sales@loadcellsensor.com

sales@loadcellsensor.com

5 Compelling Reasons Why Torque Sensors Revolutionize Industrial Applications

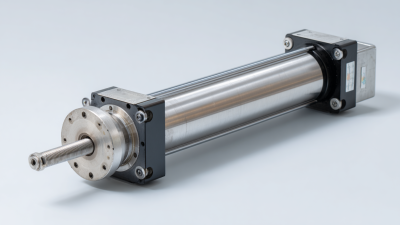

In today's rapidly evolving industrial landscape, the demand for precision and efficiency is more critical than ever. Torque sensors, which measure the rotational force applied to an object, have emerged as indispensable tools in various applications, from automotive manufacturing to aerospace engineering. According to a recent report by MarketsandMarkets, the global torque sensor market is projected to reach USD 2.3 billion by 2025, driven by the growing need for automation and real-time monitoring in industrial processes. As industries strive for enhanced performance and reliability, the implementation of torque sensors is revolutionizing how machines operate, enabling businesses to optimize their workflows, reduce downtime, and improve safety standards. This blog will explore five compelling reasons why torque sensors are transforming industrial applications and why investing in this technology is increasingly seen as a strategic imperative.

The Role of Torque Sensors in Enhancing Precision in Industrial Machinery

Torque sensors are instrumental in enhancing precision in industrial machinery, providing manufacturers with crucial data to improve performance and efficiency. By accurately measuring the amount of torque being exerted, these sensors enable real-time adjustments during operations, leading to optimized processes and reduced downtime. This level of precision is particularly beneficial in applications where consistent performance is key, such as in automotive assembly lines or robotics.

Tip: Implement regular calibration of torque sensors to maintain their accuracy. Even minor deviations can lead to significant errors in high-precision tasks.

Moreover, torque sensors contribute to predictive maintenance strategies, allowing companies to identify potential issues before they lead to costly failures. By analyzing torque data, maintenance teams can better understand when a machine is likely to require repairs, ultimately leading to enhanced equipment longevity and reduced operational disruptions.

Tip: Analyze torque trends over time to spot anomalies that may indicate wear and tear. Early detection is crucial for maintaining optimal machinery performance.

Key Industry Data Supporting the Efficiency Gains from Torque Sensors

The integration of torque sensors into industrial applications has shown remarkable efficiency gains, backed by a variety of industry data. According to a recent report by the International Society of Automation, businesses that have adopted torque sensing technology have experienced up to a 30% reduction in energy consumption. This significant decrease is attributed to the sensors’ ability to provide real-time feedback, enabling operators to optimize machinery performance and reduce unnecessary wear and tear on equipment.

Furthermore, a study by the Manufacturing Technology Association revealed that the use of torque sensors can lead to up to a 25% increase in production throughput. By accurately measuring torque during manufacturing processes, companies can identify inefficiencies and implement corrective actions swiftly. The data indicates that industries ranging from automotive to aerospace have reaped substantial benefits, as precise torque measurements directly correlate with improved product quality and reduced scrap rates, fostering a more sustainable manufacturing environment. These findings highlight the transformative potential of torque sensors in driving operational excellence across various sectors.

How Torque Sensors Drive Predictive Maintenance Strategies in Manufacturing

Torque sensors are at the forefront of transforming industrial applications, especially in driving

predictive maintenance strategies.

With their ability to provide real-time torque data,

these sensors enable manufacturers to monitor equipment performance continuously. This proactive approach allows

organizations to address potential issues before they escalate, significantly reducing unplanned downtime—an issue that can cost manufacturers up to

20% of their productivity.

Integrating machine learning and AI with torque sensors further enhances predictive maintenance efforts. By analyzing torque data, companies can implement stochastic modeling techniques to predict equipment failures with remarkable accuracy. Reports indicate that businesses utilizing predictive maintenance strategies have achieved maintenance cost reductions of up to

30%, while also extending equipment lifespan.

Tips:

Regularly calibrate torque sensors to ensure accurate readings and improve the effectiveness of your predictive maintenance program. Additionally, leveraging digital twin technology can help visualize real-time data, making it easier to identify and resolve potential issues in the production line. Embracing these innovations positions manufacturers to thrive in the era of Industry 4.0, ultimately leading to smarter manufacturing processes.

The Impact of Torque Sensors on Reducing Operational Costs and Downtime

Torque sensors are transforming industrial applications by significantly reducing operational costs and downtime. By providing real-time data on torque, these sensors enable manufacturers to optimize equipment performance and prevent failures before they occur. This proactive monitoring leads to improved reliability of machinery, which is crucial in minimizing the frequency and duration of downtime, ultimately enhancing productivity.

Tips for implementing torque sensors effectively include prioritizing their integration into critical machinery and processes that often experience wear and tear. Regular calibration and maintenance of these sensors also ensure accurate readings, leading to better decision-making. Additionally, combining torque sensors with AI-driven predictive maintenance can further boost efficiency, as AI algorithms can analyze torque data to anticipate potential equipment failures, allowing for timely interventions.

Furthermore, investing in advanced torque sensors can also lead to substantial savings on operational costs. By reducing the likelihood of unexpected breakdowns and maintenance needs, businesses can allocate resources more efficiently and maintain smoother operations. Adopting this technology not only modernizes manufacturing processes but also contributes to a more sustainable economic model in the industry.

Real-World Applications: Torque Sensors Revolutionizing Quality Control Processes

Torque sensors have emerged as a crucial innovation in enhancing quality control processes across various industrial sectors. By providing real-time data on torque measurements, these sensors enable manufacturers to ensure that assembly operations meet stringent quality standards. In applications such as automotive and aerospace, precision is vital; even slight deviations in torque can lead to catastrophic failures. Torque sensors facilitate the monitoring of assembly tools, ensuring that each component is tightened to the specified parameters, thereby improving product reliability and safety.

Moreover, the integration of torque sensors into production lines streamlines the quality assurance process. Automated systems equipped with these sensors can rapidly detect discrepancies and immediately alert operators, reducing the risk of defective products reaching the market. This immediate feedback loop not only enhances operational efficiency but also fosters a culture of continuous improvement. As industries increasingly prioritize quality and safety, torque sensors stand at the forefront, driving innovations that transform how manufacturers uphold their standards.

Related Posts

-

Precision Engineering: Chinese Manufacturing Innovating Global Torque Transducer Solutions

-

Maximizing Precision: Key Techniques for Effective Torque Sensor Implementation

-

Global Sourcing Revolution: How China's Best Thin Load Cells Set the Standard for Quality and Reliability

-

Advantages of Utilizing Ring Load Cells for Precise Industrial Measurements

-

Discovering the Future of Precision: Button Load Cells at the 2025 Canton Fair

-

Enhancing User Experience: The After-Sales Service and Maintenance Cost Benefits of the Best Load Cell Sensor