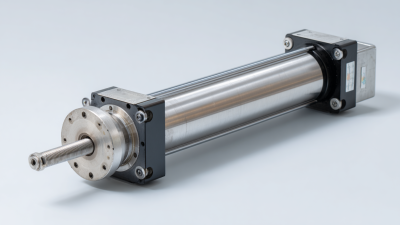

Impact of Accurate Torque Measurement on Machinery Performance

Accurate torque measurement plays a crucial role in machinery performance. It ensures that components work seamlessly together. When torque is improperly measured, machinery can suffer. This can lead to inefficiencies, increased wear, or even catastrophic failures. For instance, a poorly calibrated torque sensor can cause a bolt to loosen over time. This creates safety hazards and costly downtime.

Tips for achieving accurate torque measurement include regular calibration of sensors. It’s important to check settings to avoid misreading. Using high-quality equipment is also essential. However, sometimes even the best equipment can fail. So, it's wise to have a backup system in place. A detailed inspection of machinery should not be overlooked. Look for any signs of wear or misalignment.

Inconsistent torque readings can be a red flag. It's beneficial to track measurements over time. This can reveal patterns that indicate issues. Regular maintenance can help prevent problems. However, recognizing that not all machinery operates perfectly is key. Embracing imperfections allows for proactive solutions and better outcomes. Be open to feedback from operators. Their insights can help refine measurement techniques.

Torque Sensors Performance Impact on Machinery Efficiency

Accurate torque measurement is crucial for maintaining optimal machinery performance. As seen in the chart, higher torque accuracy directly correlates with increased efficiency, demonstrating the importance of using precision torque sensors in industrial applications.

Emerging Trends in Torque Sensor Development and Market Growth

The torque sensor market is witnessing significant growth. According to a recent report, the global torque sensor market is expected to reach USD 1.12 billion by 2027, growing at a CAGR of 5.2%. This growth is driven by increased demand in automotive, aerospace, and industrial applications.

Advanced technologies like wireless communication and IoT integration are shaping the future of torque sensors, offering greater flexibility and efficiency.

Emerging trends point towards miniaturization and enhanced accuracy. Manufacturers strive for smaller, yet more powerful sensors. This poses challenges in maintaining precision. While innovations are impressive, achieving standardized quality across various products remains a concern. Additionally, as industries shift towards automation, the need for reliable torque measurements becomes crucial for effective performance.

The rise in electric vehicle production also contributes to the market expansion. Torque sensors are vital in monitoring motor performance. However, the integration of these sensors in complex systems can be daunting. Data from the industry suggests that nearly 70% of errors in torque measurement stem from installation flaws. This highlights the need for improved user training and better installation practices across sectors.

Related Posts

-

Maximizing Precision: Key Techniques for Effective Torque Sensor Implementation

-

Exploring Innovative Torque Sensor Types: Real-World Applications and Benefits

-

Understanding the Basics of Torque Sensor Functionality and Applications

-

How to Choose the Right Torque Sensor for Your Applications

-

Unleashing China's Manufacturing Excellence: A Deep Dive into the Best Torque Sensor Innovations

-

Navigating the Global Standards for Best Torque Sensor Imports and Exports